Denitration catalyst for activated carbon-supported iron-manganese-titanium and preparation method and application thereof

A denitration catalyst, activated carbon technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problem of insufficient activity, and achieve improved stability, good denitration effect and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

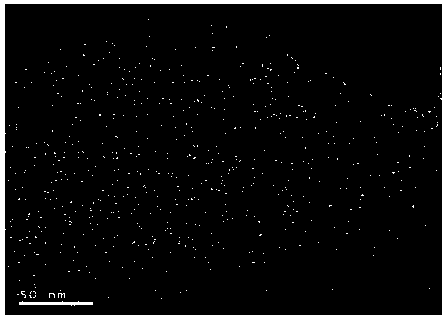

Image

Examples

Embodiment 1

[0032] Weigh 50g of activated carbon, wash it with deionized water, put it into a 100mL beaker filled with 60 mL of water and soak it for 24 hours, stir it every 1 hour, take the activated carbon out of the water and dry it at 80°C 4h, packaged to obtain pretreated activated carbon, and set aside.

[0033] Weigh 71.91 g of potassium permanganate and dissolve it in 20 mL of 95% ethanol to prepare a solution of potassium permanganate in ethanol. Weigh Fe(NO 3 ) 3 9H 2 Dissolve 36.07g of O powder in 60 mL of water to make an aqueous solution of iron salt, stir for 15 minutes, and prepare TiCl with a mass fraction of 18%.4 aqueous solution, weigh the TiCl 4 57.40 mL of the aqueous solution was slowly added dropwise to the aqueous solution of the iron salt at a rate of 1 drop / s, and stirred. After stirring for 45 minutes, the pretreated activated carbon obtained above was added, and ultrasonication was performed. The ultrasonic power was 550W, and ultrasonication was performed f...

Embodiment 2

[0035] Weigh 50g of activated carbon, wash it with deionized water, put it into a 100mL beaker filled with 60mL of water and soak it for 24 hours, stir it every 1 hour, take the activated carbon out of the water and dry it at 80°C for 4 hours , packaged to obtain pretreated activated carbon, and set aside.

[0036] Weigh 71.91 g of potassium permanganate and dissolve it in 20 mL of 95% ethanol solution to prepare an ethanol solution to form potassium permanganate. Weigh Fe(NO 3 ) 3 9H 2 Dissolve 36.07 g of O powder in 60 mL of water to make an aqueous solution of iron salt, stir for 15 min, and prepare Ti(C 4 h 9 O) 4 aqueous solution, weigh the Ti(C 4 h 9 O) 4 177.76 mL of aqueous solution was slowly added dropwise to the aqueous solution of iron salt at a rate of 1 drop / s. After stirring for 45 minutes, the pretreated activated carbon obtained above was added, and ultrasonication was performed. The ultrasonic power was 550W. After ultrasonication for 30 minutes, the ...

Embodiment 3

[0038] Weigh 75g of activated carbon, wash it with deionized water, put it into a 100mL beaker filled with 90 mL of water and soak it for 24 h, stir it every 1 h, take the activated carbon out of the water and dry it at 80°C 4h, packaged to obtain pretreated activated carbon, and set aside.

[0039] Weigh 107.87 g of potassium permanganate and dissolve it in 30 mL of 95% ethanol solution to prepare an ethanol solution to form potassium permanganate. Weigh Fe(NO 3 ) 3 9H 2 Dissolve 54.11g of O powder in 90mL of water to make an aqueous solution of iron salt, stir for 15min, and prepare TiCl with a mass fraction of 18%. 4 aqueous solution, weigh the TiCl 4 86.1 mL of aqueous solution was slowly added dropwise into the aqueous solution of iron salt at a rate of 1 drop / s. After stirring for 45 minutes, the pretreated activated carbon obtained above was added, and ultrasonication was performed. The ultrasonic power was 550W. After ultrasonication for 30 minutes, the The above-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com