Impurity removal system for removing silt and sugarcane leaves in sugar refinery

A sugarcane leaf and sediment technology, applied in the direction of application, separating solids from solids with airflow, solid separation, etc., can solve the problems of reducing sugar recovery, increasing content, sugar production equipment, technology, and recovery effects, etc. Achieve the effect of improving sugar quality and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

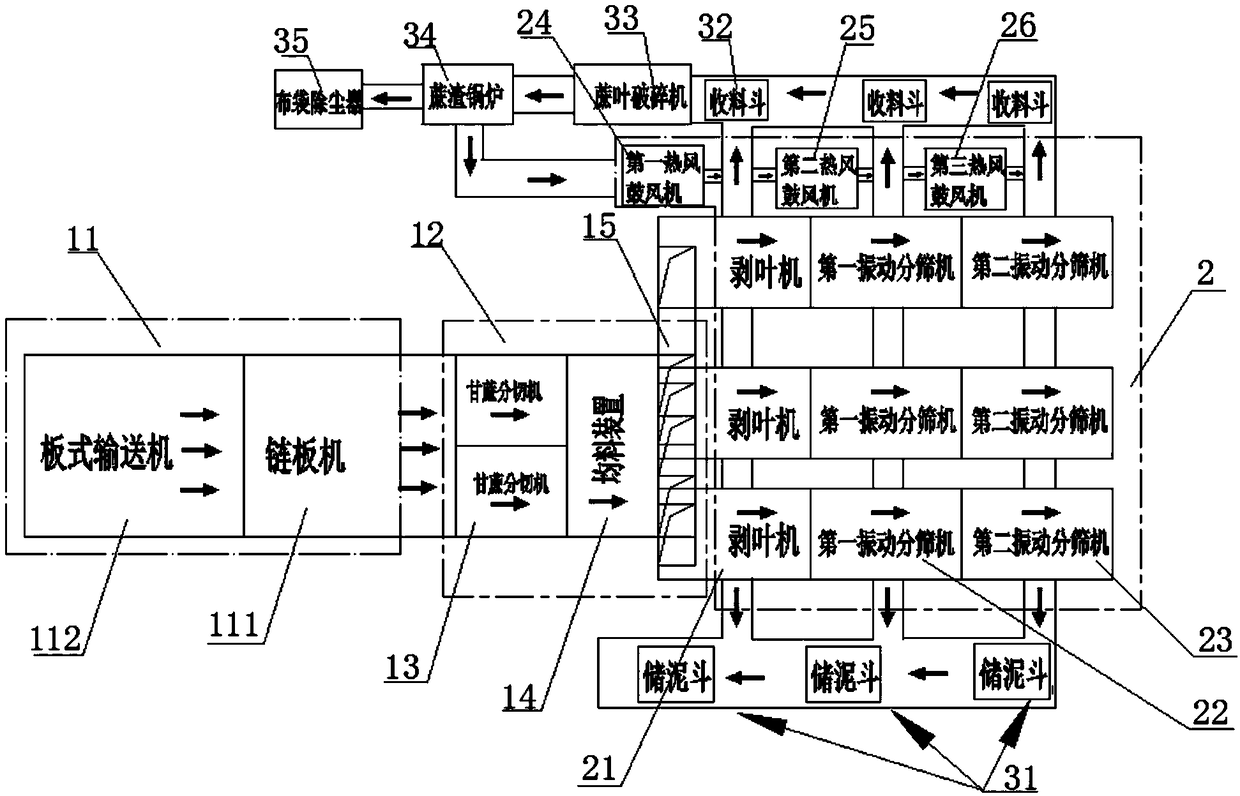

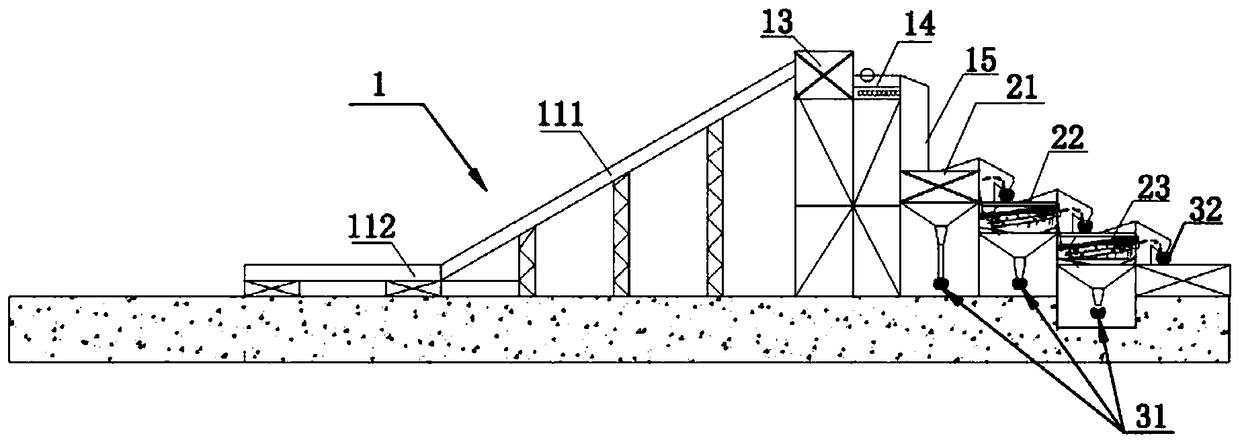

[0024] A system for removing impurities from silt and sugarcane leaves, which includes a body 1; the body 1 includes