Laser welding method capable of refining aluminum alloy weld joint structure

A technology of laser welding and aluminum alloy, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of limited welding product size and structural form, unsatisfactory effect, poor applicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weld the LF6 aluminum alloy butt joint structure.

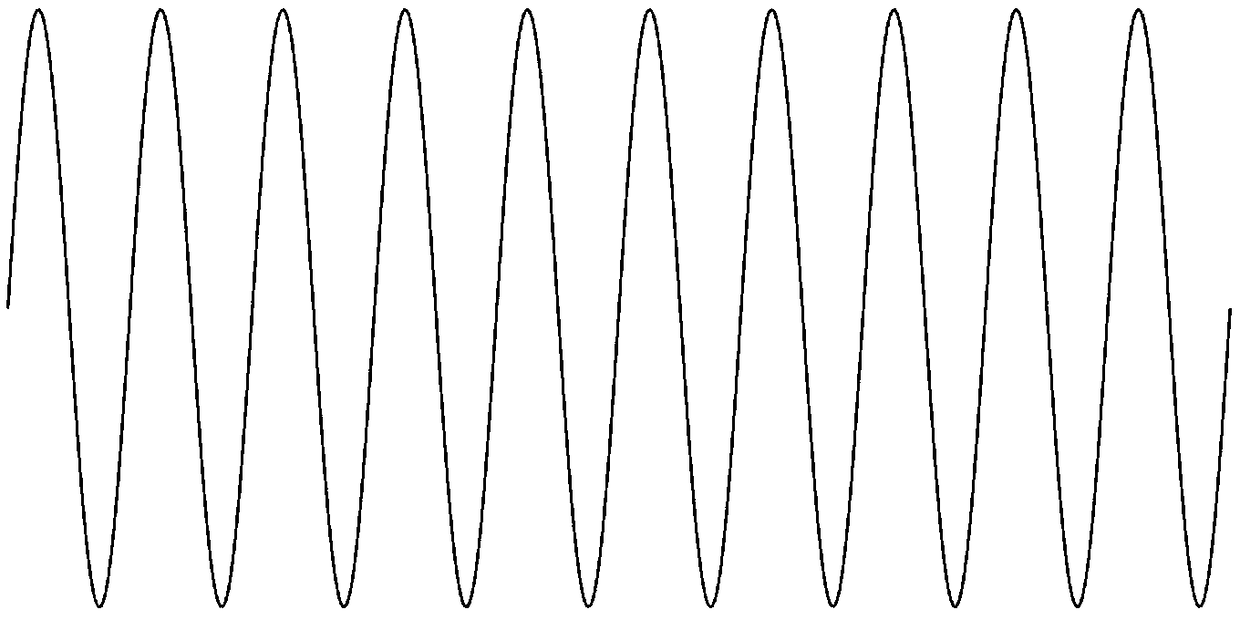

[0023] Before laser welding, clean up the scale, oil and other impurities within the range of (20-50) mm from the center of the weld; during welding, the swing path of the laser beam is a sinusoidal path, such as figure 1 As shown, the swing amplitude H is 2 mm, the swing frequency is 300 Hz, and other welding process parameters are the same as conventional laser welding process parameters.

[0024] The results show that: the central structure of conventional laser welding seam of 5A06 aluminum alloy is equiaxed crystal and coarse dendrite, and there are still more dendrites in the central structure of sinusoidal laser swing welding seam, but it is more dense than that of conventional laser welding seam. A certain degree of refinement.

Embodiment 2

[0026] Weld the LF6 aluminum alloy butt joint structure.

