Iron-doped bimetal phosphide electrocatalyst and preparation method and application thereof

A phosphide electro-bimetallic technology is applied in the field of electrocatalysis to achieve the effect of increasing the specific surface area, strong repeatability and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

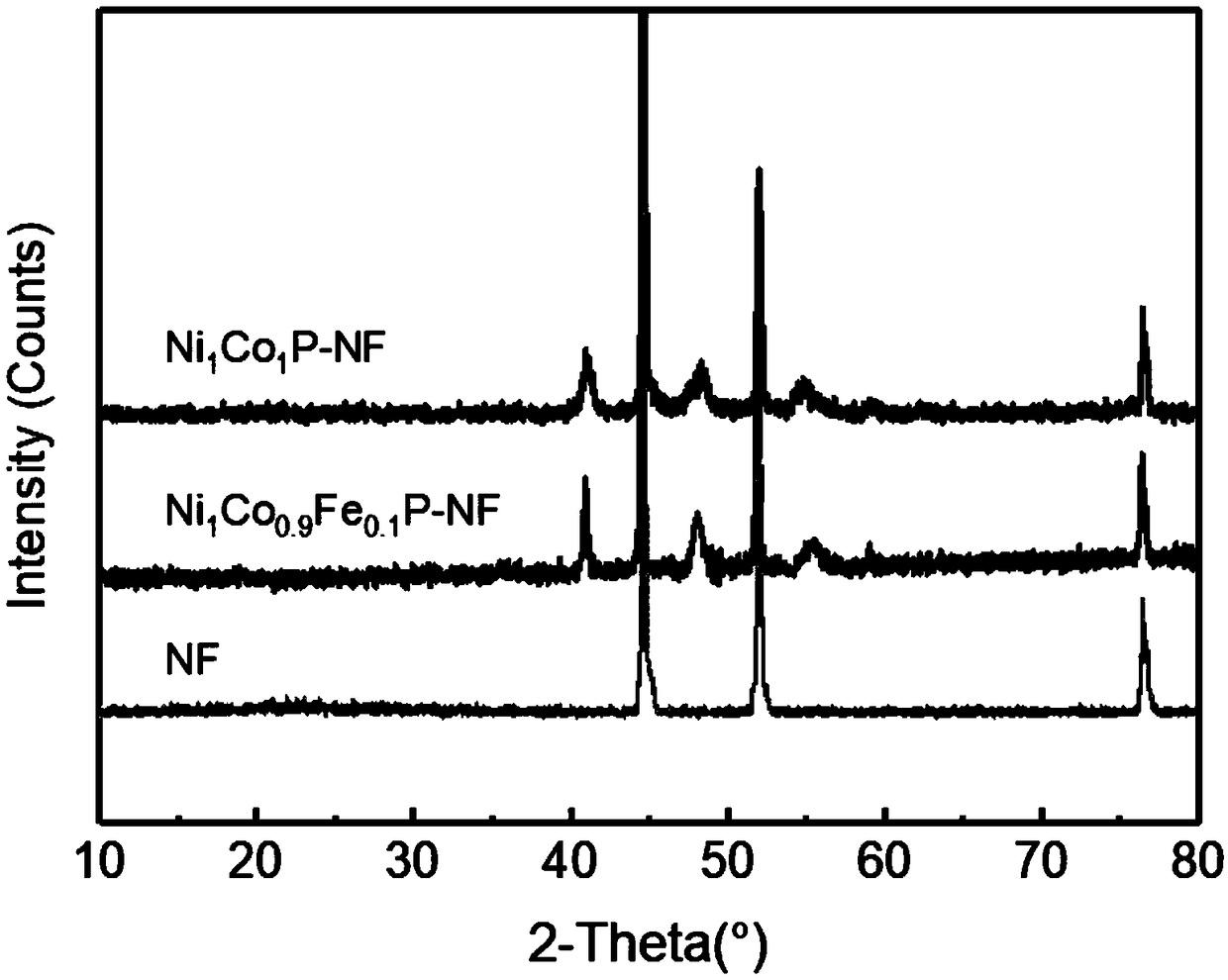

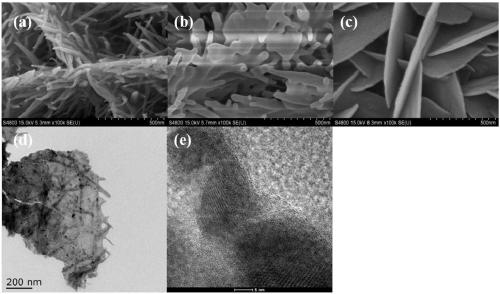

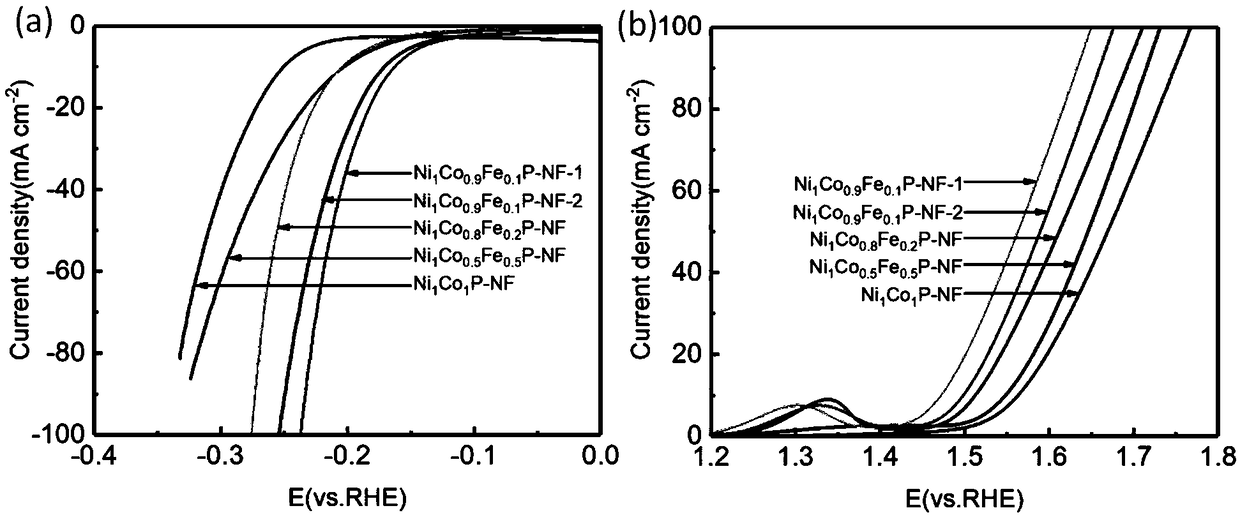

[0026] Iron-doped nickel-cobalt-phosphorus bimetallic phosphide (Ni 1 co 0.8 Fe 0.2 Preparation of P-NF):

[0027] The nickel foam was ultrasonically cleaned with 3M hydrochloric acid, deionized water, acetone and ethanol in sequence for 30 minutes, and then dried at 60°C for 12 hours.

[0028] Weigh 0.582g Ni(NO 3 ) 2 ·6H 2 O, 0.4656g Co(NO 3 ) 2 ·6H 2 O, 0.1616g Fe(NO 3 ) 3 9H 2 O, 0.592NH 4 F and 1.2g urea were added to 80mL deionized water and stirred for 30 minutes to obtain precursor solution A (Ni:Co=1:0.8); put 2×5 (cm) foamed nickel into precursor solution A, transfer Into a 100mL reactor, hydrothermally reacted at 90°C for 9h to obtain the reddish-brown product Ni 1 co 0.8 Fe 0.2 -Pre-NF: Take out the nickel foam, wash with water and alcohol, and dry at 60°C for 12 hours.

[0029] Weigh NaH 2 PO 2 Placed in a crucible, located upstream of the nitrogen gas flow, the Ni produced above 1 co 0.8 Fe 0.2 -Pre-NF is placed in the crucible, located downs...

Embodiment 2

[0031] The preparation method of this electrocatalytic material is basically the same as Example 1, the difference is: change Co(NO 3 ) 2 ·6H 2 The amount of O added makes Ni:Co=1:1, without adding Fe(NO 3 ) 3 9H 2 O, the material is named Ni 1 co 1 P-NF.

Embodiment 3

[0033] The preparation method of this electrocatalytic material is basically the same as that of Example 1, the difference is: Co(NO 3 ) 2 ·6H 2 The mass of O is 0.291g, Fe(NO 3 ) 3 9H 2 The mass of O is 0.404 g (Ni:Co:Fe=1:0.5:0.5). The material is named Ni 1 co 0.5 Fe 0.5 P-NF.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com