Anode structure for large-size inner-hole iron plating repair and application

An anode structure, large size technology, applied in the field of electrochemistry, can solve the problems of slow deposition rate, difficult plating thickness, limiting current density, etc., achieve stable mechanical properties such as hardness, reduce industrial water pollution, and enhance coating uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

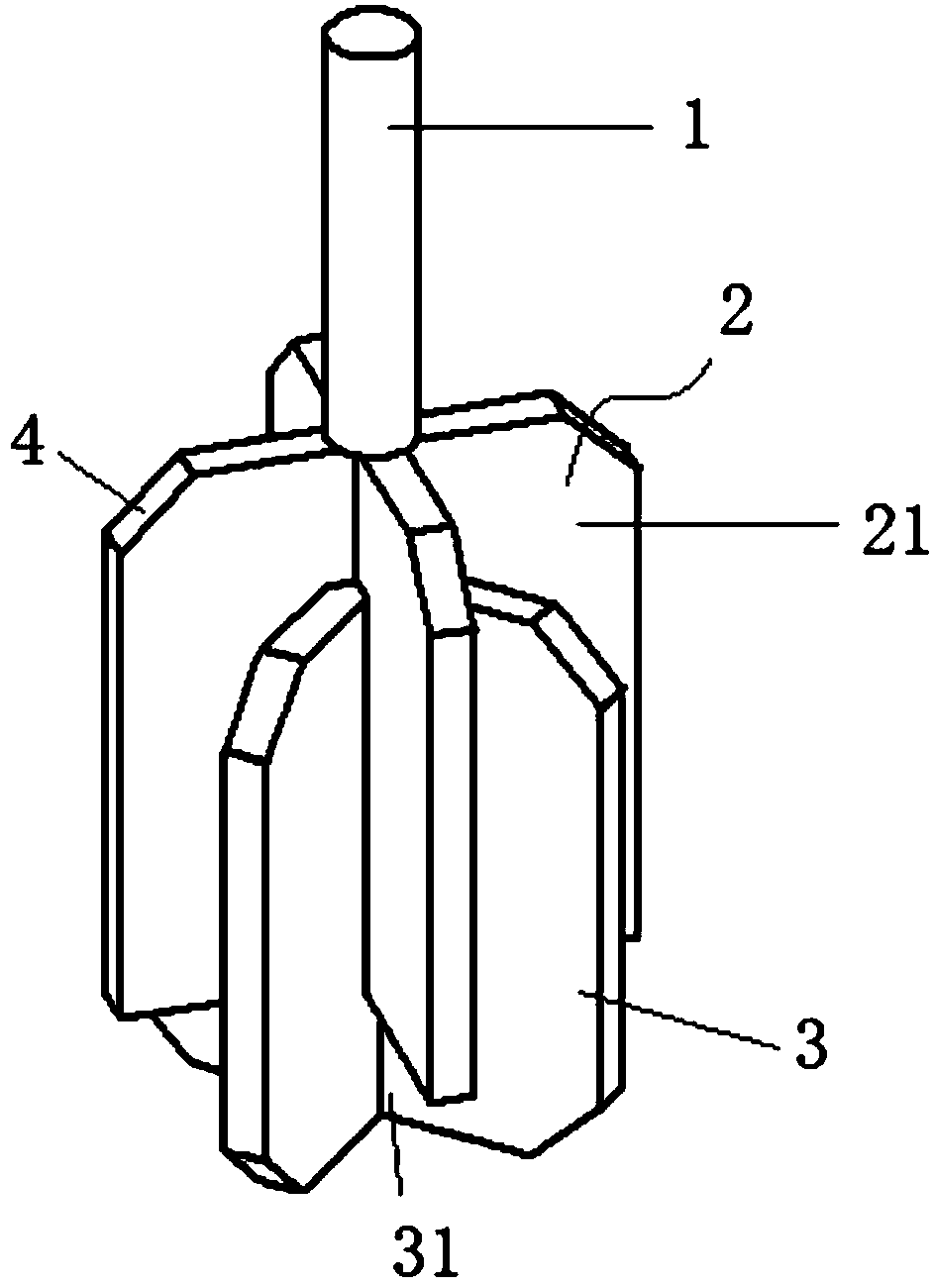

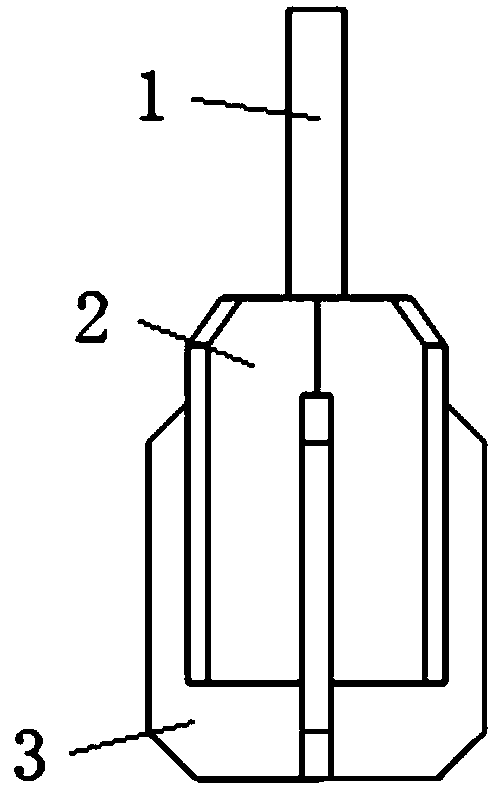

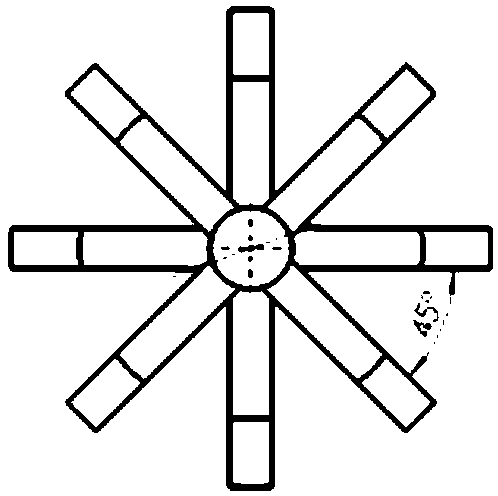

[0035] Such as Figure 1-Figure 3 As shown, an anode structure for repairing large-scale inner holes with iron plating includes a steel column 1 and a cross-connected titanium plate 2 located at the lower end of the steel column 1, and the axis of the steel column 1 is connected to the cross-connected titanium plate 2 The axes of are on the same straight line;

[0036] The lower titanium plates 3 are arranged between the adjacent support plates 21 of the cross-connected titanium plates 2, and the four lower titanium plates 3 are evenly distributed around the straight line where the axis of the steel column 1 is located.

[0037] The plane where the upper end of the lower titanium plate 3 is located is located below the plane where the upper end of the cross-connected titanium plate 2 is located and the distance is 1 / 4L, and the plane where the lower end of the lower titanium plate 3 is located is located at the plane where the lower end of the cross-connected titanium plate 2 ...

Embodiment 2

[0044] Such as Figure 4 As shown, a large-size inner hole iron plating repair device includes an electroplating tank 5 and an acid-resistant pump 6 located in the electroplating tank 5, a tooling fixture 8 for clamping a workpiece 7 with a large-size inner hole, and as implemented The anode structure of the iron-plated repair of the large-scale inner hole described in example 1;

