High-energy storage density barium strontium titanate-based leadless relaxor ferroelectric ceramic and preparation method thereof

A technology of ferroelectric ceramics and barium strontium titanate, which is applied in the field of functional ceramics, can solve the problems of low energy storage density and bulky energy storage devices, and achieve high energy storage density, high energy storage efficiency, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

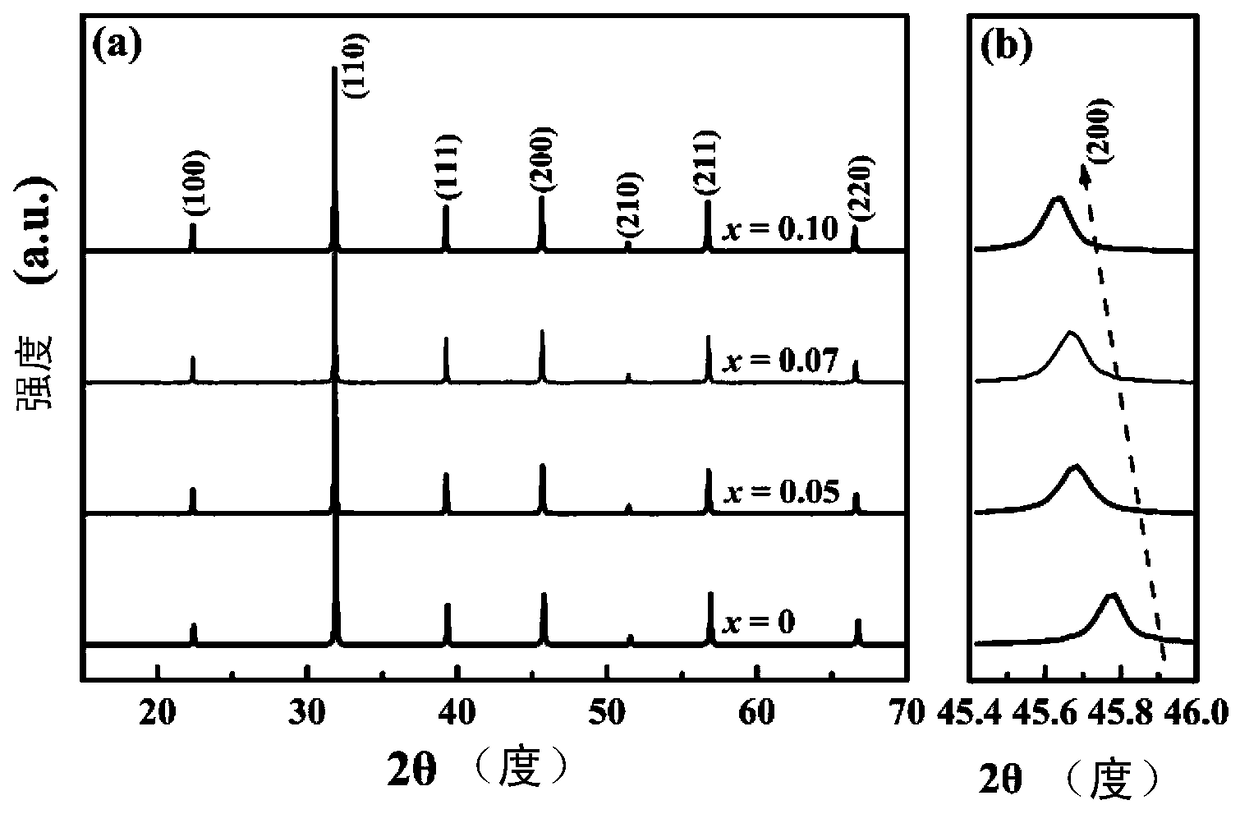

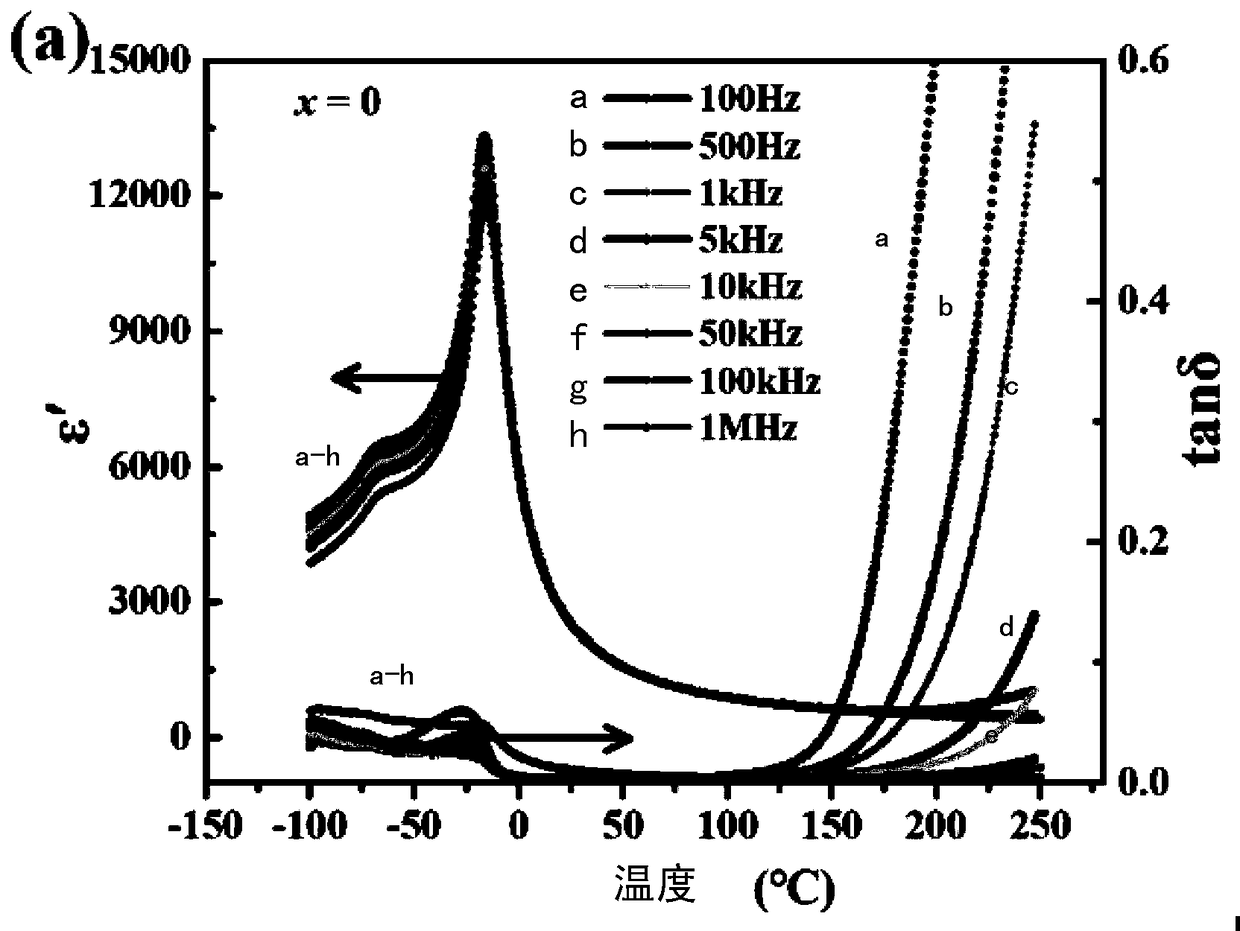

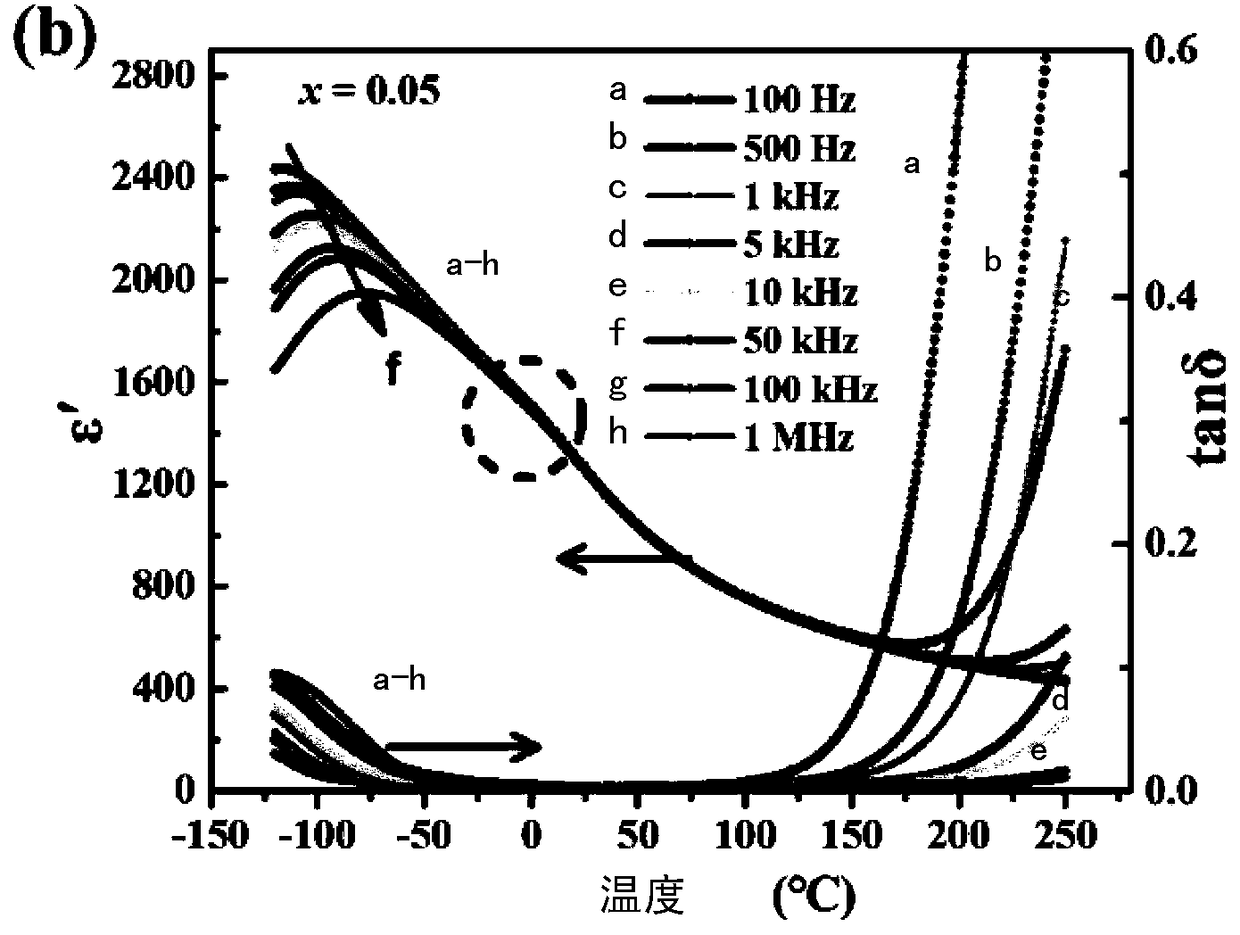

[0030] The invention relates to a lead-free relaxor ferroelectric ceramic based on strontium barium titanate with high energy storage density and a preparation method thereof. The composition of ceramic material of the present invention is: (1-x) (Ba 0.55 Sr 0.45 )TiO 3 -xBi(Mg 2 / 3 Nb 1 / 3 )O 3 , wherein, 03 and SrTiO 3 , or BaCO 3 , SrCO 3 and TiO 2 ) press (Ba 0.55 Sr 0.45 )TiO 3 Stoichiometric proportioning, drying and briquetting, synthesis at 1100-1200°C for 2-6 hours to obtain BST ceramic powder; Bi source, Mg source, Nb source (such as Bi 2 o 3 , MgO, Nb 2 o 5 ) and BST ceramic powder according