Method for integrating garnet film on silicon at low temperature based on transfer printing

A technology for integrating garnets and garnets, which is applied in the field of low-temperature integration of garnet films on silicon based on transfer printing, can solve the problems of high thermal budget and incompatibility with semiconductor processes, and achieve the effect of reducing the degree of corrosion and cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

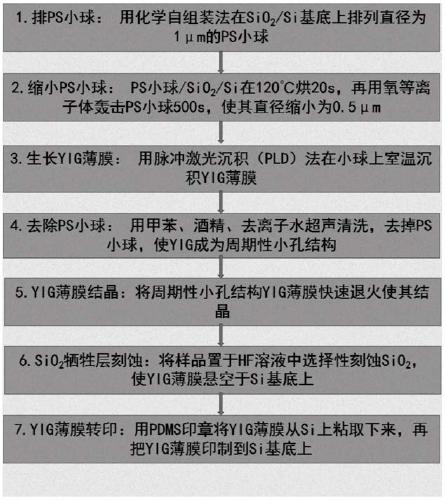

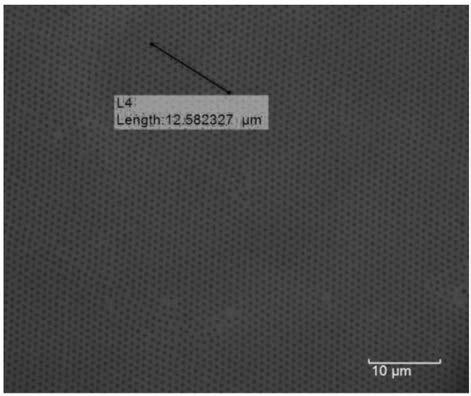

[0025] Step 1: Using chemical self-assembly method on SiO 2 PS spheres with a diameter of 1 μm are arranged in a hexagonal close-packed form on the / Si substrate.

[0026] Step 2: Place the hexagonal close-packed PS pellets in step 1 on a heating plate, heat the PS pellets at 104°C for 20s, and dry the PS pellets; then bombard the pellets in step 2 with oxygen plasma to make the pellets The diameter is reduced to 0.5 μm.

[0027] Step 3: Deposit a YIG film with a thickness of 80 nm at room temperature on the PS pellets finally prepared in Step 2 by pulsed laser deposition (PLD), with a target-base distance of 5.5 cm, a laser frequency of 10 Hz, and an oxygen partial pressure of 0.67 Pa.

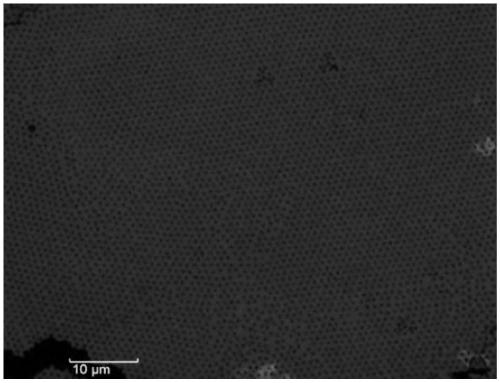

[0028] Step 4: Use toluene, alcohol, and deionized water to ultrasonically clean the sample obtained in step 3 in order to remove the PS pellets, and the SiO 2 / Si substrate to obtain hole structure YIG film.

[0029] Step 5: Place the YIG film with a porous structure obtained in step 4 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com