Dynamic performance testing device for belt transmission system

A technology of system dynamics and testing equipment, which is applied in the field of mechanical transmission, can solve the problems of V-belt and tensioner wear, large vibration and noise of the transmission system, and short service life, and achieves a simple structure, high versatility, and easy realization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

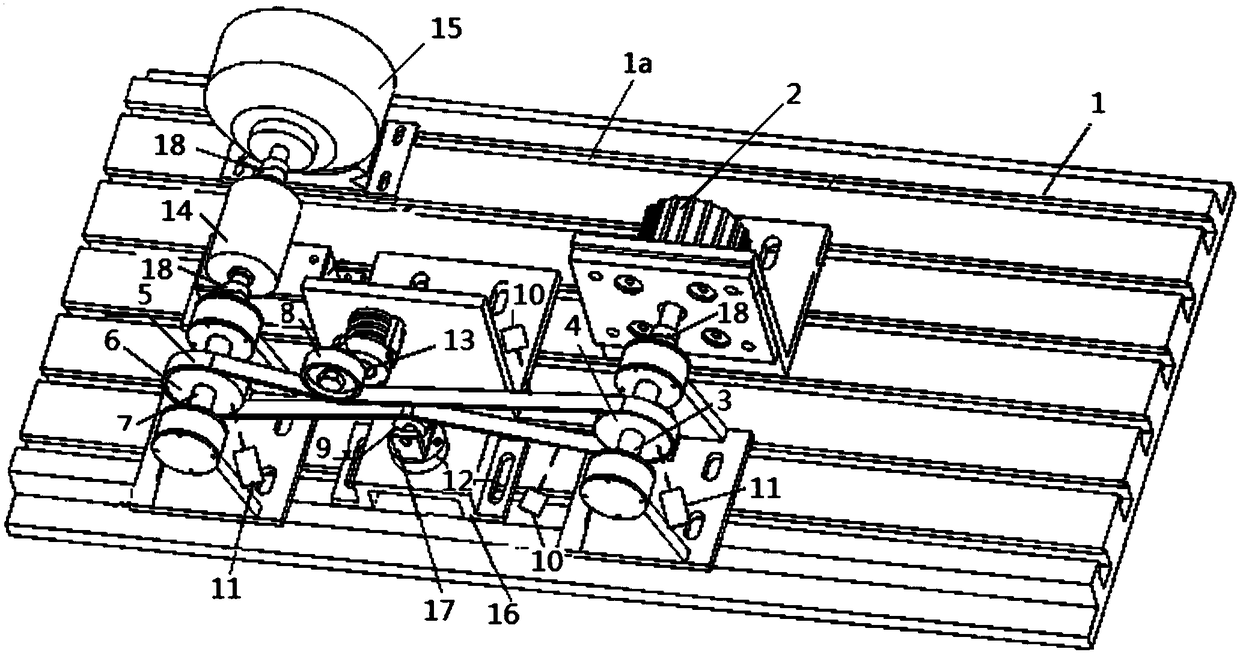

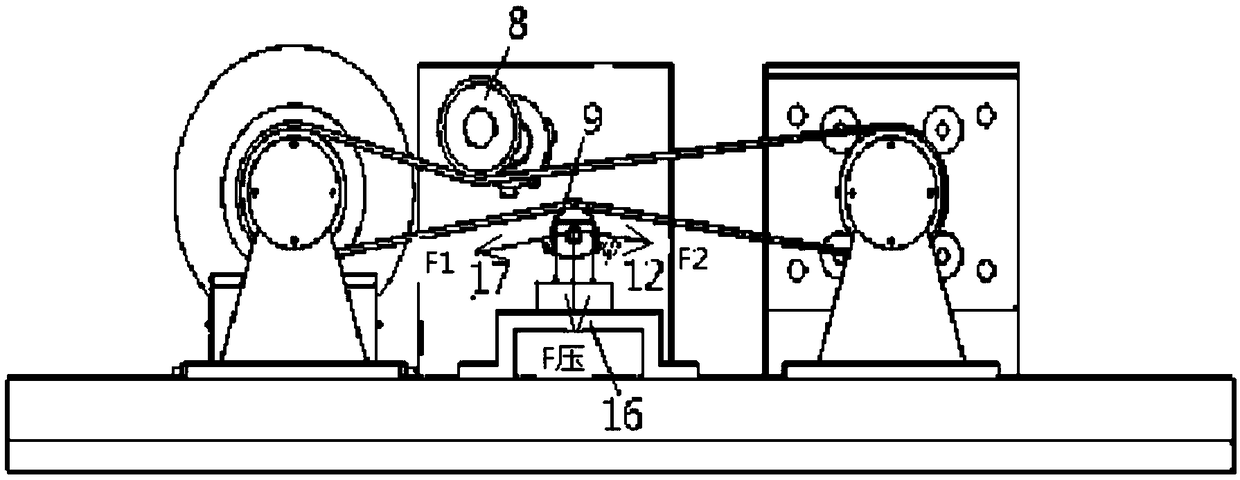

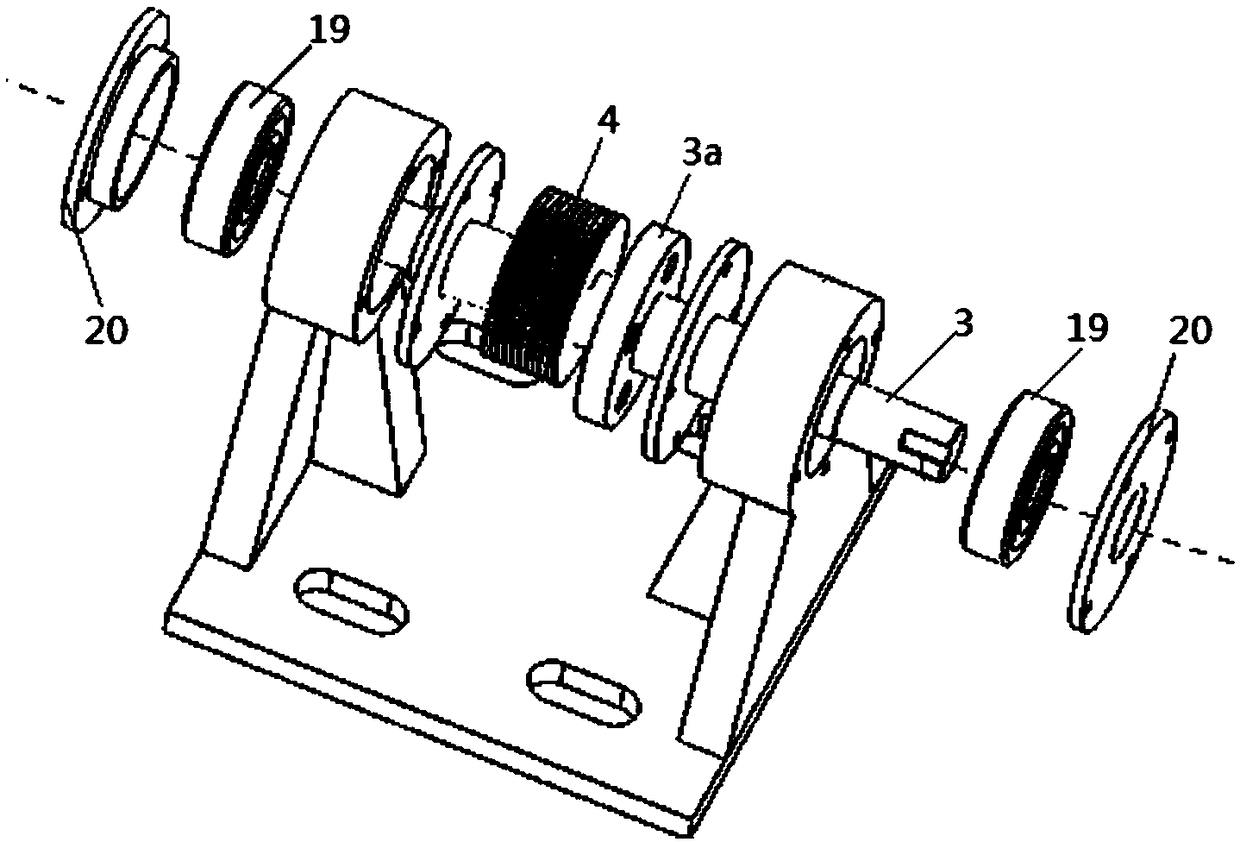

[0025] combine figure 1 — figure 2 As shown, a test device for dynamic performance of a belt transmission system is mainly composed of a test platform 1, a servo motor 2, an input shaft 3, a driving wheel 4, a belt 5, a driven wheel 6, an output shaft 7, a tensioner 8, and an idler wheel 9 , Laser displacement sensor 10, laser rotational speed sensor 11, pressure sensor 12, potentiometer 13, torque sensor 14, magnetic powder brake 15, pressure sensor mount 16, idler mount 17, coupling 18, etc.

[0026] The servo motor 2, the input shaft 3, the driving wheel 4, the belt 5, the driven wheel 6 and the output shaft 7 are connected in sequence and installed on the test platform 1. A tensioner 8 is arranged above the belt 5, and an idler 9 is arranged below the belt 5, thereby forming a belt transmission system. The tensioning pulley of driving pulley 4, dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com