Industrial circulating water system for recovering surplus head and a recovery method thereof

A technology of industrial circulating water and recycling method, which is applied in the direction of water supply pipeline system, water supply device, water supply device, etc., can solve the problems of not maximizing the improvement of system operation efficiency, extensive operation mode of circulating water, and low system operation efficiency, etc., to achieve Improve the competitiveness of the industry, promote energy saving and consumption reduction, and improve the efficiency of system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

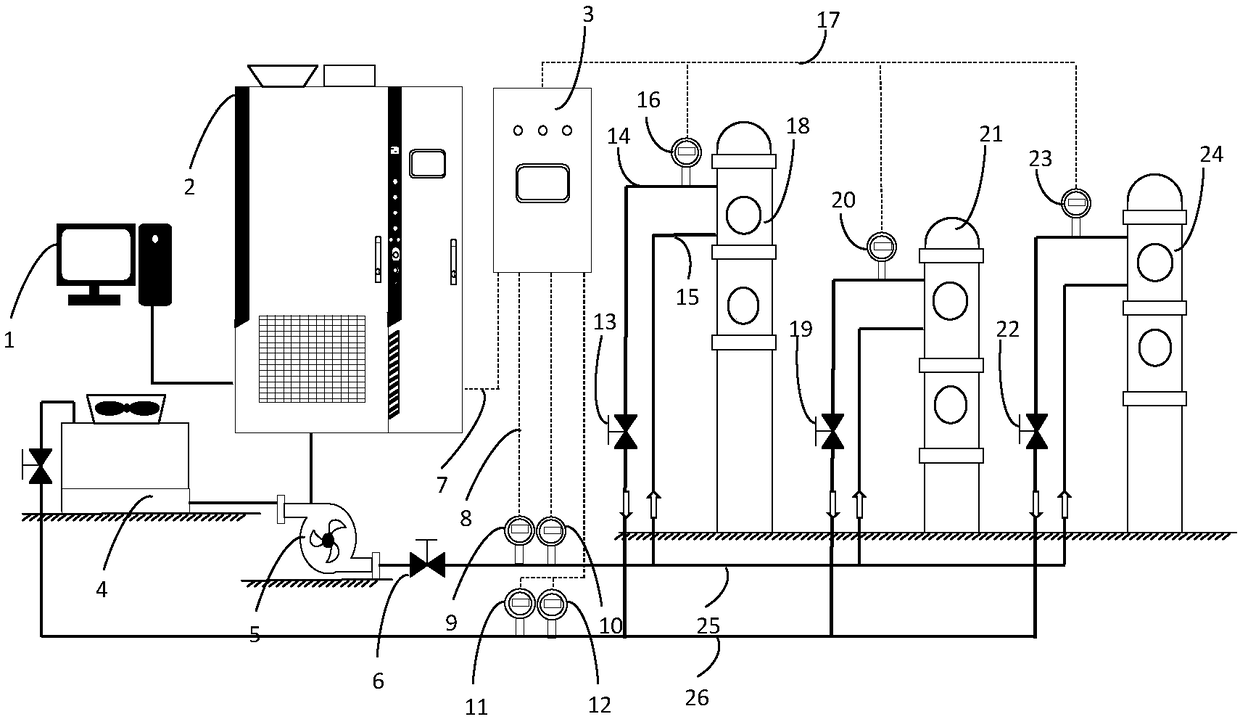

[0053] An industrial circulating water system for recovery of surplus head, including industrial cooling water energy efficiency control management system 1, industrial cooling water energy efficiency control cabinet 2, dual-channel RTU server box 3, cooling tower group 4, cooling pump group 5, pump water outlet Valve 6, total water inlet pressure sensor 9, total water inlet temperature sensor 10, total outlet water pressure sensor 11, total outlet water temperature sensor 12, water inlet branch pipe valve, water inlet branch pipe 14, return water branch pipe 15, negative pressure sensor, rectification The tower device, the main water outlet pipe 25, the main return water pipe 26, the cooling tower group 4 is connected to the water inlet of the cooling pump group 5, the water outlet of the cooling pump group 5 is connected to the water outlet valve 6 of the pump group, and the water outlet valve 6 of the pump group passes through the valve of the water inlet branch pipe It is c...

Embodiment 2

[0060] A method for recovering an industrial circulating water system for recovering excess head, comprising the following steps:

[0061] 1) Each sensor transmits the data obtained in real time to the dual-channel RTU server box;

[0062] 2) There are two RTU servers in the dual-channel RTU server box, and the two RTU servers perform data switching and calculate the signal data of the sensor;

[0063] 3) The dual-channel RTU server box selects the negative pressure data;

[0064] 4) The dual-channel RTU server box transmits the selected negative pressure value to the industrial cooling water energy efficiency control cabinet, and the industrial cooling water energy efficiency control cabinet controls the cooling pump group to recover the excess head.

[0065] Step 2) in, two RTU servers carry out data switching, specifically comprise the following steps:

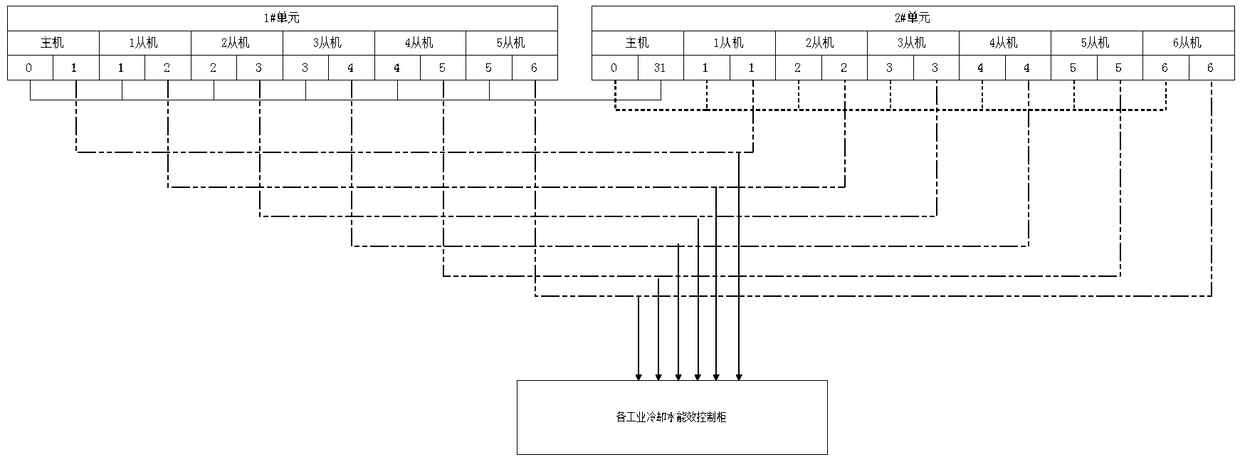

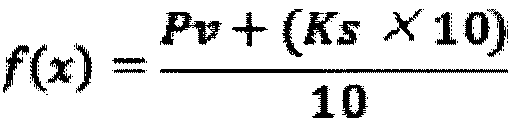

[0066] 1) The 1# unit master reads the data collected by the 1# unit 5 slaves, at this time the 1# unit master contains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com