Anti-aging moisturizing essence and preparation process thereof

A preparation process and essence technology, applied in the field of skin care products, can solve problems such as damage to human organs and functions, skin allergies, etc., and achieve the effects of improving skin, soothing wrinkles, and delaying skin aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

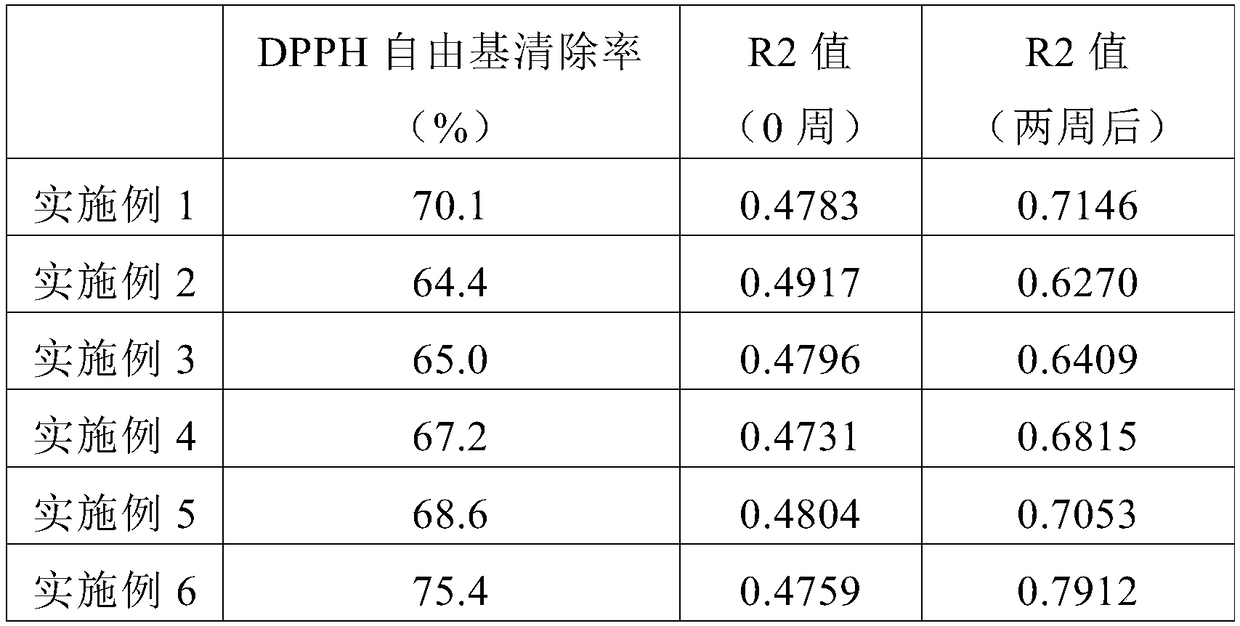

Examples

Embodiment 1

[0028] The preparation process of the anti-aging moisturizing essence comprises the following steps:

[0029] Add 0.5 parts by weight of hydroxyethyl urea, 1.5 parts by weight of glycerin, 0.1 parts by weight of carbomer, 6 parts by weight of 1,3-propanediol, 0.5 parts by weight of 1,2-hexanediol, and 0.05 parts by weight of sodium hyaluronate into 80 Parts by weight of deionized water were stirred at a temperature of 75°C at a speed of 300r / min for 10 minutes and mixed evenly. After cooling to 40°C, 0.1 parts by weight of triethanolamine was added and stirred at a speed of 300r / min for 3 minutes. Dextran, 0.5 parts by weight of betaine, 20 parts by weight of plant extracts, 0.6 parts by weight of N-maleoylated-O-carboxymethyl chitosan are mixed evenly with a rotating speed of 300r / min for 25min to obtain anti-aging moisturizing Essence.

[0030] The β-glucan is oat β-glucan.

[0031] The carbomer is carbomer 940.

[0032] The preparation method of the plant extract is as f...

Embodiment 2

[0034] The preparation process of the anti-aging moisturizing essence comprises the following steps:

[0035] Add 0.5 parts by weight of hydroxyethyl urea, 1.5 parts by weight of glycerin, 0.1 parts by weight of carbomer, 6 parts by weight of 1,3-propanediol, 0.5 parts by weight of 1,2-hexanediol, and 0.05 parts by weight of sodium hyaluronate into 80 Parts by weight of deionized water were stirred at a temperature of 75°C at a speed of 300r / min for 10 minutes and mixed evenly. After cooling to 40°C, 0.1 parts by weight of triethanolamine was added and stirred at a speed of 300r / min for 3 minutes. Dextran, 0.5 parts by weight of betaine, 20 parts by weight of plant extracts, 0.6 parts by weight of N-maleoylated-O-carboxymethyl chitosan are mixed evenly with a rotating speed of 300r / min for 25min to obtain anti-aging moisturizing Essence.

[0036] The β-glucan is oat β-glucan.

[0037] The carbomer is carbomer 940.

[0038]The preparation method of the plant extract is as fo...

Embodiment 3

[0040] The preparation process of the anti-aging moisturizing essence comprises the following steps:

[0041] Add 0.5 parts by weight of hydroxyethyl urea, 1.5 parts by weight of glycerin, 0.1 parts by weight of carbomer, 6 parts by weight of 1,3-propanediol, 0.5 parts by weight of 1,2-hexanediol, and 0.05 parts by weight of sodium hyaluronate into 80 Parts by weight of deionized water were stirred at a temperature of 75°C at a speed of 300r / min for 10 minutes and mixed evenly. After cooling to 40°C, 0.1 parts by weight of triethanolamine was added and stirred at a speed of 300r / min for 3 minutes. Dextran, 0.5 parts by weight of betaine, 20 parts by weight of plant extracts, 0.6 parts by weight of N-maleoylated-O-carboxymethyl chitosan are mixed evenly with a rotating speed of 300r / min for 25min to obtain anti-aging moisturizing Essence.

[0042] The β-glucan is oat β-glucan.

[0043] The carbomer is carbomer 940.

[0044] The preparation method of the plant extract is as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com