Polyaniline-silane-nano-ceramics composite surface treatment agent

A composite surface treatment, nano-ceramic technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of weak physical bonding ability, high dependence and environmental hazards of film corrosion resistance, and achieve good compactness and strong rigidity. , the effect of reducing metal corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 配制聚苯胺-硅烷-纳米陶瓷复合表面处理剂:将质量浓度为500mg / L的磺酸基改性聚苯胺(数均分子量为20000)、200mg / L甲氧基改性聚苯胺(数均分子量为10000)、400mg / L分散性聚苯胺纳米颗粒(为气相合成的纳米级聚苯胺,粒径为15nm,PDI=0.1,数均分子量为20000)、300mg / L氟锆酸(以锆计)、100mg / L硝酸氧锆(以锆计)、10mg / Lγ-氨丙基三甲氧基硅烷、10mg / L烷基糖苷以及去离子水余量混合均匀搅拌至溶液澄清透明,即得到聚苯胺-纳米陶瓷复合表面处理剂。

[0023] 使用硝酸水溶液调节复合表面处理剂pH值至3.00±0.01,使用此复合表面处理剂浸泡处理脱脂预处理并水洗后的金属样板3分钟;

[0024] 准备板材:采用市售SPCC冷轧标准板(上海宝钢生产),规格为(150mm×70mm×0.8mm)来作为实施的金属样板。

[0025] 脱脂处理:采用市售某加热冷轧板脱脂剂,在50℃条件下浸泡冷轧板材5分钟。

[0026] 脱脂预处理后的水洗处理:在室温下自来水中摆洗1分钟。

[0027] 聚苯胺-硅烷-纳米陶瓷复合表面处理剂处理:将脱脂预处理并水洗后的金属样板在pH值至3.00±0.01的复合表面处理剂中浸泡3分钟。

[0028] 表面处理剂处理后的水洗处理:在自来水中浸泡处理复合表面处理剂处理后的金属样板30秒钟,然后使用去离子水冲洗30秒钟。此时可以取出并晾干或以冷风吹干后,以美国Filmetrics F20膜厚仪测试其膜厚(见表1中的金属表面裸膜厚度)。

[0029] 电泳涂装:

[0030] 使用关西公司生产的HT8000C水性阴极电泳涂料对表面湿润的经复合表面处理剂处理后的金属样板进行电泳,所得金属样板表面漆膜厚度为20±1μm范围内即得到试验样板。处理后的样板使用去离子水冲洗30秒钟。将水洗后的电泳后样板在180℃条件下干燥20分钟,取出后在室温下晾干。

[0031] 漆膜的性能见表1所述。

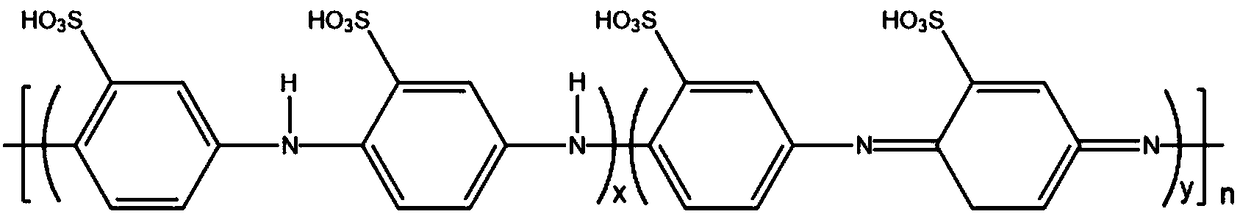

[0032] 磺酸基改性聚苯胺的分子结构:

[0033]

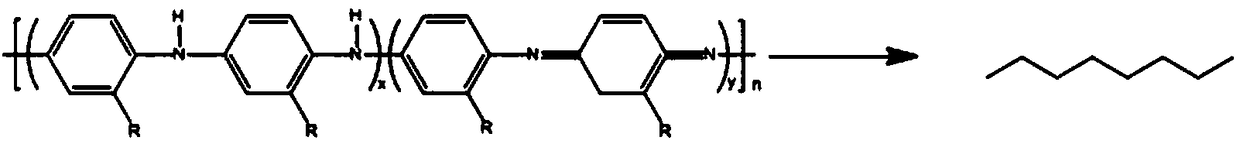

[0034] 在金属基材上的磺酸基改性聚苯胺与其它物质的反应机理:

[0035]

[0036] 磺酸基改性聚苯胺分子聚合形成聚苯胺膜;

[0037]...

Embodiment 2

[0042] 配制聚苯胺-硅烷-纳米陶瓷复合表面处理剂:将质量浓度为40mg / L的分散性聚苯胺纳米颗粒(为气相合成的纳米级聚苯胺,粒径为15nm,PDI=0.1,数均分子量为20000)、10mg / L乙氧基改性聚苯胺(数均分子量为8000)、100mg / L胺基改性聚苯胺(数均分子量12000)、5mg / Lγ-氨丙基甲基二乙氧基硅烷、100mg / L氟锆酸钾(以锆计)、5mg / L十二烷基硫酸钠以及去离子水余量混合均匀搅拌至溶液澄清透明,即得到聚苯胺-纳米陶瓷复合表面处理剂。

[0043]The prepared polyaniline-silane-nanometer ceramic composite surface treatment agent is adjusted to pH 4.20±0.01 with ammonia solution. Use this treatment solution to soak the metal sample after degreasing pretreatment and washing with water for 3 minutes.

[0044] All the other processes are the same as in Example 1.

[0045] Molecular structure of ethoxylated polyaniline:

[0046]

[0047] Table 1

[0048]

[0049] It can be seen from Table 1 that the thickness of the film formed on the surface of the metal substrate after being treated with the surface treatment agent of the present invention is far greater than the thickness of the film formed on the surface of the metal substrate after the treatment with the existing phosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com