A surface wave plasma generate device for a cylinder

A plasma, cylindrical surface technology, applied in the direction of plasma, electrical components, etc., can solve the problems of unstable structure, complexity, large loss, etc., and achieve the effect of adjustable parameters, considerable size, and small loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

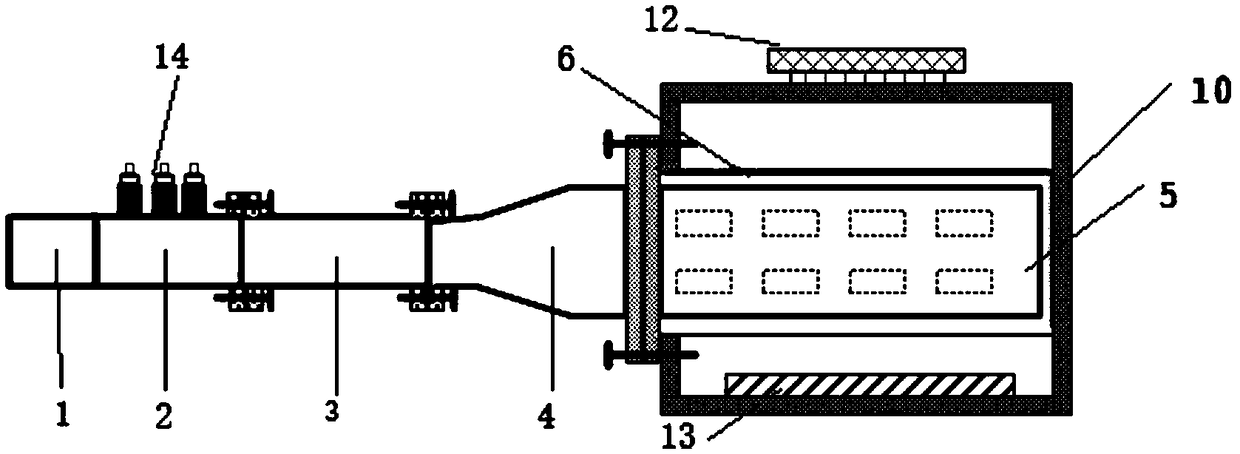

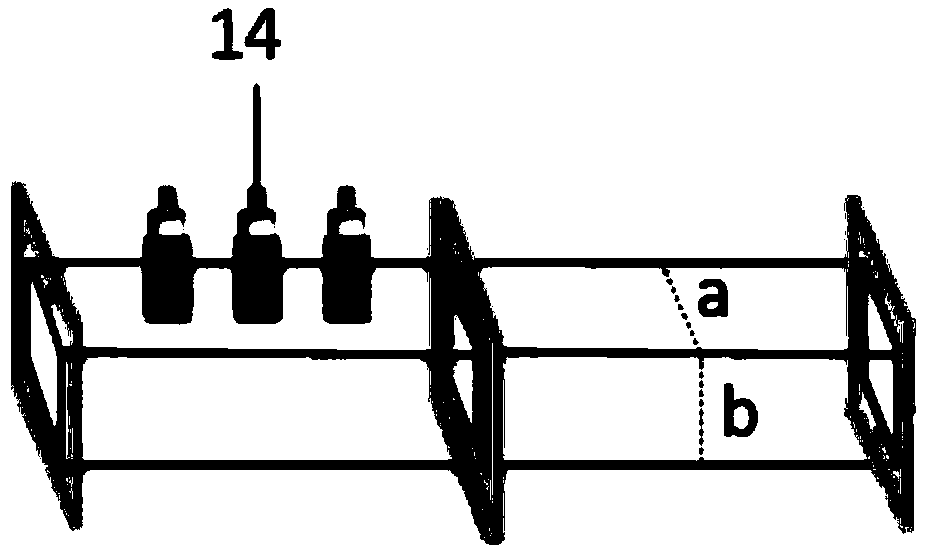

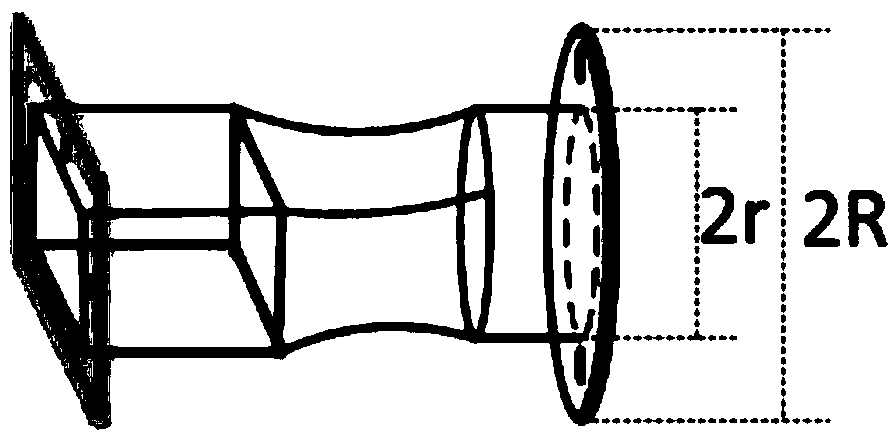

[0031] The cylindrical surface wave plasma generation device includes a high-frequency power supply 1, an impedance adjustment unit 2, an energy transmission waveguide 3, a waveguide converter 4 and a cylindrical slotted waveguide 5 connected in sequence, see figure 1 , the outer wall of the cylindrical slotted waveguide 5 is nested with a dielectric tube 6, and the material of the dielectric tube 6 is one of quartz glass, Pyrex glass or alumina ceramics. A reaction chamber 10 is sheathed on the periphery of the dielectric tube 6, a vacuum cavity is formed between the outer wall of the dielectric tube 6 and the inner wall of the reaction chamber 10, and the cylindrical slotted waveguide 5 is provided with multiple slots. seam.

[0032] The high-frequency power source is preferably a microwave source of 2.45 GHz. The parameters of 2.45 GHz ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com