Preparation method of rebaudioside A, enzyme for preparing rebaudioside A, and use thereof

A technology of rebaudioside and transferase, applied in the field of biomedicine, can solve the problems of complicated process steps, low purity and yield, and high energy consumption, and achieve the effects of simple process, few purification steps and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

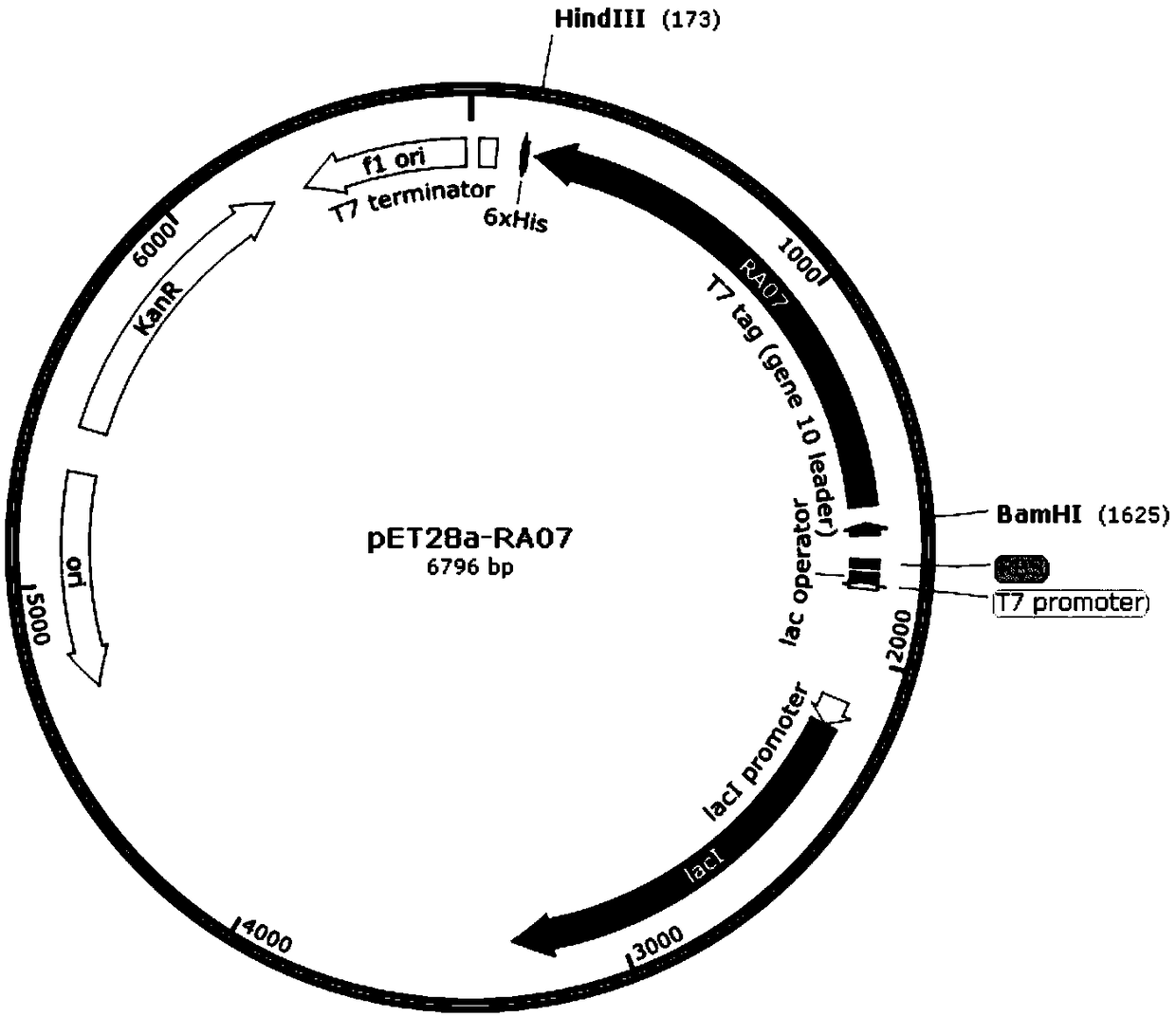

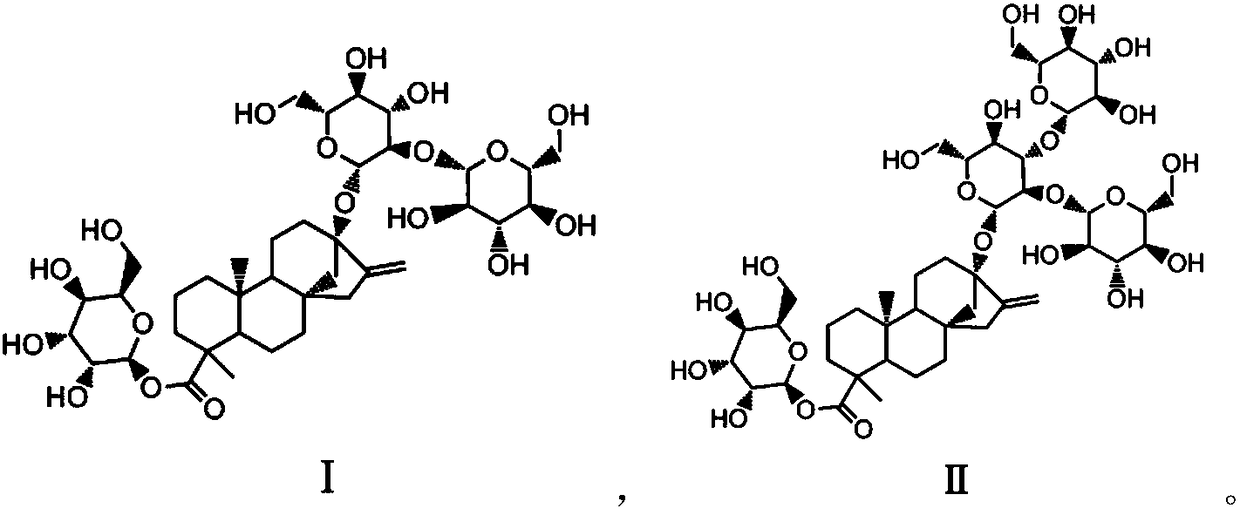

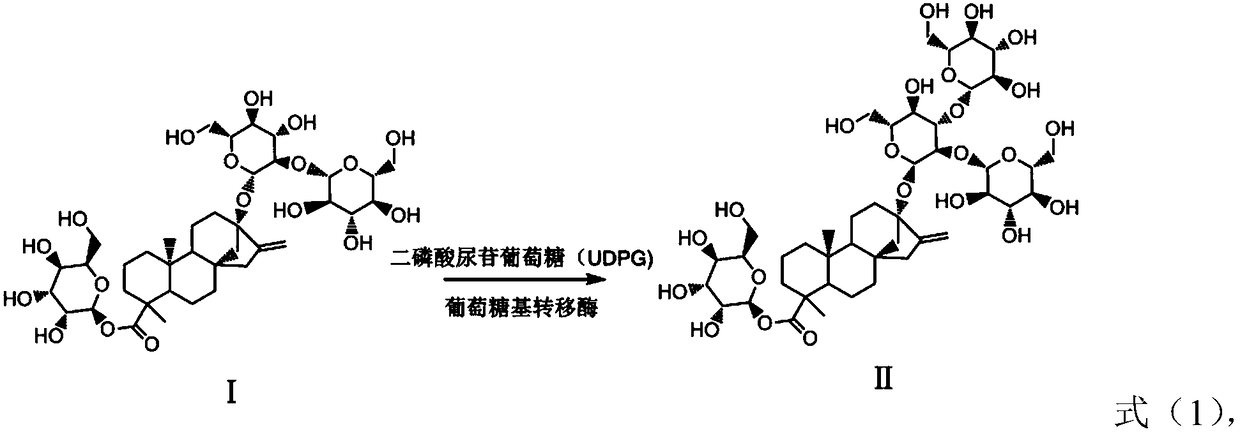

Method used

Image

Examples

Embodiment 1

[0057] A preparation method of rebaudioside A, comprising:

[0058]In sodium phosphate buffer, add stevioside 100g, sucrose 80g and UDP 1g respectively, stir until completely dissolved; continue to add 50g of glucosyltransferase RA07 enzyme powder and 50g of sucrose synthase (derived from Arabidopsis thaliana, NP_197583), react The total system volume is 1L, and the pH of the system is adjusted to 7.4; the reaction is carried out at a constant temperature of 37°C and a stirring rate of 200rpm for 16h, and the conversion rate is measured to be 99%. The protein was denatured and filtered to remove the protein, and the filtrate was collected and spray-dried to obtain a crude product of rebaudioside A. After the crude product of rebaudioside A was purified by silica gel resin separation, crystallization and other post-treatments, 96.22 g of rebaudioside A was obtained. Purity >95%.

Embodiment 2

[0060] A preparation method of rebaudioside A, comprising:

