Electric smelting saddle-shaped pipe fitting cambered surface wiring machine and processing method

A technology of wiring machine and pipe fittings, which is applied in the field of arc surface wiring machines and processing of electric fusion saddle-shaped pipe fittings, can solve the problems of difficult to guarantee processing accuracy, increase the risk of enterprise operation, and cannot process at one time, so as to achieve high processing efficiency and easy promotion , the effect of small individual differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Such as Figure 4 The arc-shaped wiring machine for electrofusion saddle-shaped pipe fittings shown includes a base 1, an X-axis track 21, a Y-axis track 31, a Z-axis track 41 and a milling mechanism 5, an X-axis track 21, a Z-axis track 41 and a milling mechanism 5 are installed on the upper surface of the base 1, the Z-axis track 41 is installed in the middle of the upper surface of the base 1, the X-axis track 21 is located on the left side of the Z-axis track 41, the milling mechanism 5 is located on the right side of the Z-axis track 41, and the milling The mechanism 5 is located in front of the Z-axis track 41 ; the Y-axis track 31 is vertically arranged above the X-axis track 21 . An X-axis lead screw 22 and an X-axis slide plate 24 are installed on the X-axis rail 21, and an X-axis lead screw nut is threaded on the X-axis lead screw 22, and the upper end of the X-axis lead screw nut is fixedly connected to the X-axis slide plate 24 On the lower surface, the X-a...