[0045] The fixture 8 is in the shape of an inverted U, its lower end opening has a clamping portion 81 for clamping the workpiece 7, its upper end has a hole 82 through which the steel column 1 passes and is rotatably connected with the steel column 1, The upper end of the steel column 1 passes through the hole 82 to connect with the rotating device, the cross-connected titanium plate 2 and the lower titanium plate 3 are located in the space surrounded by the workpiece 7,

[0046] The input end 61 of the acid-resistant pump 6 is located outside the workpiece 7 , and the output end 62 of the acid-re...

Embodiment 3

[0048] Such as Figure 5-Figure 7 As shown, a method for repairing a large-sized inner hole coating by the large-sized inner hole iron plating repair device described in Embodiment 2 has the following steps:

[0049]The workpiece 7 is pre-plated and started to be plated;

[0050] The workpiece 7 is a cylinder simulation piece with a diameter of 456mm and a length of 500mm;

[0051] The anode structure repaired by the iron-plating of the large-size inner hole is connected to the positive pole, the workpiece 7 is connected to the negative pole, and an insulating layer is provided on the outside of the workpiece 7;

[0052] Using the method of controlling the forward voltage U positive and reverse voltage U reverse symmetrical AC activation, after the surface of the workpiece 7 fully reaches the micro-melt activation state, select appropriate electrical parameters to perform AC starting plating, AC transition plating, small DC plating, DC transition plating and large DC plating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com