Anti-aging anti-wrinkle low-atomization-value water-based automobile leather and preparation method thereof

An anti-aging, low-fogging technology, applied in chemical instruments and methods, vehicle parts, layered products, etc., can solve the problems of poor aging resistance, high T-VOC, and poor environmental protection of PVC artificial leather, and achieve good insulation , low volatility, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

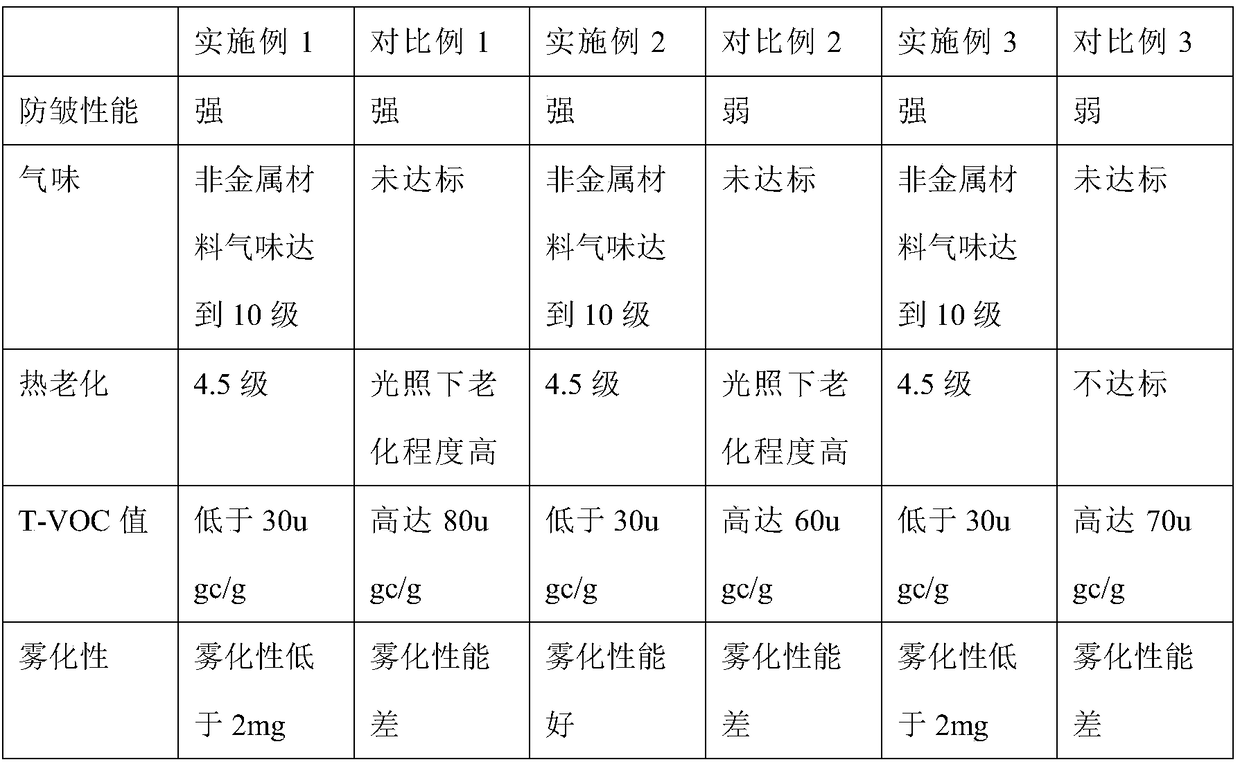

Examples

Embodiment 1

[0022] Step 1: In parts by mass, mix 100 parts of 2600 type polyvinyl chloride resin powder, 80 parts of TOTM plasticizer, 2 parts of calcium zinc heat stabilizer and 1 part of U485 type light stabilizer, and stir for 7 minutes;

[0023] Step 2: Put the mixture stirred in Step 1 into the internal mixer, plasticize at 100°C for 3 minutes, then add to the open mixer to continue plasticizing for 20 minutes, and set the temperature of the open mixer to 145°C;

[0024] Step 3: Press the plasticized mixture into a film through a four-roller calender; the temperature of the four rolls is set at 185°C, 180°C, 170°C, and 160°C respectively, and compounded with the base cloth, and then cooled by the cooling wheel Winding to obtain semi-finished products;

[0025] Step 4: Send the semi-finished product into the foaming oven for low-temperature foaming; the foaming oven is a 6-stage foaming oven, and the oven temperature is set as: 160 degrees for the first stage, 170 degrees for the seco...

Embodiment 2

[0028] Step 1: In terms of parts by mass, mix 100 parts of 2600 type polyvinyl chloride resin powder, 80 parts of TOTM plasticizer, 3 parts of calcium zinc heat stabilizer and 1 part of U485 type light stabilizer, and stir for 7 minutes;

[0029] Step 2: Put the mixture stirred in step 1 into the internal mixer, plasticize at 100°C for 3 minutes, then add to the open mixer and continue to plasticize for 20 minutes, and set the temperature of the open mixer to 155°C;

[0030] Step 3: Press the plasticized mixture into a film through a four-roller calender; the temperature of the four rolls is set at 185°C, 180°C, 170°C, and 160°C respectively, and compounded with the base cloth, and then cooled by the cooling wheel Winding to obtain semi-finished products;

[0031] Step 4: Send the semi-finished product into the foaming oven for low-temperature foaming; the foaming oven is a 6-stage foaming oven, and the oven temperature is set as: 160 degrees for the first stage, 170 degrees f...

Embodiment 3

[0034] Step 1: In parts by mass, mix 100 parts of 2600 type polyvinyl chloride resin powder, 80 parts of TOTM plasticizer, 2 parts of calcium zinc heat stabilizer and 1 part of U485 type light stabilizer, and stir for 6 minutes;

[0035] Step 2: Put the mixture stirred in Step 1 into the internal mixer, plasticize at 100°C for 3 minutes, then add to the open mixer and continue to plasticize for 20 minutes, and set the temperature of the open mixer to 150°C;

[0036] Step 3: Press the plasticized mixture into a film through a four-roller calender; the temperature of the four rolls is set at 185°C, 180°C, 170°C, and 160°C respectively, and compounded with the base cloth, and then cooled by the cooling wheel Winding to obtain semi-finished products;

[0037] Step 4: Send the semi-finished product into the foaming oven for low-temperature foaming; the foaming oven is a 6-stage foaming oven, and the oven temperature is set as: 160 degrees for the first stage, 170 degrees for the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com