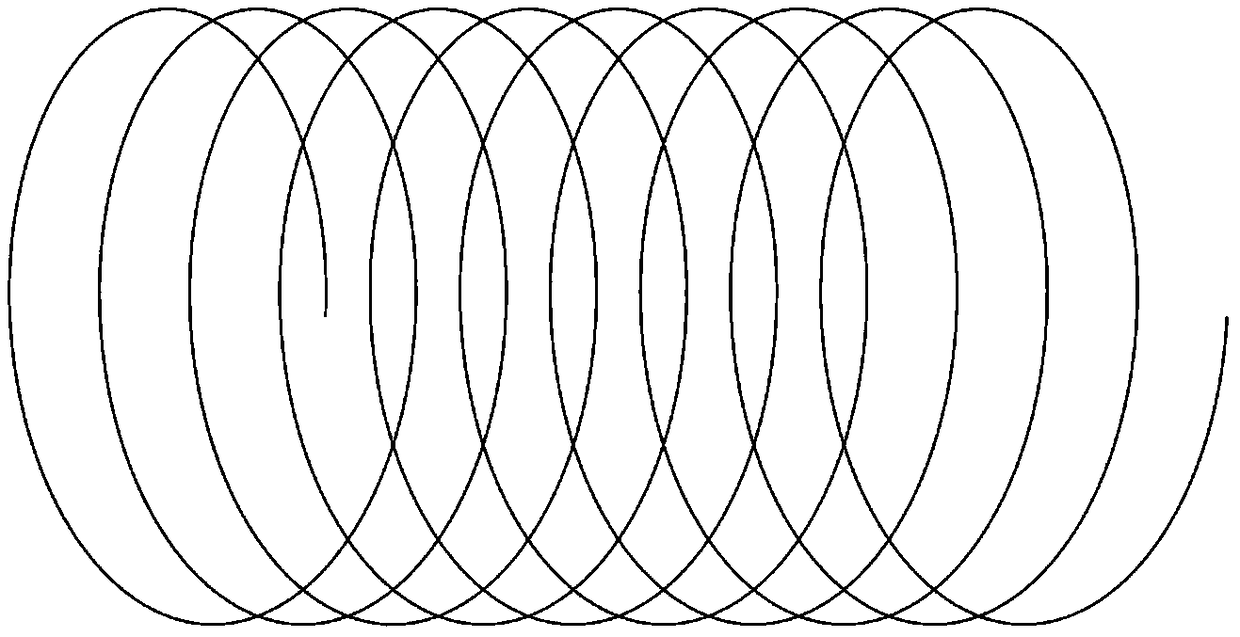

[0027] Before laser welding, clean up the scale, oil and other impurities within the range of (20-50) mm from the center of the weld; during welding, the swing path of the laser beam is a spiral path, such as figure 2 As shown, the swing amplitude H is 2 mm, the swing frequency is 300 Hz, and other welding process parameters are the same as conventional laser welding process parameters.

[0028] The results show that the central microstructure of 5A06 aluminum alloy conventional laser welding seam is equiaxed crystal and coarse dendrite, while the central microstructure of helical laser swing welding seam still has dendrite structure, which is finer than that of conventional laser welding seam central microstructure.

Embodiment 3

[0030] Weld the LF6 aluminum alloy butt joint structure.

[0031] Weld the LF6 aluminum alloy butt joint structure.

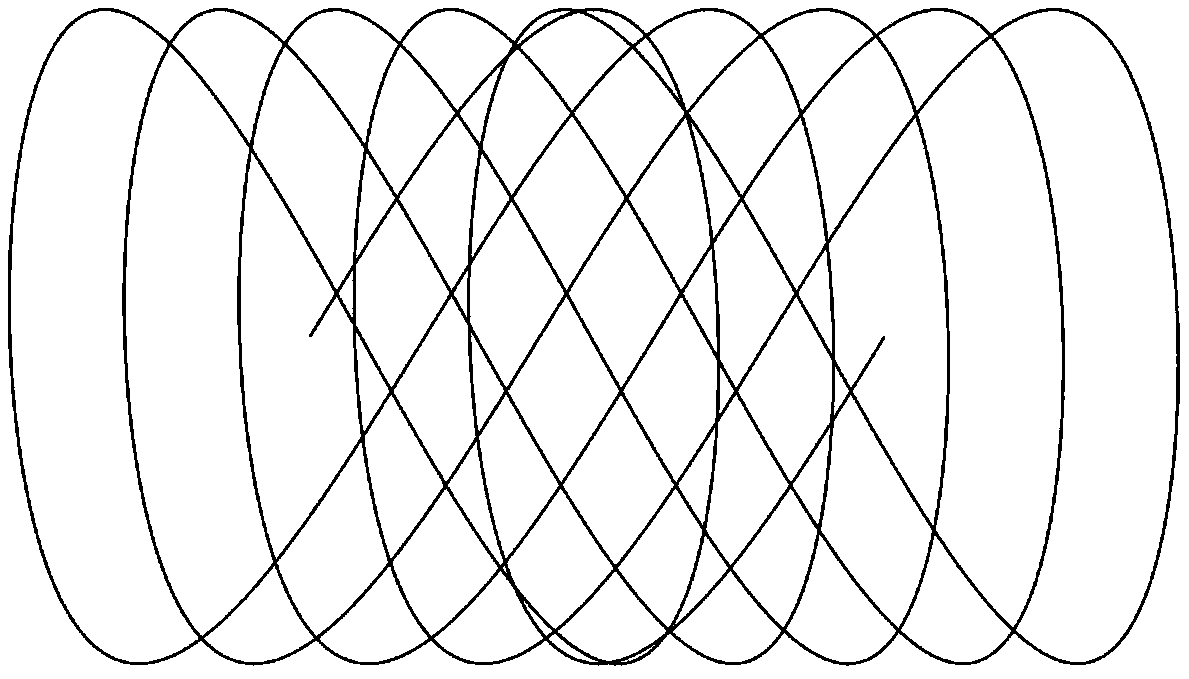

[0032] Before laser welding, clean up the scale, oil and other impurities within the range of (20-50) mm from the center of the weld; during welding, the swing path of the laser beam is a double-helix path, such as image 3 As shown, the swing amplitude H is 2 mm, the swing frequency is 300 Hz, and other welding process parameters are the same as conventional laser welding process parameters.

[0033] The results show that: the central structure of conventional laser welding seam of 5A06 aluminum alloy is equiaxed crystal and coarse dendrite, and the central structure of double helix laser swing welding seam is all equiaxed crystal without dendrite structure. Noticeable refinement of central tissue occurs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com