to (1-x)(Ba 0.55 Sr 0.45 )TiO 3 -xBi(Mg 2 / 3 Nb 1 / 3 )O 3 (03 , the energy storage efficiency can be more than 80%, compared with (Ba 0.55 Sr 0.45 )TiO 3 Compared with ceramics, the effective energy storage density is increased by 2.85J / cm 3 , the improvement rate is as high as 167.6%, and the energy storage efficiency is increased by 25.1%. here. "Effectiv...

Embodiment 1

[0050] The composition of the material is

[0051] 0.95 (Ba 0.55 Sr 0.45 )TiO 3 -0.05Bi(Mg 2 / 3 Nb 1 / 3 )O 3

[0052] (1) with BaTiO 3 , SrTiO 3 Powder as raw material, according to (Ba 0.55 Sr 0.45 )TiO 3 Stoichiometric ratio preparation, mixed by wet ball milling, according to the mass ratio ball milling of raw materials: ball: deionized water=1:4.5:1.7 and ball milling for 24 hours, after drying, cross 40 mesh sieves, press large pieces under 5MPa pressure, Rise to 1150°C at a heating rate of 2°C / min, keep the temperature for 4 hours, and synthesize (Ba 0.55 Sr 0.45 )TiO 3 Powder;

[0053] (2) Grind the powder obtained in step (1), pass through a 40-mesh sieve, and then mix with Bi 2 o 3 , MgO, Nb 2 o 5 and other raw materials according to 0.95 (Ba 0.55 Sr 0.45 )TiO 3 -0.05Bi(Mg 2 / 3 Nb 1 / 3 )O 3 Stoichiometric ratio preparation, according to the mass ratio of raw materials: balls: deionized water = 1:5:1.55, mixed for 24 hours, after drying, passed thro...

