Preparation method and applications of camel milk antioxidant polypeptides

An antioxidant peptide and camel milk technology, which is applied in the preparation method of peptides, chemical instruments and methods, peptides, etc., can solve the problems of declining corporate profits and unreasonable product structure, so as to promote health, promote economic development, and strengthen the whole body. immune effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] a. Centrifuge 100ml camel fresh milk at 4°C and 10000r / min for 20min, repeat twice, remove cream and combine supernatant;

[0035] b. Adjust the pH value of the supernatant in step a to 4.0 with HCL solution with a concentration of 1 mol / l, and put it in a refrigerator at a temperature of 4°C for 12 hours to precipitate camel cheese protein;

[0036] c. Centrifuge the precipitated part in step b at a temperature of 4°C and a speed of 10,000 r / min for 20 minutes, add the precipitate to dissolve in distilled water, and adjust the pH value to 7.0 with 1mol / l NaOH, then stir completely with a magnetic stirrer dissolve;

[0037] d. Dialyze the solution in step c with distilled water for 48 hours to desalt. The dialysis bag size is 1000 Da. Concentrate the desalted casein, freeze-dry for 24 hours at a temperature of -80°C and a pressure of 9.8 Pa in a freeze dryer. , see Table 2;

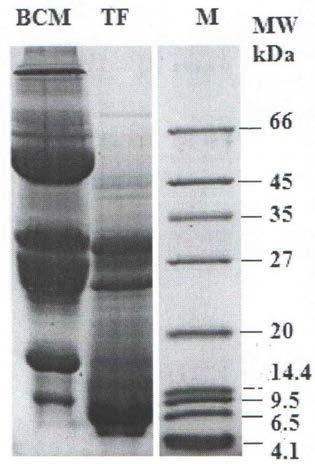

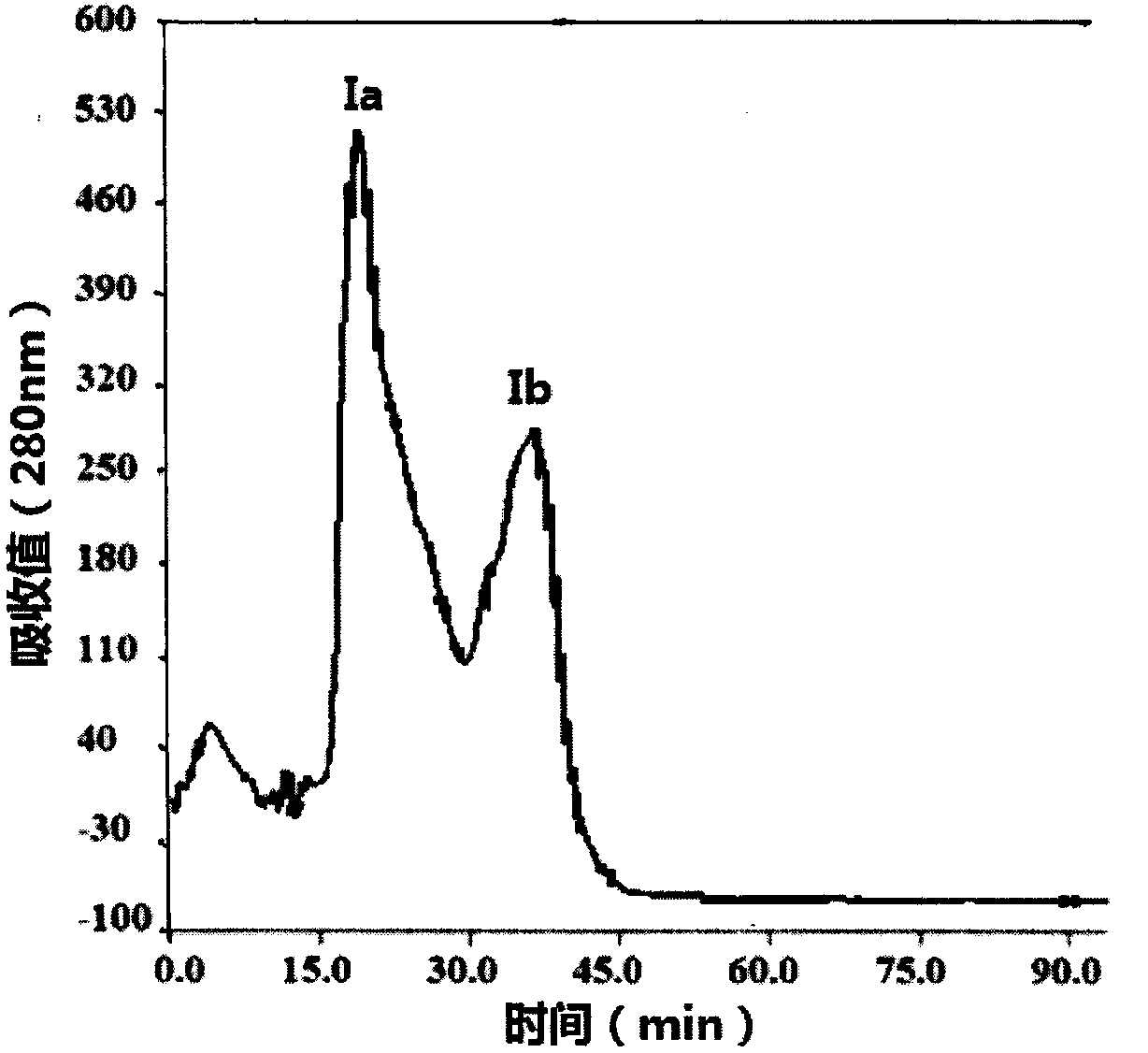

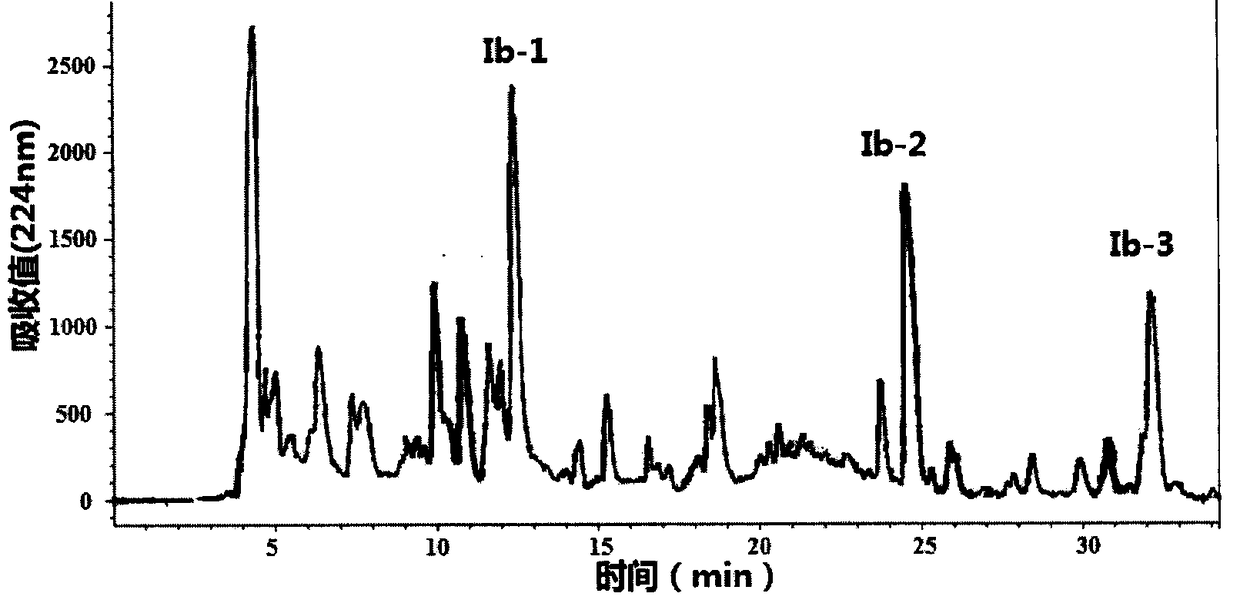

[0038] E, the casein in the step d is measured antioxidant activity by electrophoresis, measu...

Embodiment 2

[0050] a. Centrifuge 100ml camel fresh milk at 4°C and 10000r / min for 20min, repeat twice, remove cream and combine supernatant;

