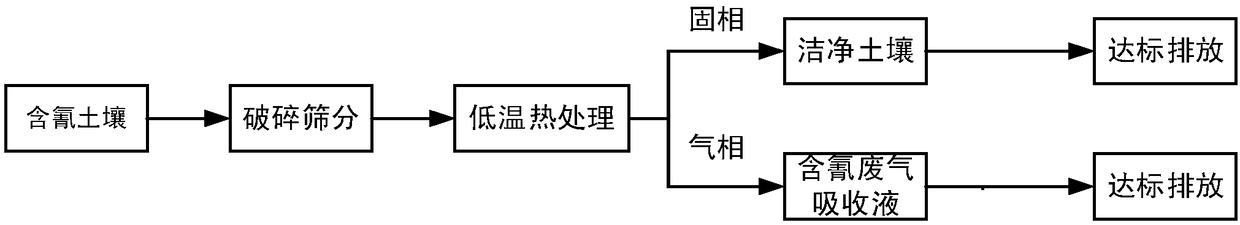

Method for restoring cyanide contaminated soil by using low-temperature heat treatment technology

A technology for low-temperature heat treatment and polluted soil, applied in the field of soil remediation, can solve the problems of complicated operation, low cyanide removal rate, high energy consumption, and achieve the effect of high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

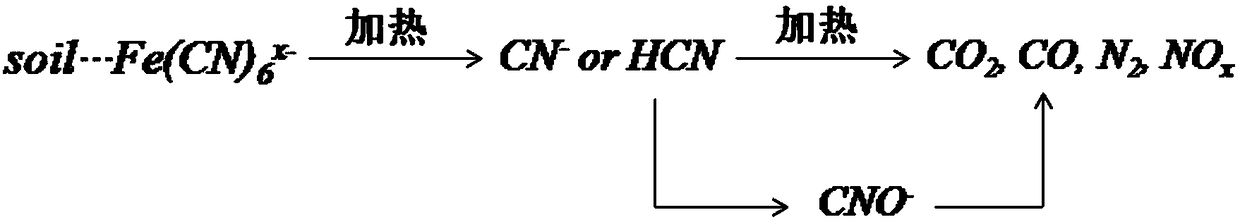

Method used

Image

Examples

Embodiment 1

[0036] Use potassium ferricyanide mold to mix soil A-1 for experiments (theoretical value of cyanide content is 100mg / kg, measured value is 86.72±1.04423mg / kg), crushed to a particle size below 2mm and sieved, then take 12g of A-1 after sieving The sample is placed in a tube furnace, and then heated at 250°C for 1 hour to decompose potassium ferricyanide, and then the tail gas generated by thermal decomposition is passed into the sodium hydroxide absorption solution with a pH of 12 through a closed pipeline.

Embodiment 2

[0038] Use potassium ferricyanide mold to mix soil A-2 for experiment (theoretical value of cyanide content is 1000mg / kg, measured value is 1007±9.0367mg / kg), crush to particle size below 2mm and sieve, then take 12g A-2 after sieving The sample is placed in a tube furnace, and then heated at 250°C for 1 hour to decompose potassium ferricyanide, and then the tail gas generated by thermal decomposition is passed into the sodium hydroxide absorption solution with a pH of 12 through a closed pipeline.

Embodiment 3

[0040] Potassium ferrocyanide was used to mix soil B-1 for experiments (theoretical value of cyanide content was 100mg / kg, measured value was 73.85±2.0367mg / kg), crushed to a particle size below 2mm and sieved, and then 12g of B- 1 Place the sample in a tube furnace, and then heat it at 250°C for 1 hour to decompose potassium ferricyanide, and then pass the tail gas generated by thermal decomposition into the sodium hydroxide absorption solution with a pH of 12 through a closed pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com