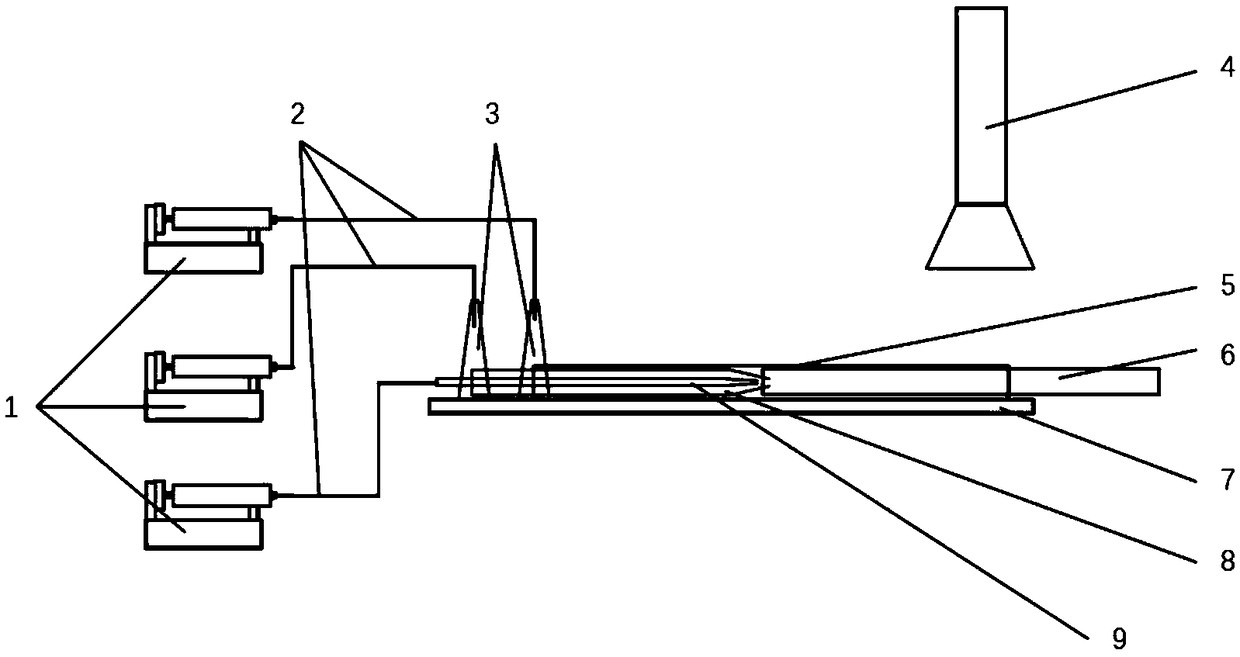

Double emulsified glass capillary microfluidic chip and phase change microcapsule prepared thereby

A technology of glass capillary and microfluidic chip, which is applied in the field of preparation of phase change microcapsule materials, to achieve the effects of reducing preparation time, increasing practical value and improving controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing phase-change microcapsules using the above-mentioned double emulsified glass capillary microfluidic chip, comprising the following steps:

[0039] (1) Get 9ml heptadecane as dispersed phase 1 with 10ml syringe, get 9ml HDDA containing 2% mass fraction Span 80 and 2% mass fraction photocuring agent with 10ml syringe as dispersed phase 2, get 15ml with 20ml syringe The 2% mass fraction of polyvinyl alcohol aqueous solution is used as the continuous phase; the dispersed phase 1, the dispersed phase 2 and the continuous phase are respectively pushed into the Teflon catheter from the syringe pump and passed into the double emulsified glass capillary microfluidic chip, wherein the dispersed phase The first is to pass into the microfluidic chip from the small tip glass capillary, the dispersed phase 2 is passed into the microfluidic chip from the first closed liquid storage tank, and the continuous phase is passed into the microfluidic chip from the secon...

Embodiment 2

[0043] The flow rate of the syringe pump was adjusted to 150 μl / min, 20 μl / min and 10 μl / min in turn, and other steps were the same as in Example 1. The thickness of the finally obtained capsule shell is about 50 μm, the diameter of the capsule core is about 240 μm, the total diameter of the capsule is about 340 μm, and the polydispersity coefficient is less than 3%.

Embodiment 3

[0045] The flow rate of the syringe pump was adjusted to 800 μl / min, 5 μl / min and 5 μl / min respectively, and other steps were the same as in Example 1. The thickness of the finally obtained capsule shell is about 10 μm, the diameter of the capsule core is about 20 μm, the total diameter of the capsule is about 60 μm, and the polydispersity coefficient is less than 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com