High-entropy alloy and multi-component carbide eutectic composite material and in-situ preparation method

A technology for high-entropy alloys and composite materials, applied in the field of high-entropy alloys and multi-component carbide eutectic composite materials and their in-situ preparation, to achieve clean phase interfaces, reduce grain size, and good high temperature creep resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

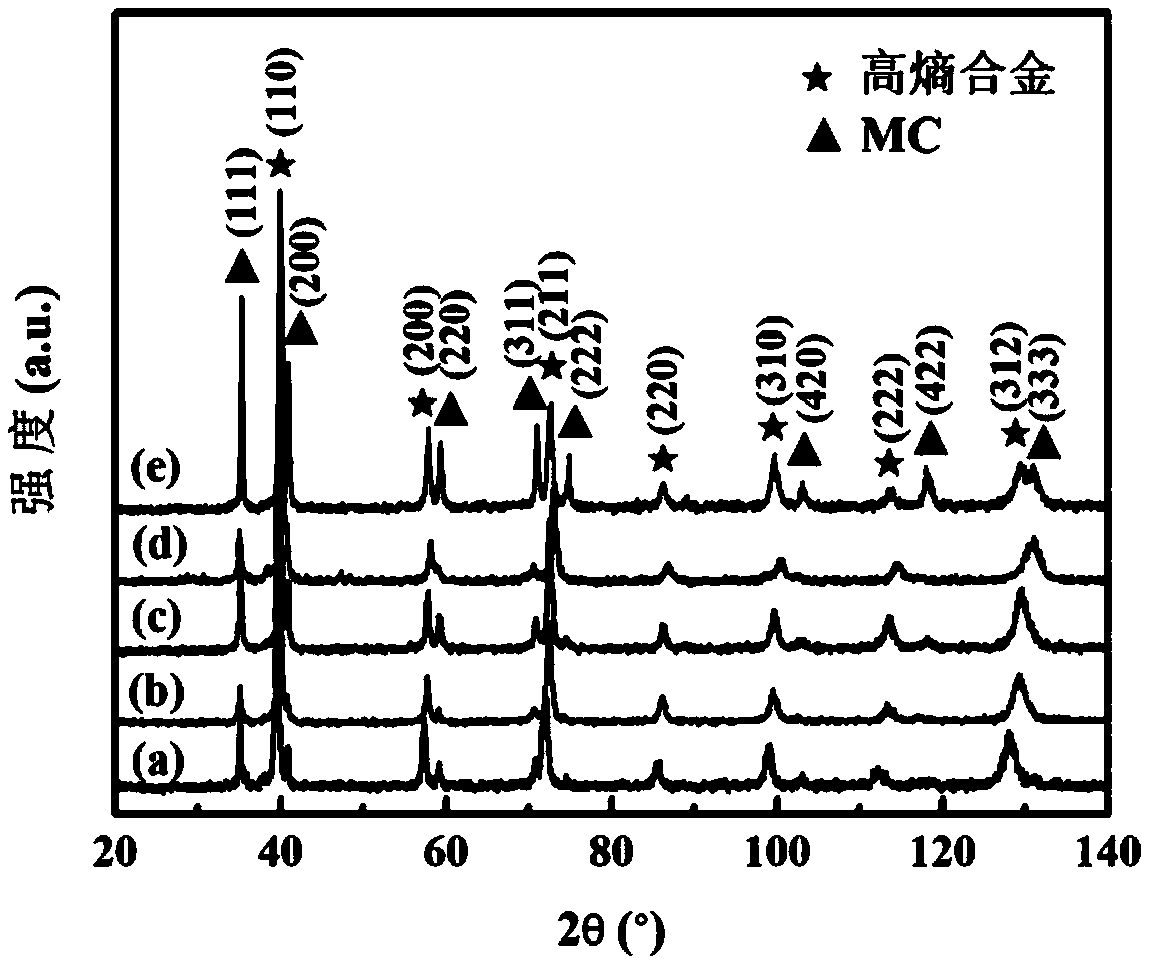

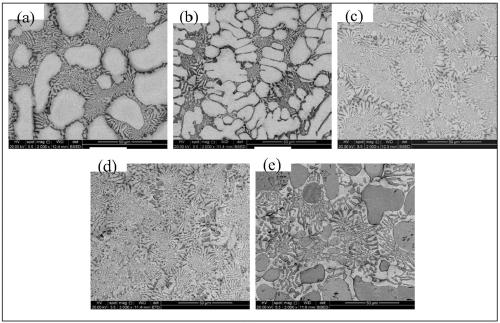

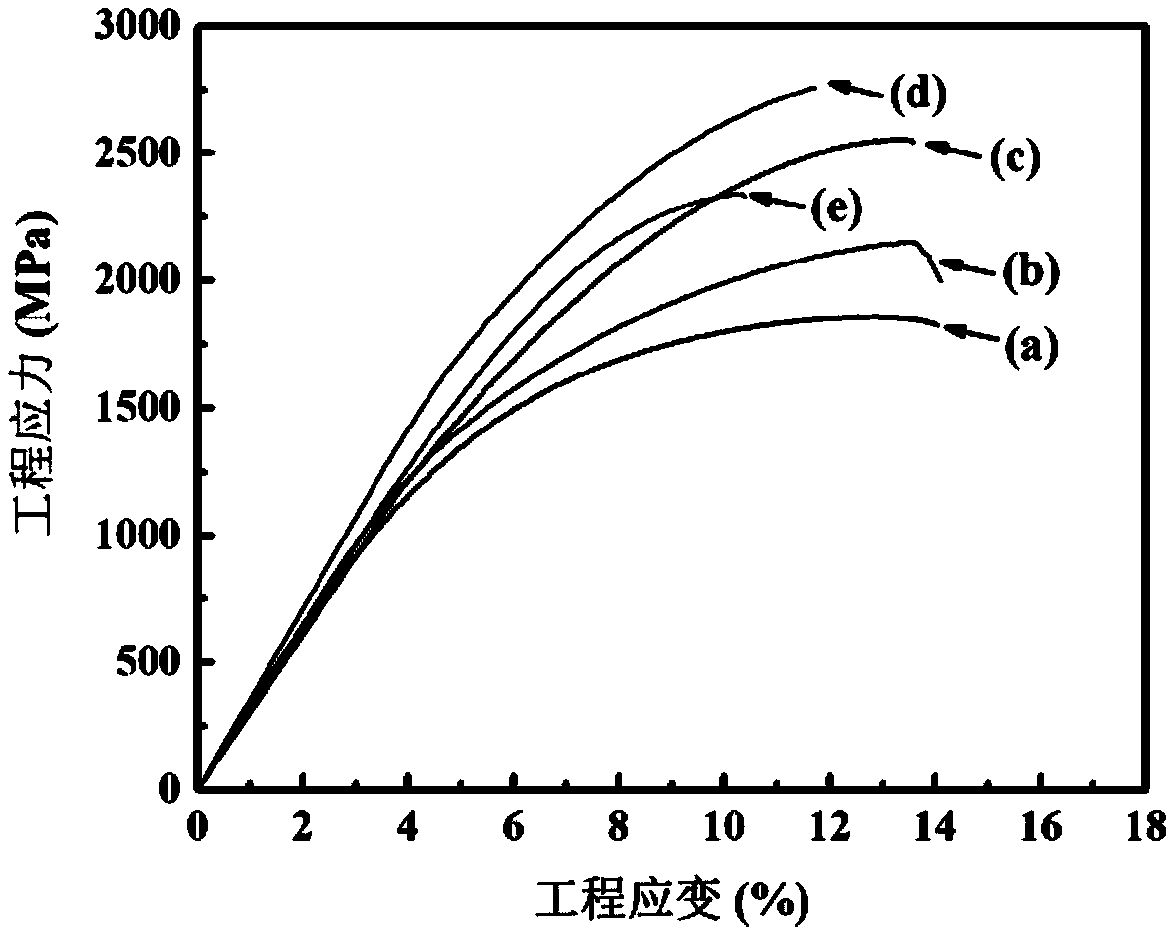

Embodiment 1

[0028] Preparation of MoNbW(TaC) 0.5 composite material. The specific steps are as follows:

[0029] (1) Mixing: Weigh 2.5935g of Mo powder, 2.5116g of Nb powder, 4.9750g of W powder, and 2.6080g of TaC powder with a purity of 99.95% (Mo / Nb / W / TaC molar ratio is 1:1:1:0.5 ), the particle size of the powder is 20 μm; use a light ball mill for 15 hours to mix evenly to obtain a mixed powder.

[0030] (2) Preparation of prefabricated block: put the mixed powder obtained in step 1 into a WC mold, and perform cold high-pressure molding (pressure 300 MPa) with a tablet press for 10 minutes to obtain a prefabricated block.

[0031] (3) Preparation of composite materials by electric arc melting: close the furnace door to vacuumize, and then pass 99.999% high-purity argon gas to make the pressure in the furnace relative to the standard atmospheric pressure reach -0.01MPa, start the arc quickly, and adjust the output power Melting to 40%-60% (current: 200-300A) for 2 minutes. After t...

Embodiment 2

[0034] Preparation of Re 0.5 MoNbW(TaC) 0.5 composite material. The specific steps are as follows:

[0035] (1) Weighing: Weigh 2.5140g of Re powder, 2.4638g of Mo powder, 2.6372g of Nb powder, 4.975g of W powder, and 2.6080g of TaC powder with a purity of 99.9% (Re / Mo / Nb / W / TaC molar ratio is 0.5:0.95:1.05:1:0.5). The particle size of the powder is 5 μm; it is mixed uniformly by using a light ball mill for 20 hours to obtain a mixed powder.

[0036] (2) Preparation of prefabricated block: put the mixed powder obtained in step 1 into a WC mould, and perform cold high-pressure molding (pressure 250 MPa) with a tablet press for 8 minutes to obtain a prefabricated block.

[0037] (3) Preparation of composite materials by electric arc melting: close the furnace door to vacuumize, and then pass 99.999% high-purity argon gas to make the pressure in the furnace relative to the standard atmospheric pressure reach -0.01MPa, start the arc quickly, and adjust the output power Melting...

Embodiment 3

[0040] Preparation of Re 0.5 MoNbW(TaC) 0.9 composite material. The specific steps are as follows:

[0041] (1) Mixing: take by weighing 2.5140g of Re powder, 2.5935g of Mo powder, 2.5116g of Nb powder, 4.9750g of W powder, 4.6943g of TaC powder (Re / Mo / Nb / W / TaC molar ratio is 0.5:1:1:1:0.9), the particle size of Re powder, Nb powder and TaC powder is 44 μm, and the particle size of other powders is 0.5 μm; use a light ball mill to mix evenly for 25 hours to obtain a mixed powder.

[0042] (2) Preparation of prefabricated block: put the mixed powder obtained in step 1 into a WC mould, and perform cold high-pressure molding (pressure 300 MPa) with a tablet press for 6 minutes to obtain a prefabricated block.

[0043] (3) Preparation of composite materials by electric arc melting: close the furnace door to vacuumize, and then pass 99.999% high-purity argon gas to make the pressure in the furnace relative to the standard atmospheric pressure reach -0.01MPa, start the arc quickl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com