Embodiment 2

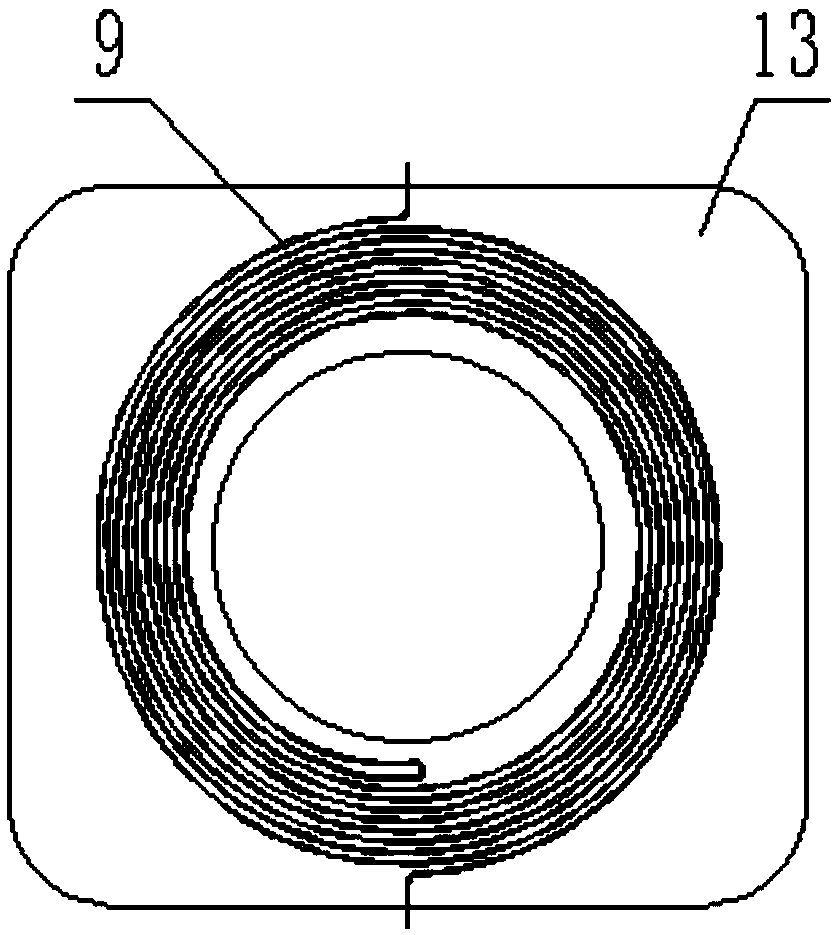

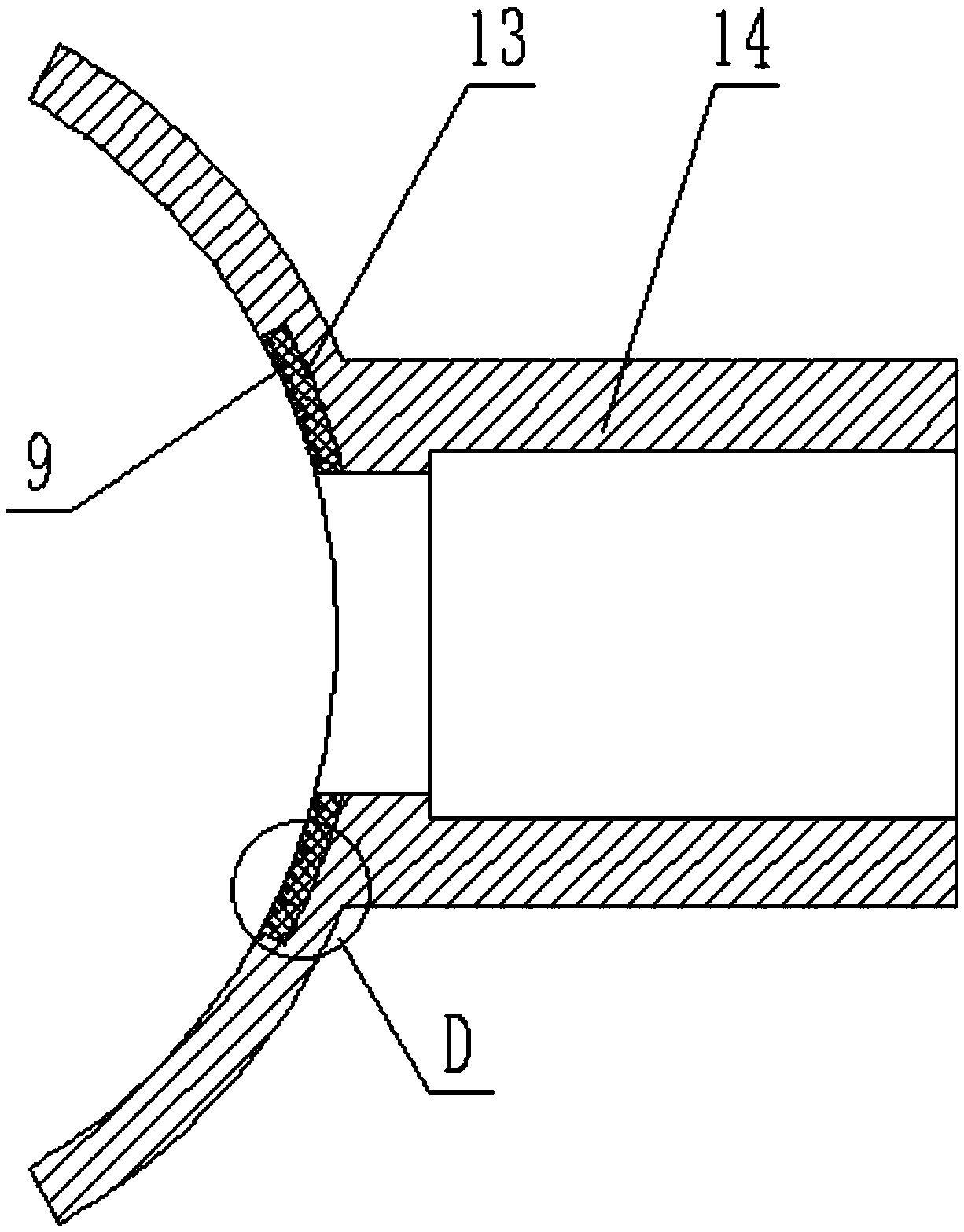

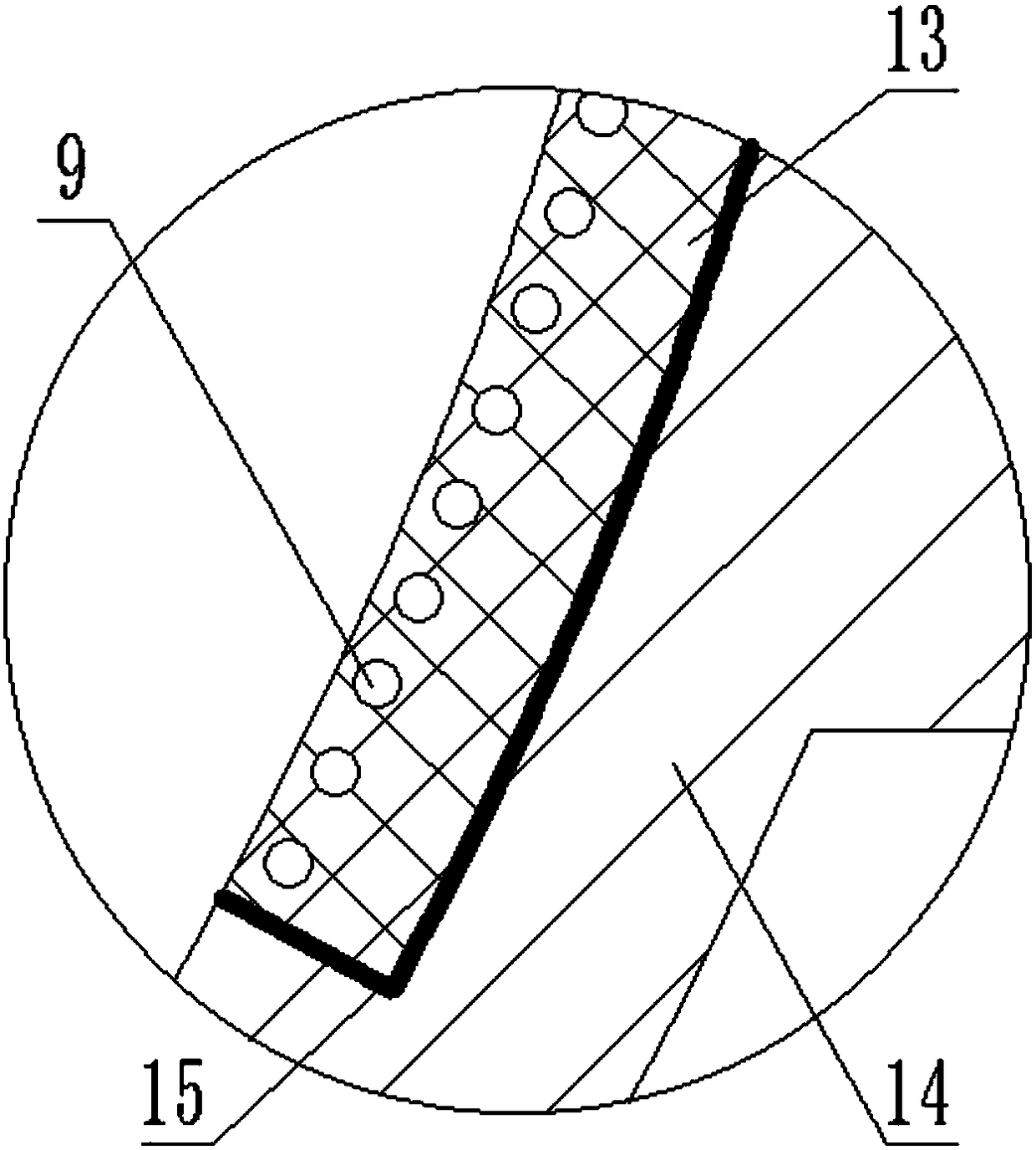

[0060] Such as Figure 10-13 Shown, embodiment 2 is improved on the basis of embodiment 1. The wiring tool in Embodiment 2 includes a knife handle 81, a repressing wheel 82 and a wire passing blade 83. The knife handle 81 is coaxially fixed on the right end of the A-axis (the knife handle 81 and the A-axis are integrally processed), and the knife handle 81 The right end of the re-pressing wheel 82 is equipped with a re-pressing wheel 82, and a thread-passing blade 83 is installed on the right-hand side of the re-pressing wheel 82. The protrusion 84 is located below the thread passing blade 83 . There is also a wiring through-hole 85 arranged obliquely in the re-pressing wheel 82 , and the wiring through-hole 85 extends to the inside of the wire-passing blade 83 and passes out from the lower part of the cutting edge of the wire-passing blade 83 . A wire passing hole 86 is also provided in the knife handle 81 along the axial direction of the knife handle 81 , and the wire pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com