A purging device for heat treatment of metal plate and strip

A technology of metal strips and nozzles, applied in heat treatment furnaces, heat treatment equipment, quenching devices, etc., can solve the problems of incomplete removal of residual water on the lower surface, incomplete drying of plates and strips, incomplete removal of residual water, etc., and achieve improvement Cleaning effect, controllable drying effect, and improved air jet uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

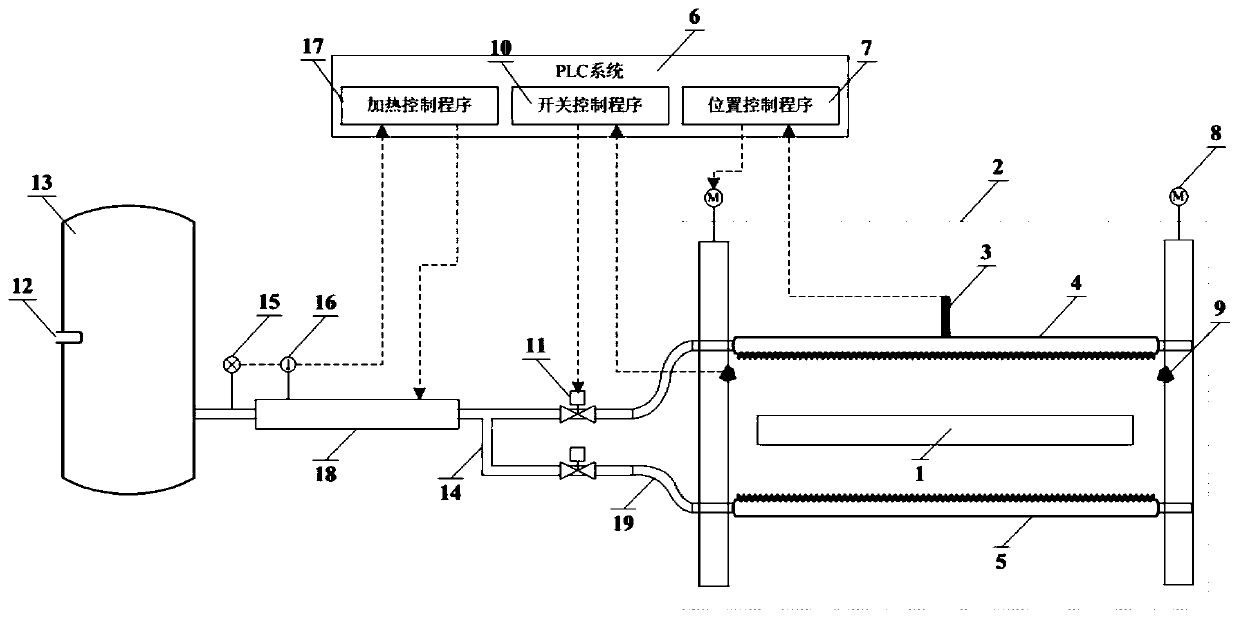

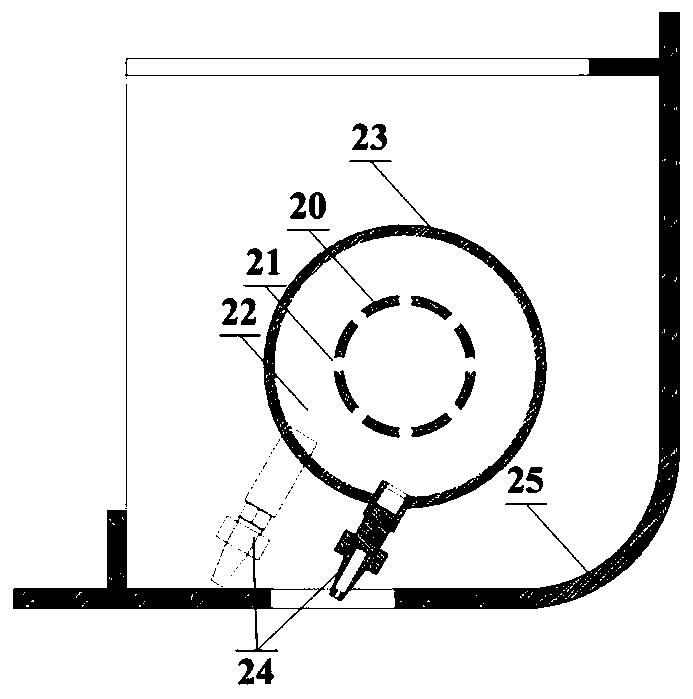

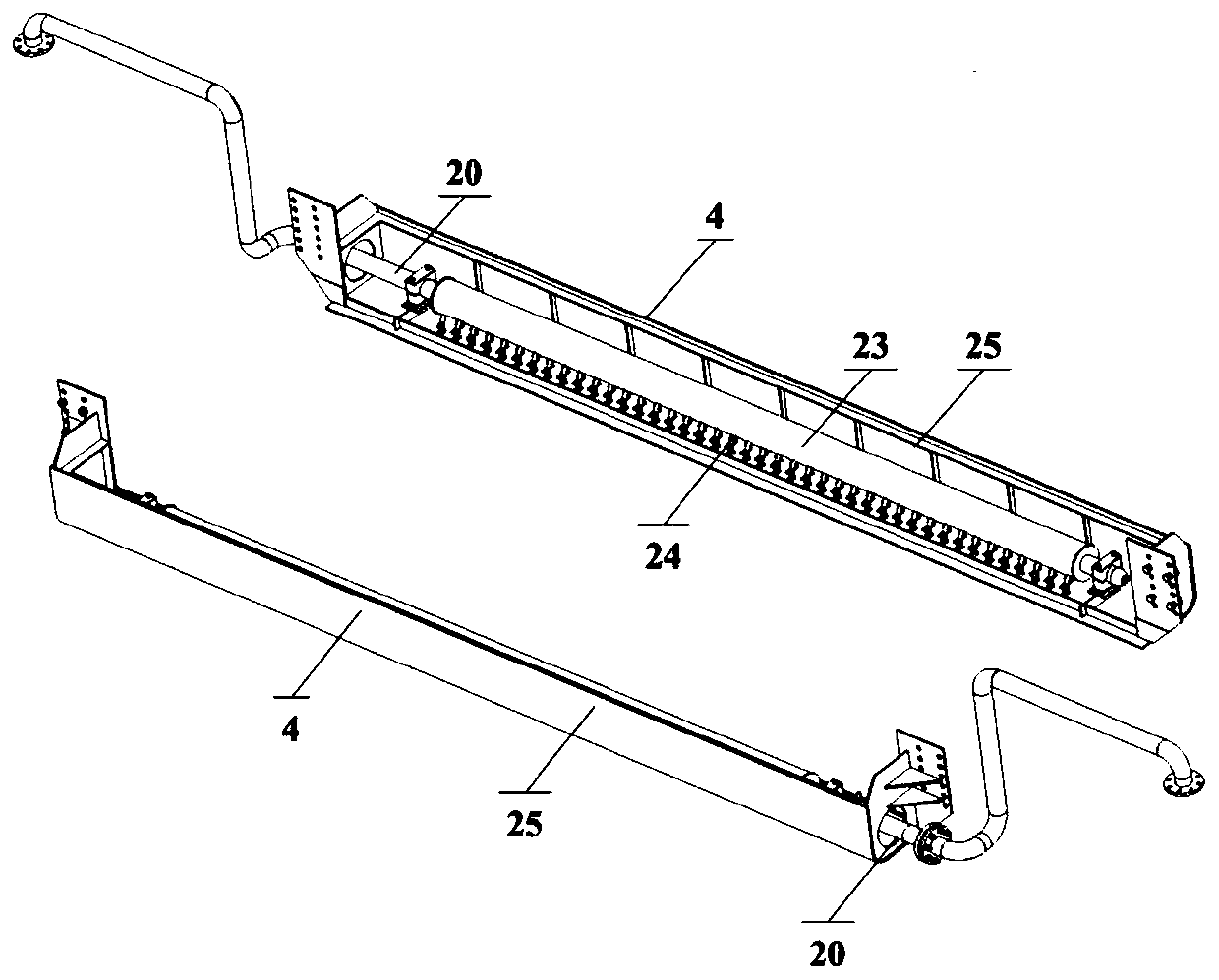

[0025] This embodiment provides a specific implementation process of a metal plate and strip heat treatment purging device of the present invention, such as figure 1 , 2 As shown in Figure 3, an 80mm thick sheet metal strip is used as an example to illustrate the implementation process in detail. After the strip 1 enters the roller quenching machine 2, the position sensor 3 detects the actual positions of the upper purge nozzle 4 and the lower purge nozzle 5, and transmits the position signal to the PLC system 6, which is called according to the thickness of the strip 1 The position control program 7 controls the moving frame lifting motor 8 of the roller quencher, and adjusts the vertical distance between the upper purge nozzle 4 and the upper surface of the strip 1 and the vertical distance between the lower purging nozzle 5 and the lower surface of the strip 1 is 200mm. The laser detector 9 detects the head position of the strip 1 and the detection signal enters the PLC syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com