Method for removing gallium from low-gallium Bayer process mother liquor

A technology with Bayer method and low concentration, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, purification of aluminate/alumina/aluminum hydroxide, etc., which can solve the problem that the purity of alumina cannot meet the requirements of high-purity production The requirements of aluminum, the difficulty of removing other metal impurities, and the large energy consumption of the evaporation and concentration process have achieved the effects of avoiding high liquid viscosity, reducing the dissolution rate, and preventing resin poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

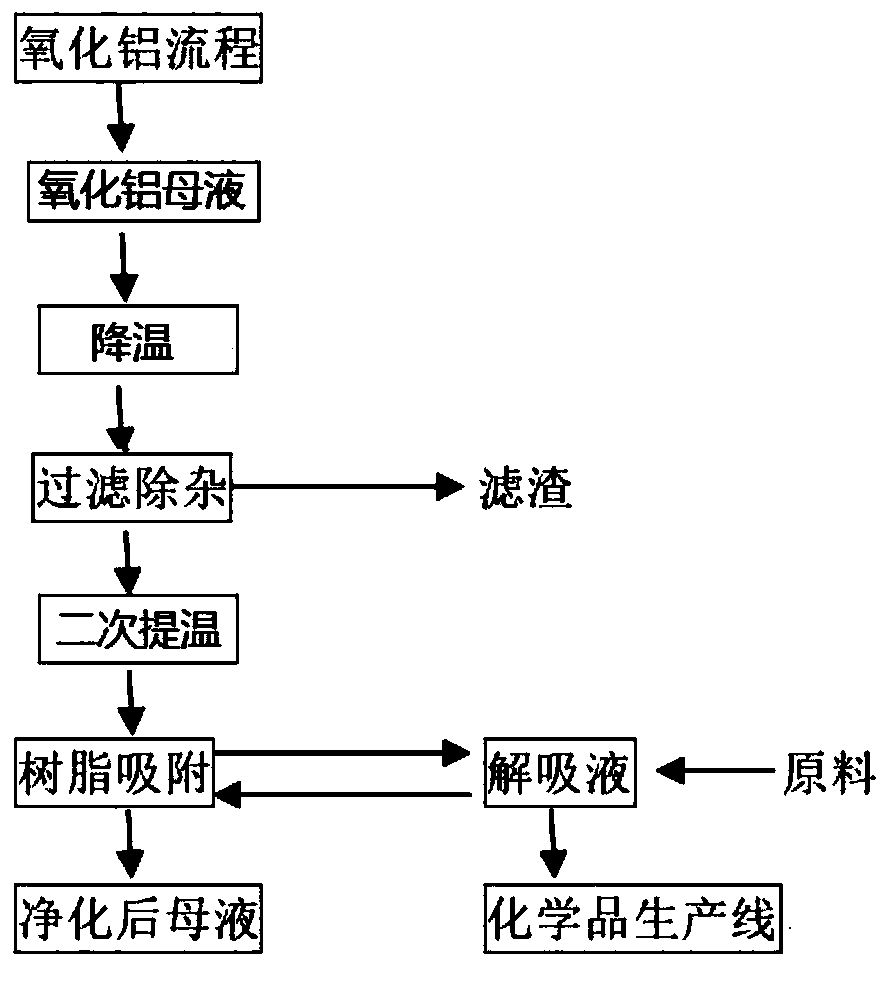

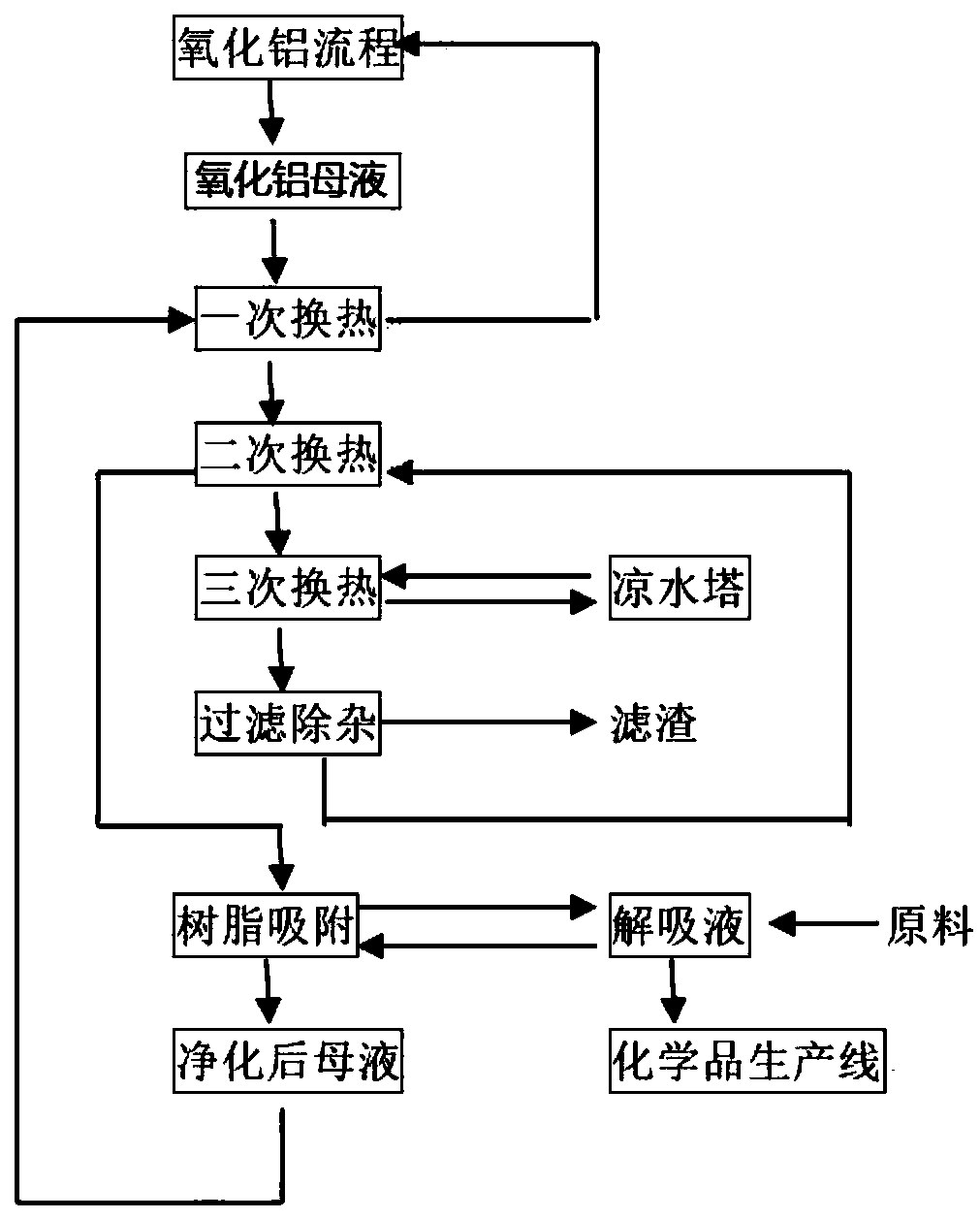

[0028] This embodiment provides a method for removing gallium from the Bayer process mother liquor with low gallium concentration, and its process flow chart is as attached figure 1 As shown, the process steps include:

[0029] 1) Use the low-temperature Bayer process to dissolve bauxite to reduce the dissolution rate of metal gallium in the ore. The dissolution temperature is 140°C, and then use concentrated sodium hydroxide solution to convert aluminum hydroxide into sodium aluminate. By diluting and adding The aluminum hydroxide seeds cause the aluminum hydroxide to re-precipitate, and the solution after the aluminum hydroxide is collected is the alumina mother liquor, and the temperature of the alumina mother liquor is lower than 70°C.

[0030] 2) Cooling and impurity removal: The alumina mother liquor obtained in step (1) is subjected to cooling treatment. The initial temperature of the alumina mother liquor is 68° C., and the temperature of the alumina mother liquor afte...

Embodiment 2

[0035] This embodiment provides a method for removing gallium from the Bayer process mother liquor with low gallium concentration, and its process flow chart is as attached figure 1 As shown, the process steps include:

