Intelligent rapid digestion device

A fast and digestive tube technology, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of slow cooling of the furnace body and slow natural cooling of the digestive tube, limiting the digestion rate of the experimental process, The degree of automation is not high, and the temperature in the furnace can be continuously adjusted, the water utilization rate can be improved, and the air cooling efficiency can be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

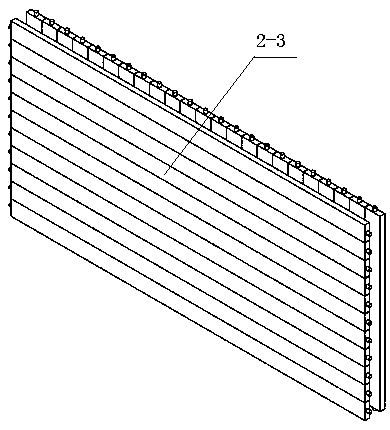

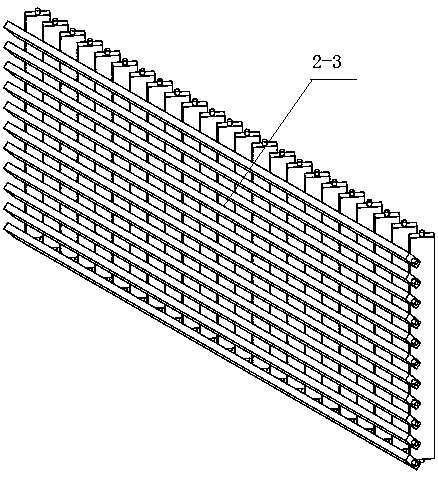

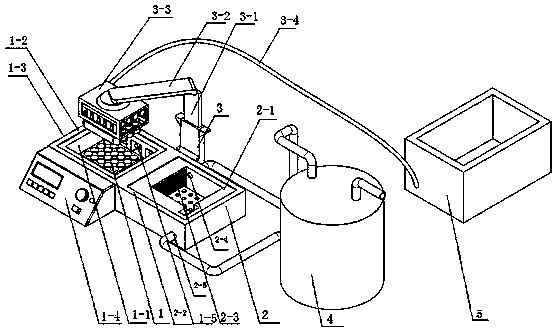

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described: as Figure 1-4 As shown, an intelligent rapid digestion device includes a digestion device 1, a cooling device 2, a lifting device 3, and a cooling water tank 4; it is characterized in that: the digestion device 1 is connected to the cooling device 2; the lifting device 3 is located between the digestion device 1 and the cooling The upper middle of device 2 is fixed on the rear side of digestion device 1;

[0029] The digestion device 1 includes a digestion furnace body 1-1, an air-cooled interlayer 1-2, a casing 1-3, and a control unit 1-4; wherein, the casing 1-3 is wrapped in the outer layer of the digestion furnace body 1-1, and the digestion furnace body A cavity is formed between 1-1 and the shell 1-3, the cavity is the air duct of the air-cooled interlayer 1-2, one end of the air duct is provided with a closed baffle 1-6, and the air outlet at the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com