A method for manufacture a double buffer lay perovskite solar cell

A technology of solar cells and manufacturing methods, which can be applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., and can solve problems such as backward conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

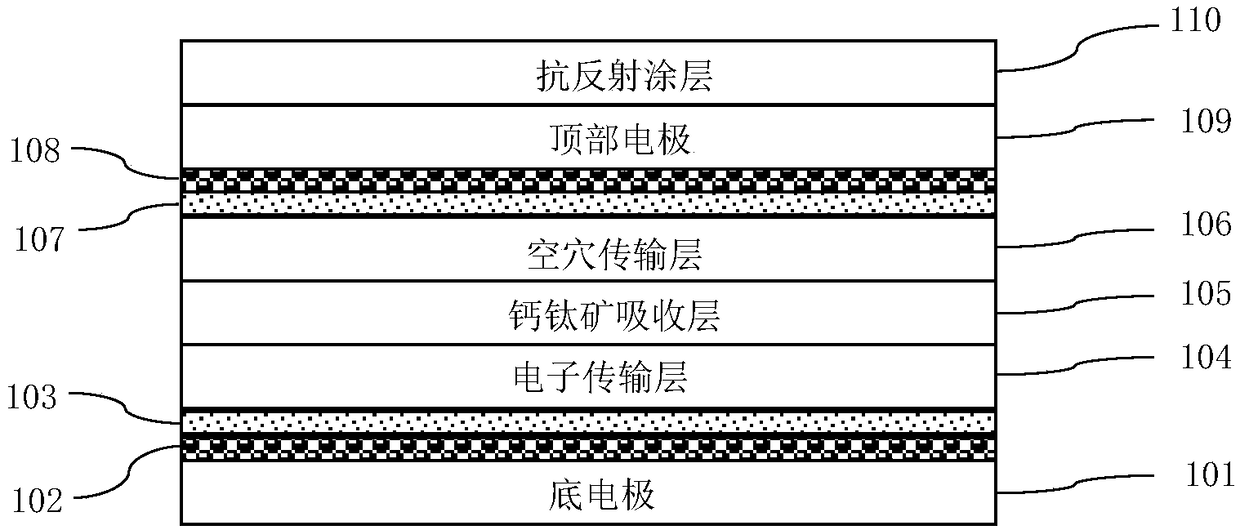

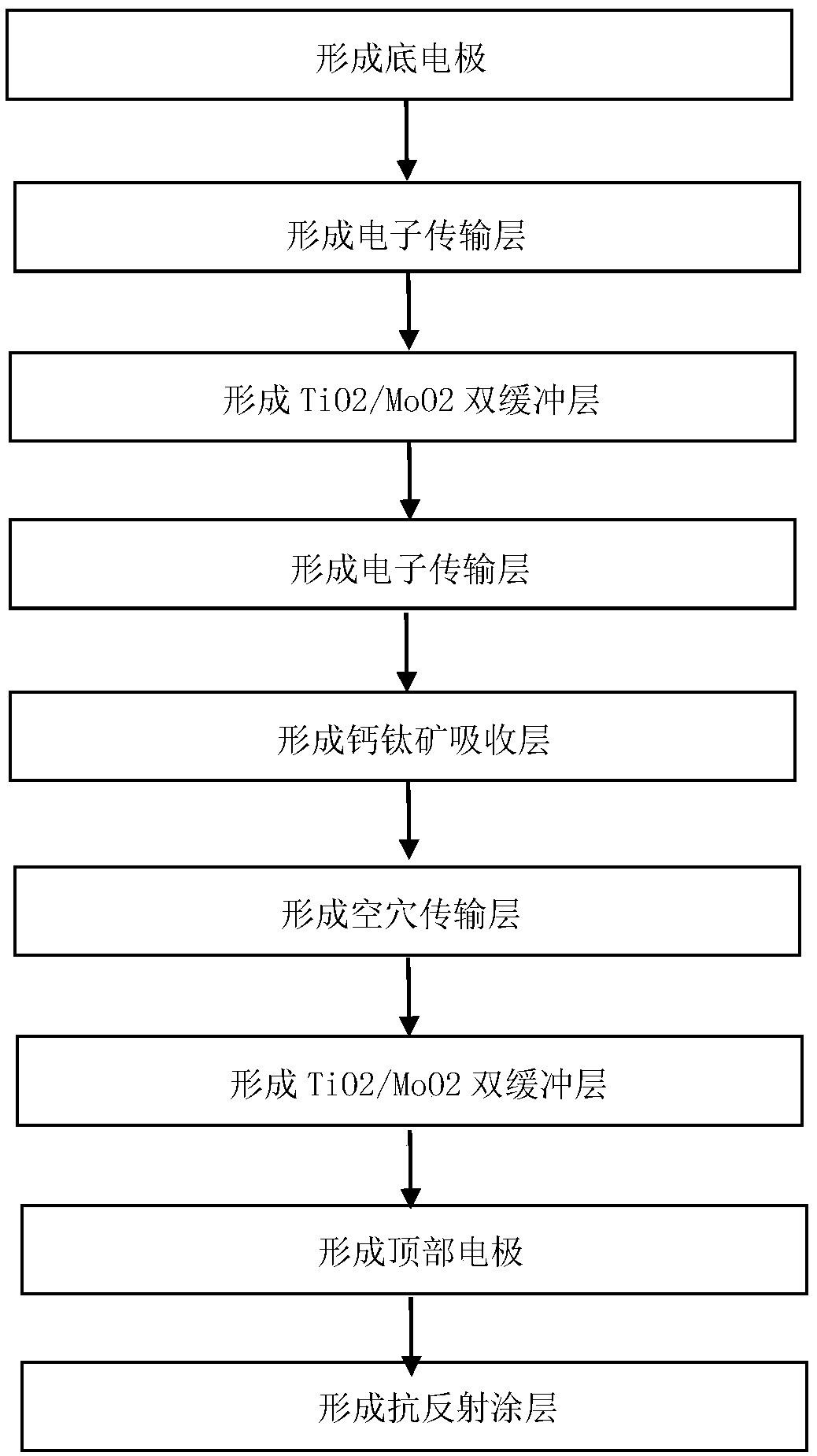

[0028] The FTO transparent conductive glass was ultrasonically cleaned with acetone, ethanol, and deionized water in sequence, and then treated with ultraviolet and ozone to obtain a clean 100 nm transparent conductive glass as the bottom electrode 101 . Use the sol-gel method to spin-coat on the FTO transparent conductive glass substrate to form nano-titanium dioxide particles 102 with a thickness of 20nm, then dry at room temperature to remove excess solvent, and then form a layer of 30nm molybdenum dioxide on it by hydrothermal method layer 103, and slowly raise the temperature to 60°C for drying treatment to form nano-TiO 2 / MoO 2 The buffer layer.

[0029] A layer of TiO electron transport layer 104 with a thickness of 80 nm was formed on the buffer layer, and then a perovskite thin film was spin-coated on the electron transport layer, and the film was placed in a vacuum chamber for 3 seconds to promote perovskite by removing residual solvent. Ore nucleation, spin coati...

Embodiment 2

[0033] The ITO transparent conductive glass was ultrasonically cleaned with acetone, ethanol, and deionized water in sequence, and then treated with ultraviolet and ozone to obtain a clean 100 nm transparent conductive glass as the bottom electrode 101 . Use the sol-gel method to spin-coat on the ITO transparent conductive glass substrate to form nano-titanium dioxide particles 102 with a thickness of 20nm, then dry at room temperature to remove excess solvent, and then form a layer of 30nm molybdenum dioxide on it by hydrothermal method layer 103, and slowly raise the temperature to 60°C for drying treatment to form nano-TiO 2 / MoO 2 The buffer layer.

[0034] A 20nm ZnO electron transport layer 104 is formed on the buffer layer, followed by spin-coating a perovskite thin film on the electron transport layer, and placing the film in a vacuum chamber for 3 seconds to promote the formation of perovskite by removing residual solvent. The core is spin-coated in ambient air; spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com