Method used for preparing layered double metal hydroxides through mechanical ball milling

A layered bimetallic and hydroxide technology, applied in the direction of oxygen/ozone/oxide/hydroxide, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of poor crystallinity of products and achieve good crystallinity and purity High, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Take 0.7624g MgCl 2 •6H 2 O with 0.3018g AlCl 3 •6H 2 O is placed in the ball mill tank of a planetary ball mill, dripped with 7mL of ammonia water, put in 85g of grinding balls, and ball milled at a speed of 470r / min for 2.5h, take out the slurry obtained after ball milling, add 20mL of distilled water and place it in a beaker for 30min of ultrasonication, and let it stand After precipitation for 20 minutes, discard the supernatant, then add 20 mL of distilled water, sonicate 5 times (add 5 mL of distilled water for the last time), centrifuge, and vacuum-dry the sample at 120°C until the sample has constant weight, and grind to obtain a nano-Mg-Al LDH sample.

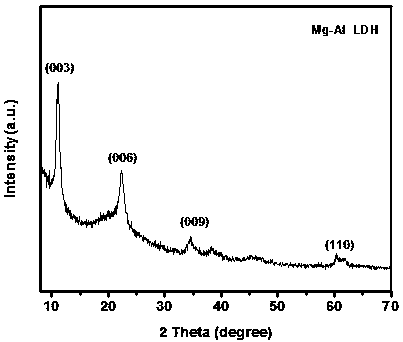

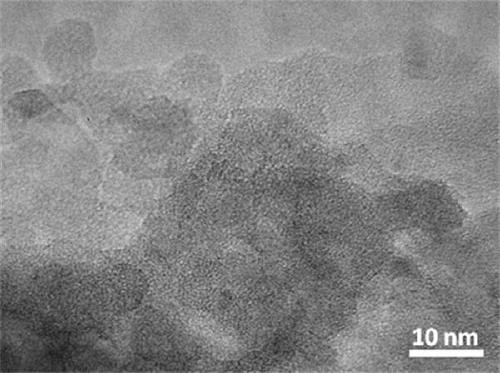

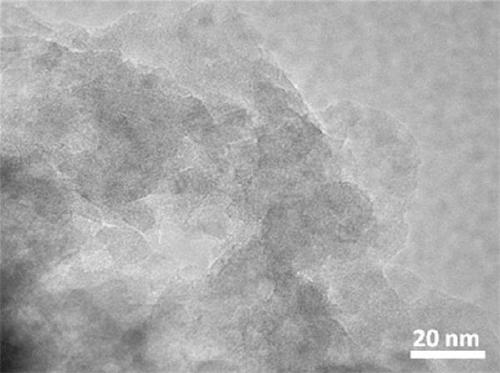

[0014] figure 1 It is the X-ray powder diffraction pattern of the Mg-Al LDH sample prepared in Example 1, and the diffraction peaks are symmetrical sharp peaks, indicating good crystallinity. Comparing the standard XRD pattern of Mg-Al LDH, it can be seen that the peak positions of the prepared Mg-Al LDH and...

Embodiment 2

[0017] Take 0.7624g MgCl 2 •6H 2 O with 0.3018g AlCl 3 •6H 2 O is placed in the ball mill tank of a planetary ball mill, dripped with 14mL of ammonia water, put in 85g of grinding balls, and ball milled at a speed of 470r / min for 2.5h, take out the slurry obtained after ball milling, add 20mL of distilled water and place it in a beaker for ultrasonication for 30min, and let it stand After precipitation for 20 minutes, discard the supernatant, then add 20 mL of distilled water, sonicate 5 times (add 5 mL of distilled water for the last time), centrifuge, and vacuum-dry the sample at 120°C until the sample has constant weight, and grind to obtain a nano-Mg-Al LDH sample.

Embodiment 3

[0019] Take 0.7624g MgCl 2 •6H 2 O with 0.3018g AlCl 3 •6H 2O is placed in the ball mill tank of a planetary ball mill, dripped with 6mL of ammonia water, put in 85g ball mill balls, and milled at a speed of 470r / min for 2h. During the milling period, add 3mL of ammonia water dropwise every 30min, and finish dripping twice. After taking out the ball mill Add 20mL of distilled water to the obtained slurry and put it in a beaker for ultrasonication for 30min, let it settle for 20min, pour off the supernatant, then add 20mL of distilled water, ultrasonicate for 5 times in total (add 5mL of distilled water for ultrasonication at the last time), centrifuge, and place in a vacuum at 120°C Dry the sample to a constant weight, and grind to prepare a nano-Mg-Al LDH sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com