Method for recovering hydrochloric acid from germanium concentrate distillation waste liquid

A technology for recovering hydrochloric acid and germanium concentrate, which is applied in the field of germanium smelting and purification, can solve the problems of failure to recover useful components, waste of resources, and complicated neutralization process, so as to reduce the amount of slag, improve the working environment, and avoid the neutralization process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

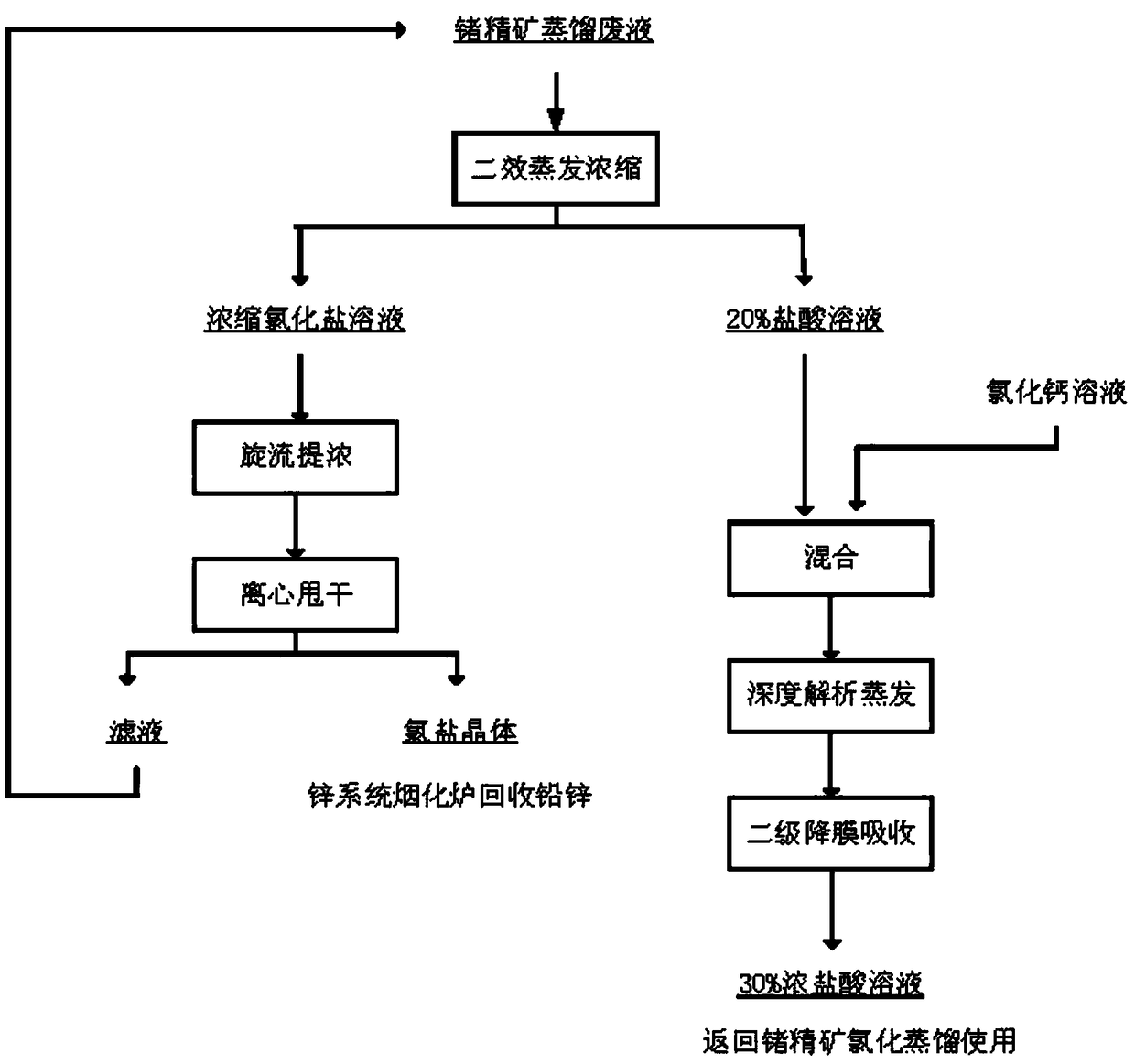

Image

Examples

Embodiment 1

[0019] will be 2m 3 The germanium concentrate distillation waste liquid with hydrochloric acid content of 20%, zinc chloride content of 78.5g / L, ferric chloride content of 19.6g / L, and lead chloride content of 6.8g / L is measured by a three-stage preheater through the feed pump After being heated and concentrated by the two-effect evaporating separator, more than 20% of the hydrochloric acid solution condensed by evaporation is discharged to the dilute acid collection tank for collection, and the concentrated salt solution is concentrated by swirling and then centrifuged to dry to obtain zinc chloride, 1.1kg of crystalline products such as lead chloride, sent to the zinc smelting process to recover lead and zinc from the fuming furnace; 20% hydrochloric acid is transported to the deep analysis tower through the hydrochloric acid pump and mixed with calcium chloride solution. After mixing, the concentration of calcium chloride is 160g / L , in the depth analysis tower, the hydroch...

Embodiment 2

[0021] will be 2m 3 The germanium concentrate distillation waste liquid with a hydrochloric acid content of 20.1%, a zinc chloride content of 85g / L, a ferric chloride content of 23.2g / L and a lead chloride content of 10.5g / L is metered by a feed pump using a three-stage preheater and then passed through The two-effect evaporative separator is heated and concentrated, and the hydrochloric acid solution of more than 20% evaporated and condensed is discharged to the dilute acid collection tank for collection. The concentrated salt solution is concentrated by swirling and then centrifuged to dry to obtain zinc chloride, ferric chloride, and chlorine. 1.18kg of crystalline products such as lead chloride, sent to the zinc smelting process to recover lead and zinc from the fuming furnace; 20% hydrochloric acid is transported to the deep analysis tower through the hydrochloric acid pump and mixed with calcium chloride solution. After mixing, the concentration of calcium chloride is 200...

Embodiment 3

[0023] will be 2m 3 The germanium concentrate distillation waste liquid with hydrochloric acid content of 20.2%, zinc chloride content of 90.5g / L, ferric chloride content of 25.2g / L and lead chloride content of 12.7g / L is measured by a three-stage preheater through the feed pump After being heated and concentrated by the two-effect evaporating separator, more than 20% of the hydrochloric acid solution condensed by evaporation is discharged to the dilute acid collection tank for collection, and the concentrated salt solution is concentrated by swirling and then centrifuged to dry to obtain zinc chloride, 1.21kg of crystalline products such as lead chloride, sent to the zinc smelting process to recover lead and zinc from the fuming furnace; 20% concentration of hydrochloric acid is transported to the deep analysis tower through the hydrochloric acid pump and mixed with calcium chloride solution. After mixing, the concentration of calcium chloride is 250g / L , in the depth analysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com