[0051] b. Adjust the pH value of the supernatant in step a to 4.3 with 1 mol / l HCl solution, and put it in a refrigerator at a temperature of 4°C for 12 hours to precipitate camel cheese protein;

[0052] c. Centrifuge the precipitated part in step b at a temperature of 4°C and a rotational speed of 10000r / min for 20 minutes, then add the precipitate to dissolve in distilled water, and adjust the pH value to 7.0 with 1mol / l NaOH, then stir completely with a magnetic stirrer dissolve;

[0053] d. Dialyze the solution in step c with distilled water for 48 hours to desalt. The dialysis bag size is 1000 Da. Concentrate the desalted casein, freeze-dry for 24 hours at a temperature of -80°C and a pressure of 9.8 Pa in a freeze dryer. , see Table 2;

[0054] E, the casein in the step d is measured antioxidant activity by electrophoresis, measures protei...

Embodiment 3

[0062] a. Centrifuge 100ml camel fresh milk at 4°C and 10000r / min for 20min, repeat twice, remove cream and combine supernatant;

[0063] b. Adjust the pH value of the supernatant in step a to 4.5 with 1 mol / l HCl solution, and put it in a refrigerator at a temperature of 4°C for 12 hours to precipitate camel cheese protein;

[0064] c. Centrifuge the precipitated part in step b at a temperature of 4°C and a rotational speed of 10000r / min for 20 minutes, then add the precipitate to dissolve in distilled water, and adjust the pH value to 7.0 with 1mol / l NaOH, then stir completely with a magnetic stirrer dissolve;

[0065] d. Dialyze the solution in step c with distilled water for 48 hours to desalt. The dialysis bag size is 1000 Da. Concentrate the desalted casein, freeze-dry for 24 hours at a temperature of -80°C and a pressure of 9.8 Pa in a freeze dryer. , see Table 2;

[0066] E, the casein in step d is measured antioxidative activity by electrophoresis, measures protein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com