A high-efficiency control method of water and fertilizer for corn large ridge and double-row drip irrigation under plastic film in cold and semi-arid regions

A technology of drip irrigation under film and double rows of large ridges is applied in fertilization methods, botanical equipment and methods, watering devices, etc. The effect of strong root and seedling, increase of root biomass, and promotion of growth and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

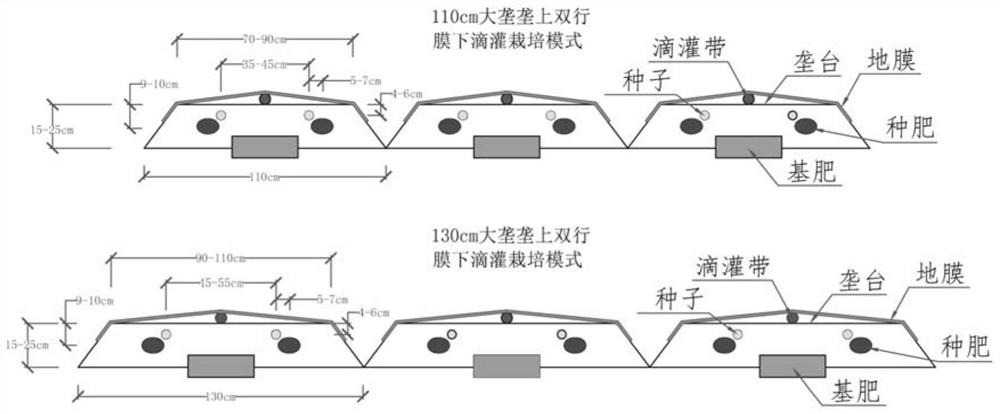

[0061] Example 1. High-efficiency control method of water and fertilizer under plastic film drip irrigation in two rows of large ridges of corn in semi-arid regions in cold regions

[0062] Select areas / years with low rainfall, poor soil fertility or sandy loam fields, and follow the steps below:

[0063] a. After the completion of corn site preparation, a large ridge of 110cm was erected. Before sowing, the base fertilizer (containing N≥46% urea 110kg / hm 2 , containing N≥18%, P 2 o 5 ≥46% diammonium phosphate 120kg / hm 2 , including K 2 O≥50% potassium sulfate 65kg / hm 2 , containing Zn≥23% zinc sulfate 30kg / hm 2 ) and seed fertilizer (urea 12kg / hm 2 , diammonium phosphate 21kg / hm 2 , Potassium sulfate 18kg / hm 2 ) respectively mixed evenly for subsequent use. When sowing, base fertilizer was applied 15 cm below the sowing row, and seed fertilizer was applied at a horizontal distance of 5 cm and a depth of 9 cm on the furrow side of the sowing row.

[0064] b. After so...

Embodiment 2

[0076] Example 2. High-efficiency control method of water and fertilizer for corn big ridge and double-row drip irrigation under plastic film in semi-arid area in cold region

[0077] Select areas / years with better rainfall, higher basic fertility or silt loam and clay loam fields, and follow the steps below:

[0078] a. After the completion of corn site preparation, a large ridge of 110cm was erected. Before sowing, the base fertilizer (containing N ≥ 46% urea 105kg / hm 2 , containing N≥18%, P 2 o 5 ≥46% diammonium phosphate 90kg / hm 2 , including K2 O≥50% potassium sulfate 50kg / hm 2 , containing Zn≥23% zinc sulfate 20kg / hm 2 ) and seed fertilizer (urea 10kg / hm 2 , diammonium phosphate 18kg / hm 2 , Potassium sulfate 15kg / hm 2 ) respectively mixed evenly for subsequent use. When sowing, base fertilizer was applied 20 cm below the sowing row, and seed fertilizer was applied at a horizontal distance of 7 cm and a depth of 10 cm on the furrow side of the sowing row.