[0061] In the sodium phosphate buffer, add stevioside 100g and UDPG 1.5g respectively, stir until completely dissolved; continue to add 50g of glucosyltransferase RA07 enzyme powder, the total volume of the reaction system is 1L, adjust the pH of the system to 7.4; , 250rpm stirring rate under the reaction 16h, the conversion rate is 99% measured by experiments, after the reaction is completed, the reaction solution is heated to 100 ℃ heat treatment for 0.5h, the RA07 protein denatured and filtered to remove the protein, the filtrate is collected and then spray-dried to obtain Laibao Rebaudioside A crude product, the rebaudioside A crude product was purified by silica gel resin separation, crystallization and other post-treatments to obtain 95.82 g of rebaudioside A, with a purity of >95%.

Embodiment 3

[0063] A preparation method of rebaudioside A, comprising:

[0064] In the sodium phosphate buffer, add stevioside 100g and UDPG 1.5g respectively, stir until completely dissolved; continue to add 50g of glucosyltransferase RA07 enzyme powder, the total volume of the reaction system is 1L, adjust the pH of the system to 6.0; , 200rpm stirring rate under the reaction 16h, the conversion rate is 97% measured by experiments, after the reaction is completed, the reaction solution is heated to 100 ℃ heat treatment for 0.5h, the RA07 protein is denatured and filtered to remove the protein, after the filtrate is collected, it is spray-dried to obtain Laibao Rebaudioside A crude product, the rebaudioside A crude product was purified by silica gel resin separation, crystallization and other post-treatments to obtain 93.17 g of rebaudioside A, with a purity of >95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com