Embodiment 2

[0060] The composition of the material is

[0061] 0.93 (Ba 0.55 Sr 0.45 )TiO 3 -0.07Bi(Mg 2 / 3 Nb 1 / 3 )O 3

[0062] (1) with BaTiO 3 , SrTiO 3 Powder as raw material, according to (Ba 0.55 Sr 0.45 )TiO 3 Stoichiometric ratio preparation, mixed by wet ball milling, according to the mass ratio ball milling of raw materials: ball: deionized water=1:4.5:1.7 and ball milling for 24 hours, after drying, cross 40 mesh sieves, press large pieces under 5MPa pressure, Rise to 1150°C at a heating rate of 2°C / min, keep the temperature for 4 hours, and synthesize (Ba 0.55 Sr 0.45 )TiO 3 Powder;

[0063] (2) Grind the powder obtained in step (1), pass through a 40-mesh sieve, and then mix with Bi 2 o 3 , MgO, Nb 2 o 5 and other raw materials according to 0.93 (Ba 0.55 Sr 0.45 )TiO 3 -0.07Bi(Mg 2 / 3 Nb 1 / 3 )O 3 Stoichiometric ratio preparation, according to the mass ratio of raw materials: balls: deionized water = 1:5:1.55, mixed for 24 hours, after drying, passed thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com