Silicon rubber thermal insulation material and preparation method thereof

A thermal insulation material, silicone rubber technology, applied in the field of silicone rubber thermal insulation materials and its preparation, can solve the problems of low strength, limited ablation resistance and flame retardancy of pure silicone rubber, low cohesive energy between molecules, etc., to achieve elasticity Good, strong resistance to small molecule migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

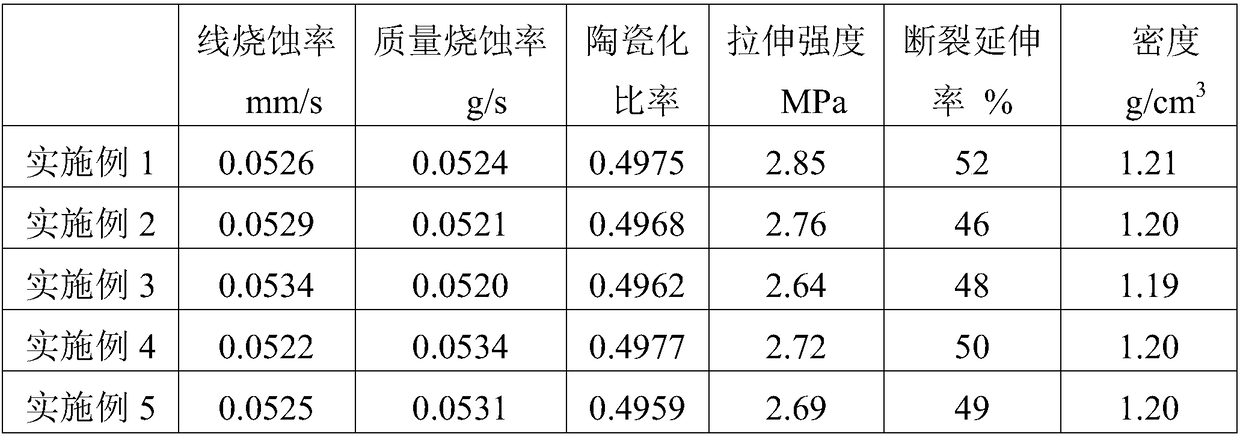

Examples

Embodiment 1

[0023] This embodiment provides a silicone rubber thermal insulation material, which is prepared from the following raw materials: 50 parts of methyl vinyl silicone rubber, 50 parts of methyl vinyl phenyl silicone rubber, 25 parts of white carbon black, 8 parts of nano calcium carbonate parts, carbon fiber 12 parts, 2,5-dimethyl-2,5-bis-hexane 1.0 parts.

[0024] The preparation method of the silicone rubber thermal insulation material of the present embodiment comprises the following steps:

[0025] (1) Weighing methyl vinyl silicone rubber and methyl vinyl phenyl silicone rubber, adding them into a mixer and kneading to a transparent state to prepare a silicone rubber matrix;

[0026] (2) Take white carbon black and carbon fiber and add in the silicone rubber matrix that step (1) obtains, knead until mixing;

[0027] (3) take nano-calcium carbonate, add in the silicone rubber matrix that obtains in step (2), knead to mix;

[0028] (4) Weigh 2,5-dimethyl-2,5-bis-hexane, add...

Embodiment 2

[0031] This embodiment provides a silicone rubber thermal insulation material, which is prepared from the following raw materials: 40 parts of methyl vinyl silicone rubber, 60 parts of methyl vinyl phenyl silicone rubber, 20 parts of white carbon black, 15 parts of nanometer calcium carbonate 10 parts of carbon fiber, 1.5 parts of 2,5-dimethyl-2,5-bis-hexane.

[0032] The preparation method of the silicone rubber thermal insulation material of the present embodiment comprises the following steps:

[0033] (1) Weighing methyl vinyl silicone rubber and methyl vinyl phenyl silicone rubber, adding them into a mixer and kneading to a transparent state to prepare a silicone rubber matrix;

[0034] (2) Take white carbon black and carbon fiber and add in the silicone rubber matrix that step (1) obtains, knead until mixing;

[0035] (3) take nano-calcium carbonate, add in the silicone rubber matrix that obtains in step (2), knead to mix;

[0036] (4) Weigh 2,5-dimethyl-2,5-bis-hexane...

Embodiment 3

[0039] This embodiment provides a silicone rubber thermal insulation material, which is prepared from the following raw materials: 60 parts of methyl vinyl silicone rubber, 40 parts of methyl vinyl phenyl silicone rubber, 30 parts of white carbon black, 2 parts of nanometer calcium carbonate parts, carbon fiber 15 parts, 2,4-dimethyl 2,4-bishexane 0.5 parts.

[0040] The preparation method of the silicone rubber thermal insulation material of the present embodiment comprises the following steps:

[0041] (1) Weighing methyl vinyl silicone rubber and methyl vinyl phenyl silicone rubber, adding them into a mixer and kneading to a transparent state to prepare a silicone rubber matrix;

[0042] (2) Take white carbon black and carbon fiber and add in the silicone rubber matrix that step (1) obtains, knead until mixing;

[0043] (3) take nano-calcium carbonate, add in the silicone rubber matrix that obtains in step (2), knead to mix;

[0044] (4) Weigh 2,4-dimethyl 2,4-bis-hexane,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com