Preparation method of sodium titanium phosphate material

A technology of sodium titanium phosphate and titanium source, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high cost and incapable of large-scale production, and achieve low cost, good crystal shape and processing performance, and energy consumption low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: This sodium titanium phosphate material is prepared by the following process steps.

[0022] Mix sodium dihydrogen phosphate monohydrate, titanium dioxide, and diammonium hydrogen phosphate evenly according to the molar ratio of 1:2:2; use a stirring ball mill to mill at a speed of 500r / min for 2 hours; The heating time was 2 hours at 900°C in air environment, and the heating rate was 5°C / min; further mechanical crushing was carried out to obtain sodium titanium phosphate material.

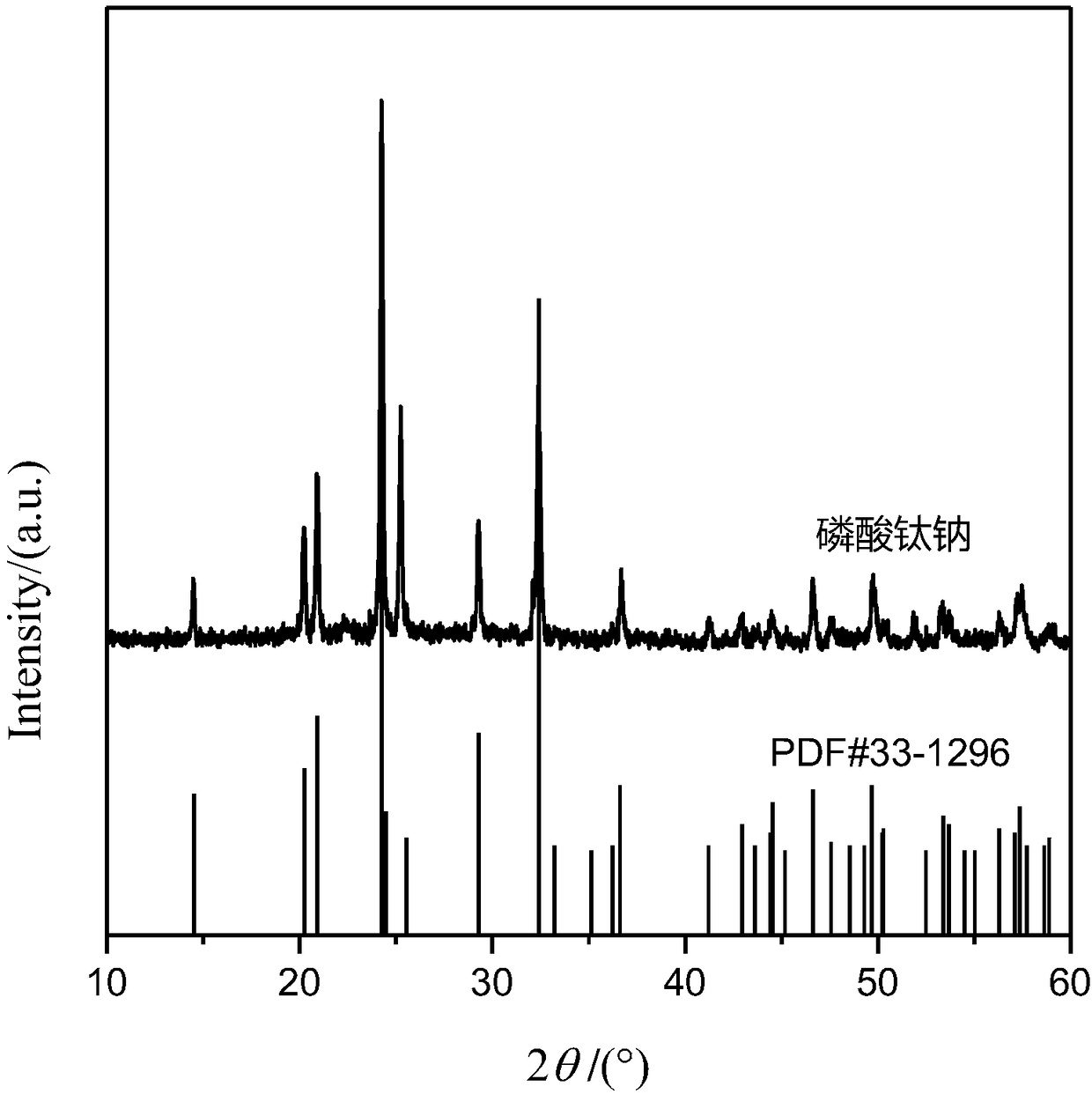

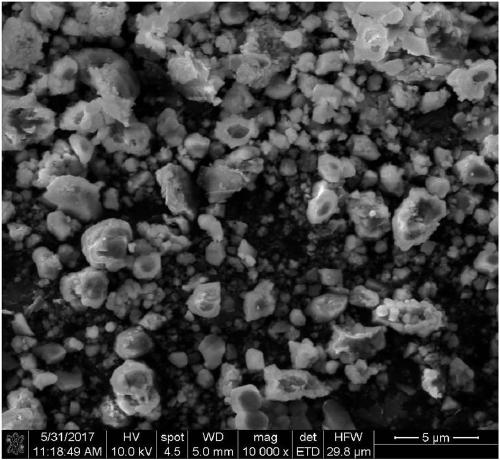

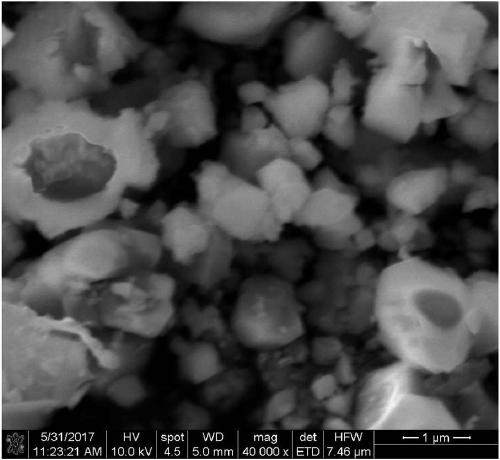

[0023] From figure 1 It can be seen that the XRD spectrum of the prepared sodium titanium phosphate material can correspond well with the JCPDS card (No.33-1296) of the standard sodium titanium phosphate material, indicating that the prepared sodium titanium phosphate material has a better crystal structure and well maintained The R3c spatial structure was determined, and the modification process did not change the crystal structure of lithium titanate. From figure 2 and ...

Embodiment 2

[0025] The sodium dihydrogen phosphate monohydrate in Example 1 is adjusted to sodium dihydrogen phosphate dihydrate, and the rest are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0027] The sodium dihydrogen phosphate monohydrate in Example 1 is adjusted to sodium dihydrogen phosphate, and the rest are the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com