[0036] 1) Use the low-temperature Bayer process to dissolve bauxite to reduce the dissolution rate of metal gallium in the ore. The dissolution temperature is 130°C, and then use concentrated sodium hydroxide solution to convert aluminum hydroxide into sodium aluminate. By diluting and adding The aluminum hydroxide seeds cause the aluminum hydroxide to re-precipitate, and the solution after the aluminum hydroxide is collected is the alumina mother liquor, and the temperature of the alumina mother liquor is lower than 70°C.

[0037] 2) Cooling and removing impurities: the alumina mother liquor obtained in step (1) is subjected to cooling treatment, the initial temperature of the alumina mother liquor is 60°C, and the temperature of the alumina mother liquor aft...

Embodiment 3

[0042] This embodiment provides a method for removing gallium from the Bayer process mother liquor with low gallium concentration, and its process flow chart is as attached figure 1 As shown, the process steps include:

[0043] 1) Use the low-temperature Bayer process to dissolve bauxite to reduce the dissolution rate of metal gallium in the ore. The dissolution temperature is 135°C, and then use concentrated sodium hydroxide solution to convert aluminum hydroxide into sodium aluminate. By diluting and adding The aluminum hydroxide seeds cause the aluminum hydroxide to re-precipitate, and the solution after the aluminum hydroxide is collected is the alumina mother liquor, and the temperature of the alumina mother liquor is lower than 70°C.

[0044] 2) Cooling and removing impurities: the alumina mother liquor obtained in step (1) is subjected to cooling treatment. The initial temperature of the alumina mother liquor is 67° C., and the temperature of the alumina mother liquor a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com