Manufacturing method of hollow ceramic membrane

A technology for hollow ceramics and a manufacturing method, which is applied in the direction of ceramic molding cores, ceramic molding machines, ceramic molding mandrels, etc., which can solve the problems of low equipment requirements and narrow adjustment range of membrane apertures, and achieve low equipment requirements and reduce gluing processes , The effect of short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] Preparation of slurry: Weigh the raw materials of paraffin wax, plastic reinforcing agent and filler in the formula, heat and melt and stir to make a slurry with good fluidity; wherein, the inner mold core is prepared from paraffin wax, plastic reinforcing agent and filler The mass ratio of the paraffin wax, plastic reinforcing agent and filler is (5-24):(1-3):1. The plastic reinforcing agent is one or a mixture of two or more of PP, HDPE, PET, PBT, and PS; the filler is one or a mixture of two or more of graphite, wood chips, and walnut sand.

[0051] The step of crushing: placing the cooled solid of the above-mentioned slurry in a crusher to crush into particles of uniform thickness; the particle size of the particles ranges from 2 to 4 mm;

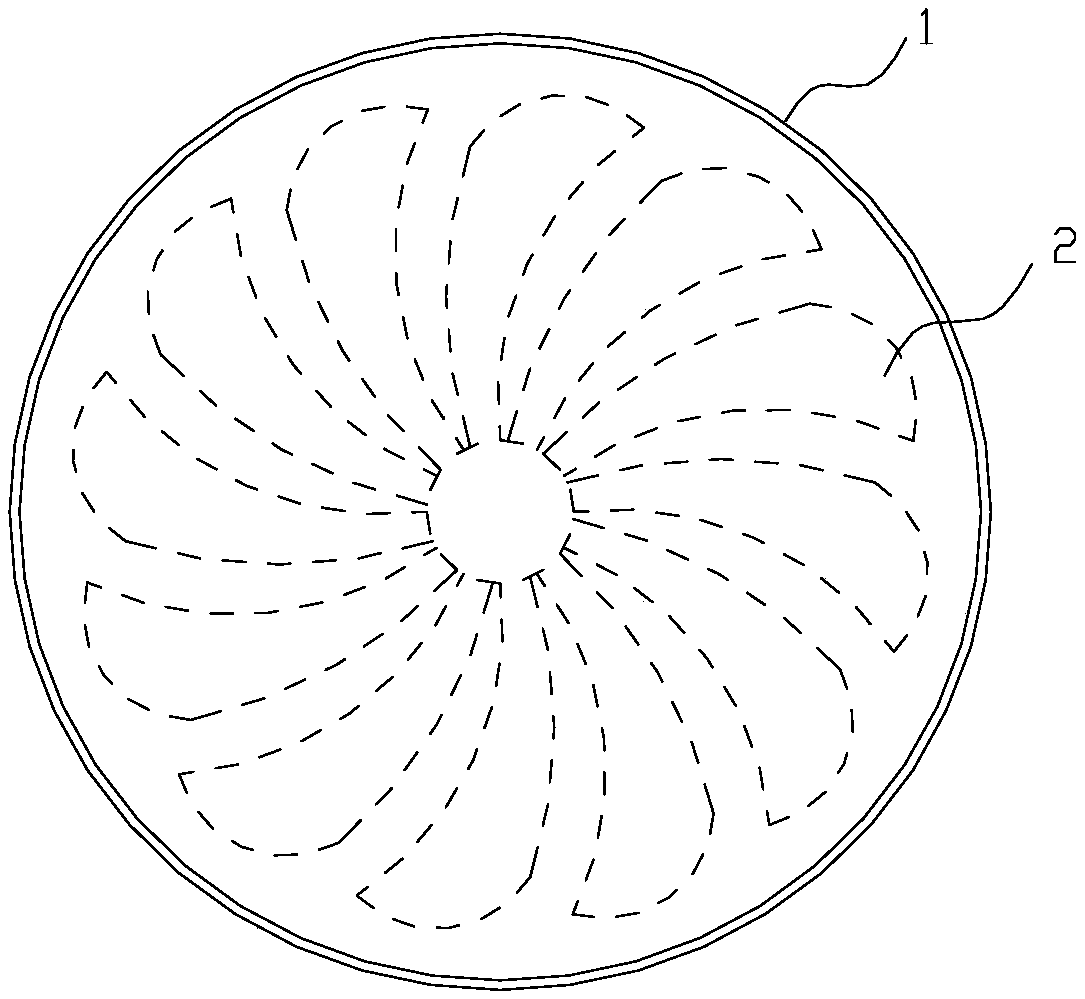

[0052] Injection molding steps: use an injection molding machine to inject and mold an inner mold core of the desired shape. As a further embodiment, the desired shape includes one or a combination of regular shapes such as cyli...

Embodiment 1

[0058] Example 1: Inner Model Core

[0059] The making of inner model core comprises the following steps:

[0060] 1. Preparation of slurry: Weigh 2400g of paraffin, 150g of PP, and 150g of HDPE, and add them together into a heatable mixer. Set the temperature at 180°C and start stirring. As the temperature rises, the paraffin, PP, and HDPE melt slowly. After melting, add 300g of graphite powder and stir together for 30 minutes, then pour into the tray and cool to room temperature naturally;

[0061] 2. The step of crushing: take out the cooled solid and put it in a crusher to crush it into small particles with uniform particles; the particle size range of the particles is 2-4mm;

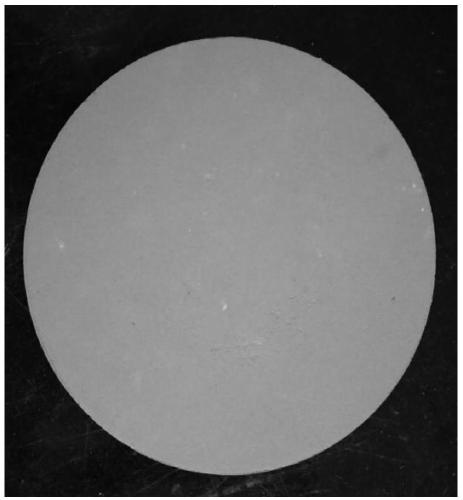

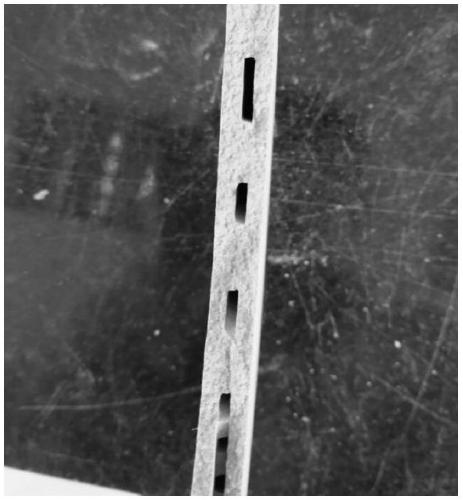

[0062] 3. Injection molding steps: adjust the temperature and injection pressure of the injection molding machine, and inject a turbo-shaped core, such as figure 1 shown.

Embodiment 2

[0063] Embodiment 2 semi-dry ceramic powder

[0064] The making of semi-dry ceramic powder comprises the following steps:

[0065] 1. The steps of ball milling: Weigh 2400g of 200-mesh alumina aggregate, 600g of 1 micron alumina aggregate, fine-grained alumina aggregate as a strengthening agent for coarse-grained alumina aggregate, 90g of HPMC with a viscosity of 100,000, industrial Titanium dioxide 15g is put into the ball mill together and dry ball milled for 4 hours to make prefabricated powder;

[0066] 2. Stirring steps: Take out the prefabricated powder and add it to a mixer that can spray water, spray 300g of clean water and stir for 10 minutes while stirring, then spray 15g of vegetable oil and stir for 30 minutes, then take out the powder;

[0067] 3. Stale steps: the powder is sealed and stale for 24 hours; the above-mentioned stale powder is passed through a 20-mesh sieve, and the sieved part is the prepared semi-dry pressed powder. The moisture content of the cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com