A kind of preparation method of pvc-gel mesh electric driver

A driver and net-like technology, applied in the direction of processing and manufacturing, manufacturing tools, additive manufacturing, etc., to achieve the effect of rapid prototyping and high strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of a kind of PVC-gel mesh electric drive of the present invention comprises the following steps:

[0033] 1) Configuration of printing ink: polyvinyl chloride (PVC), butylene adipate (DBA) and tetrahydrofuran (THF) are used as raw materials; according to polyvinyl chloride (PVC), butylene adipate (DBA) Mix at a certain mass ratio, then dissolve in tetrahydrofuran, stir and mix evenly until PVC is evenly dispersed in the mixed solution into a milky solution, and then stand for 1-2 hours until the bubbles are eliminated. In the entire printing ink, seal the bottle cap with a sealing film Seal to prevent the solution from evaporating. Among them, the ratio of PVC to butylene adipate (DBA) can vary from (1:1 to 1:5); the ratio of (PVC+DBA) to tetrahydrofuran is 1: (2-3). After mixing, it becomes a shear-thinning solution.

[0034] 2) Solution and setting of direct write printing parameters

[0035] ①Put the printing ink into the dispensing head equ...

Embodiment 1

[0040] 1) Configuration of printing ink:

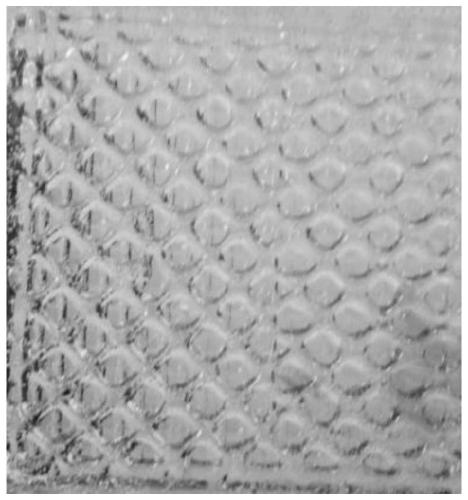

[0041] Such as figure 1 As shown, first weigh 2g of PVC-gel powder and 8g of butylene adipate and mix them, then add 25g of THF, and use magnetic stirring until the PVC powder is fully dissolved in THF, test the rheological properties of the solution, and ensure that the concentration of the ink is suitable Direct write printing.

[0042] 2) Direct write printing process

[0043] ①Put the printing ink into the dispensing head equipped with a needle, and install the dispensing needle on the three-axis mobile platform, use the syringe pump to control the extrusion flow of the ink to 0.03ml / min, and use the 3D printing software to control the scanning speed to 36mm / s, the height of the nozzle from the forming plate is 0.5mm, and the setting temperature of the forming plate is 50°C;

[0044] ②Set the scanning distance to 0.15mm, and conduct the line-to-surface experiment to obtain a relatively flat single-layer PVC-gel layer, and the t...

Embodiment 2

[0049] 1) Configuration of printing ink:

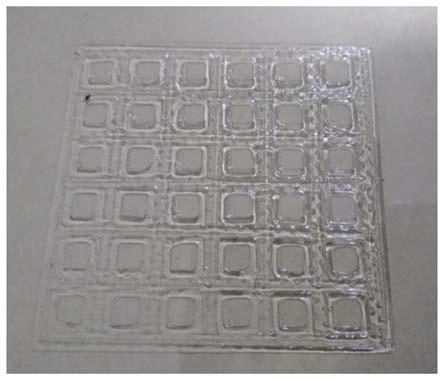

[0050] Such as figure 2 As shown, first weigh 2.5g of PVC-gel powder and 8g of butylene adipate and mix them, then add 30g of THF, use magnetic stirring until the PVC powder is fully dissolved in THF, test the rheological properties of the solution, and ensure the concentration of the ink Suitable for direct writing printing.

[0051] 2) Direct write printing process

[0052] ①Put the printing ink into the dispensing head equipped with a needle, and install the dispensing needle on the three-axis mobile platform, use the syringe pump to control the extrusion flow rate of the ink to 0.05ml / min, and use the 3D printing software to control the scanning speed to 30mm / s, the height of the nozzle from the forming plate is 0.2mm, and the setting temperature of the forming plate is 40°C;

[0053] ②Set the scanning distance to 0.12mm, and conduct the line-to-surface test to obtain a relatively flat single-layer PVC-gel layer, and the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com