[0079...

example 3

[0091] Example 3. High-efficiency control method of water and fertilizer for corn large ridge and double-row drip irrigation under plastic film in semi-arid area in cold region

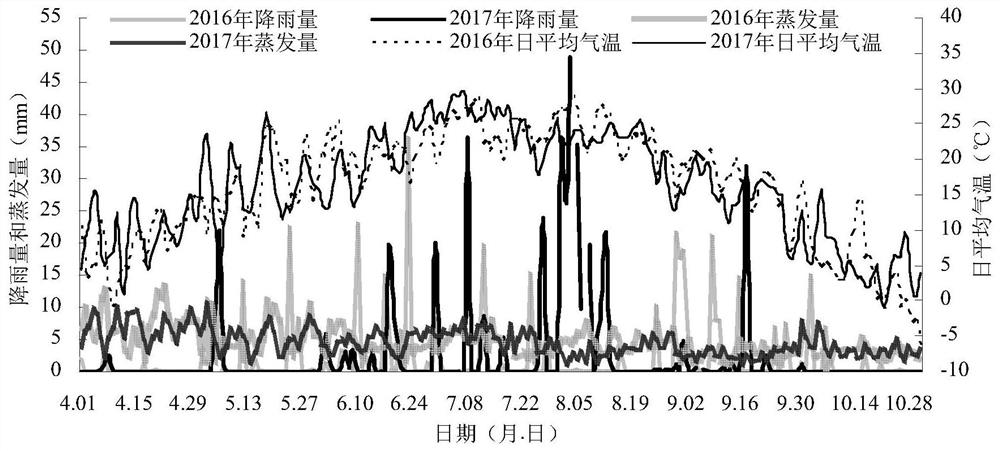

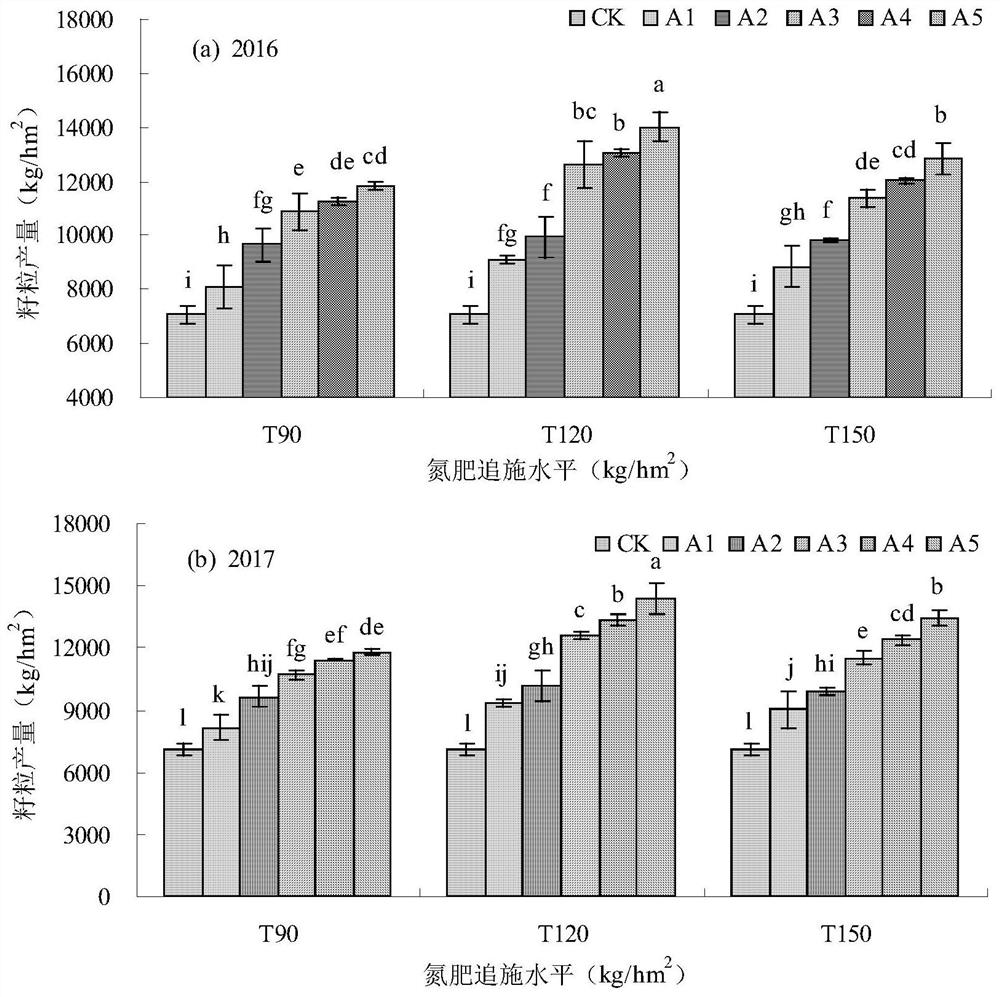

[0092] 1 Materials and methods

[0093] 1.1 Overview of the test site

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com