Thermal power plant black-start power supply and waste heat recycle combined system and application method

A combined system and power supply technology, applied in chemical instruments and methods, steam application, separation methods, etc., can solve the problems of inability to fully utilize low-grade steam, waste energy, pollute the environment, etc., to save fuel consumption and reduce fuel consumption. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

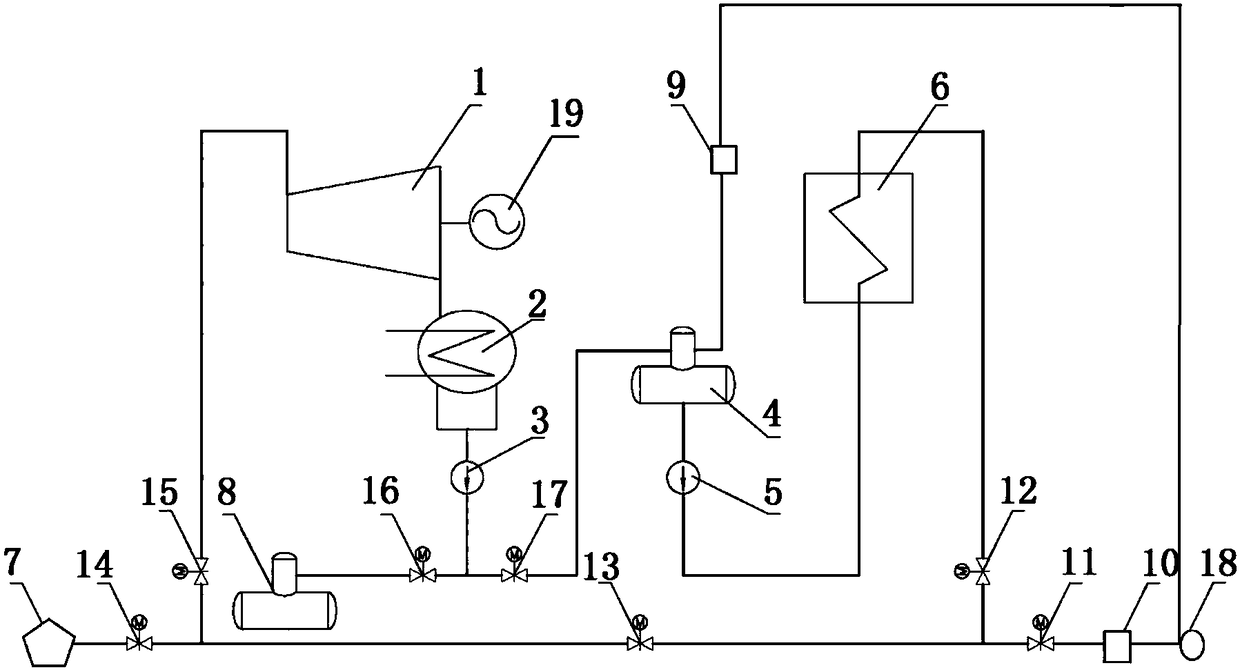

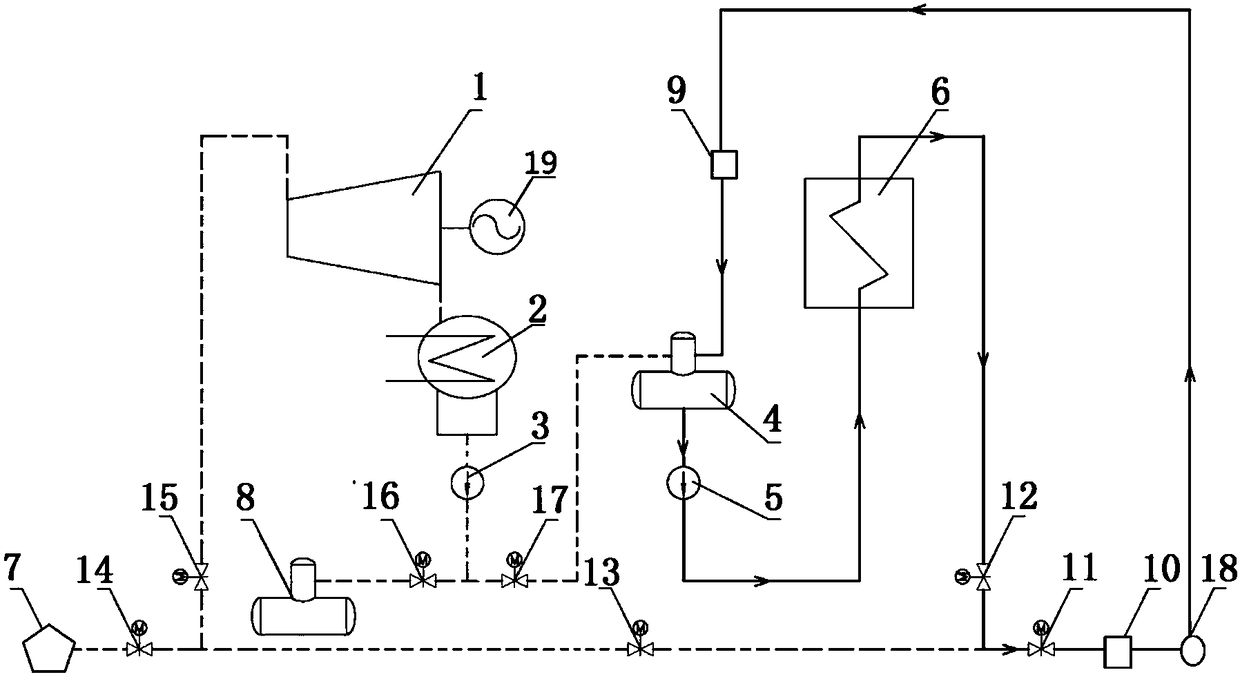

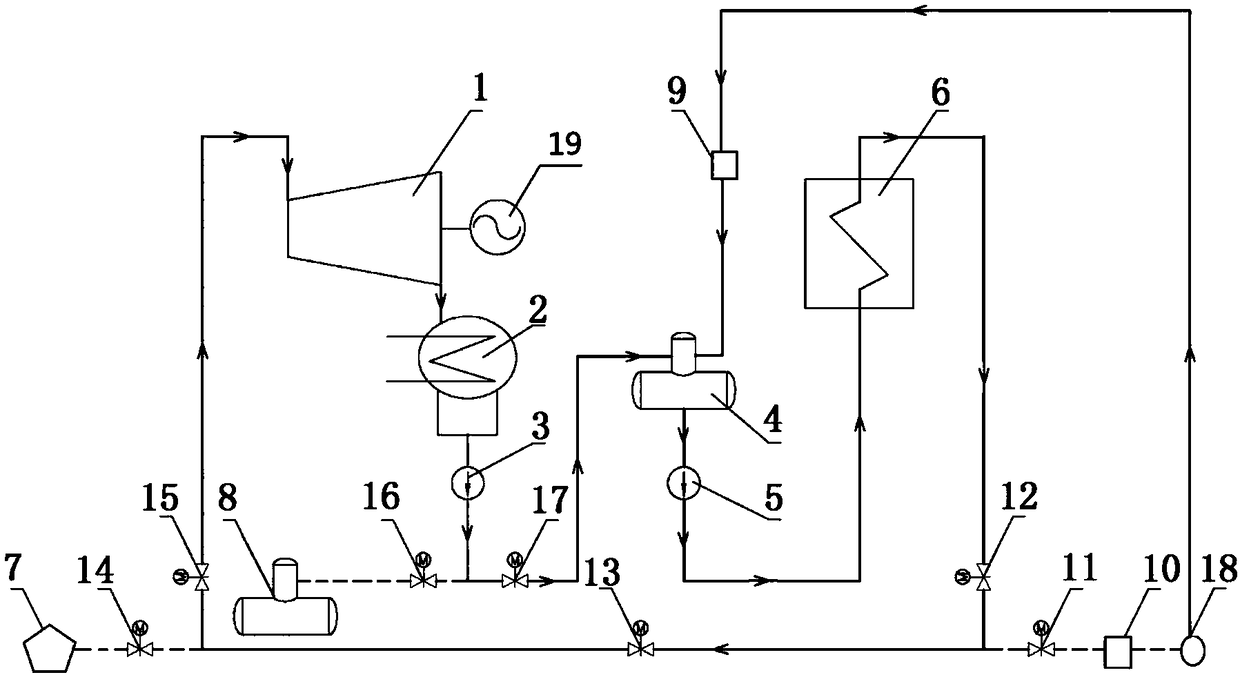

[0047] refer to figure 1 , the thermal power plant black start power supply and waste heat recovery and utilization combined system of the present invention comprises waste heat steam turbine 1, waste heat turbine generator 19, condenser 2, condensate water pump 3, start boiler deaerator 4, start boiler feed water pump 5, Start boiler 6, low-grade steam pipe network 7, thermal power plant deaerator 8, chemical desalination device 9, seawater desalination device 10 and fresh water tank 18.

[0048]There is a control valve B12 on the steam outlet pipe of the start-up boiler 6. After the valve, the steam is divided into two paths. One path is connected to the seawater desalination device 10 through the control valve A11, and the other...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap