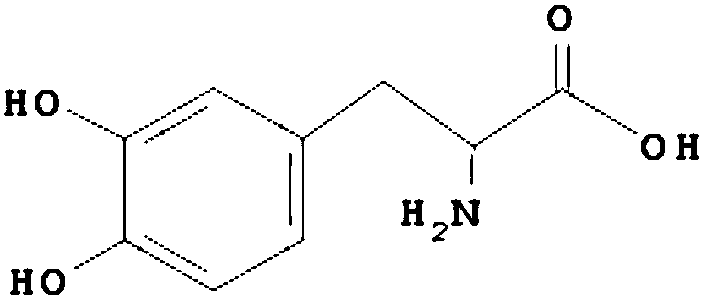

Method for improving quality and yield of 3,4-dihydroxyphenyl-L-ananine products

A technology of product quality and levodopa, applied in the field of enzyme catalysis process, can solve the problems of reducing the yield of L-DOPA, the impact of product quality, etc., to achieve the improvement of conversion rate and product yield, improve product quality, and avoid oxygen oxidation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0015] Example: Conversion of Tyrosine Phenol Lyase to L-Dopa

[0016] 1) 1L substrate solution: boil tap water, pass nitrogen gas and cool down to 25°C, first add 2g / L sodium sulfite and 1g / L ascorbic acid, then add 14g / L sodium pyruvate, 10g / L catechol, 60g / L ammonium acetate, 1g / L EDTA, adjust the pH to 8.0, and keep nitrogen;

[0017] 2) 1L feeding solution: boil tap water, pass nitrogen gas and cool down to 25°C, first add 2g / L sodium sulfite and 1g / L ascorbic acid, then add 140g / L sodium pyruvate and 140g / L catechol , 20g / L of ammonium acetate, 1g / L of EDTA, adjust the pH to 8.0, seal, and keep nitrogen, and maintain positive pressure;

[0018] 3) Obtain 10-100g of tyrosine phenol lyase enzyme solution by fermentation, add it to 1L substrate solution, add pyridoxal triphosphate to 100mg / L, seal it, and pass a small amount of nitrogen to maintain positive pressure, 25°C, stir reaction ;

[0019] 4) feed the substrate solution, and control the concentration of catechol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com