a slitting pretreatment station 12 for cutting raw cane, and is used to transport raw cane to sugarcane slitting pretreatment The feeding station 11 of the station 12, the impurity removal and sorting station 2 for removing impurities from the cut raw cane, and the waste recycling station for reclaiming sugarcane leaves;

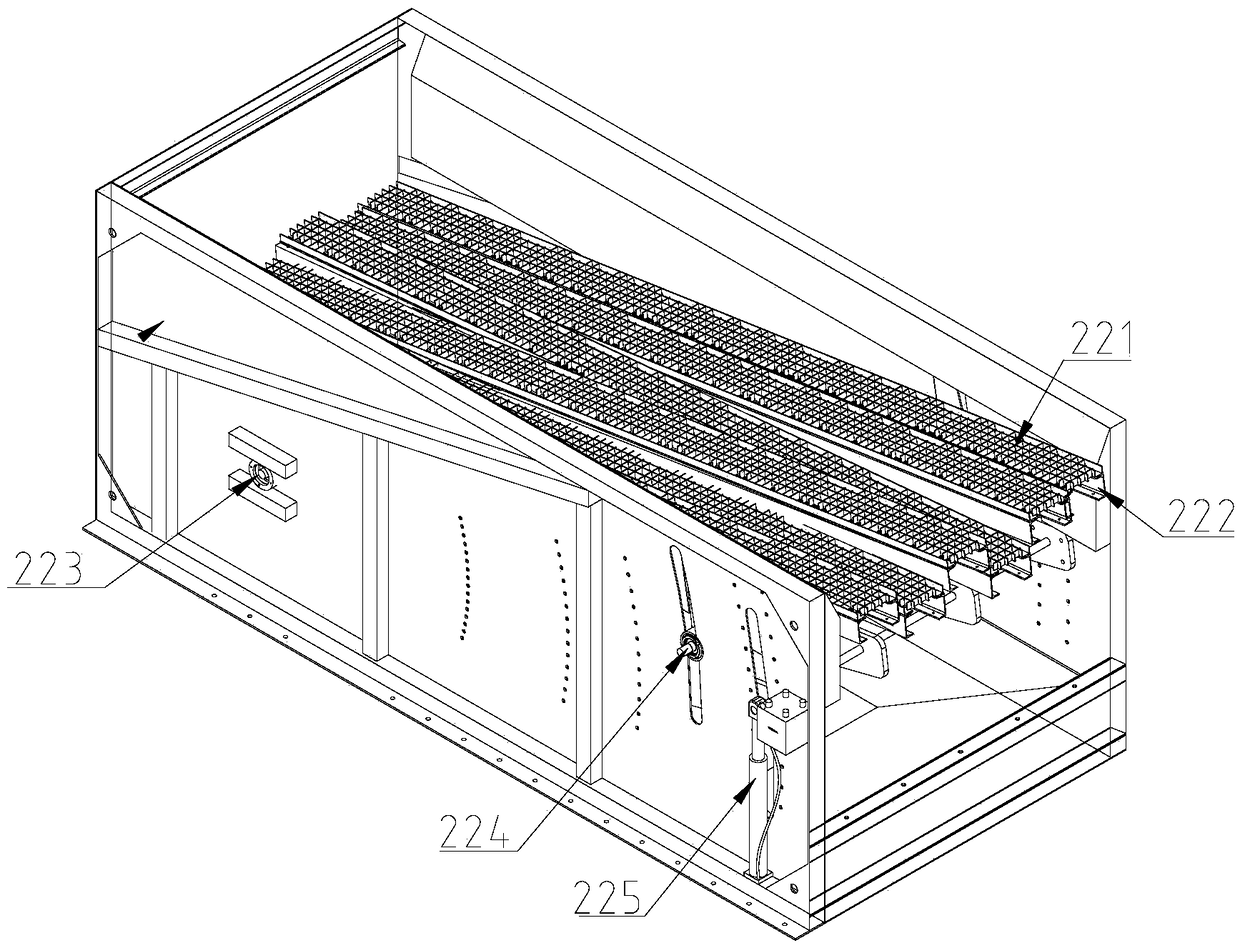

[0025] The impurity-removing and sorting station 2 includes a leaf stripper 21 for stripping the cut raw cane leaves, a vibrating screener for removing sediment from the stripped raw cane;

[0026] Described vibration sorting machine comprises the first vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com