Sponge pavement and preparation method thereof

A technology of sponge and concrete, applied in the direction of roads, roads, ceramic products, etc., can solve the problems of insufficient strength of permeable concrete, poor water permeability, surface photocatalyst catalytic efficiency and poor long-term performance, etc., to avoid the weakening of water permeability and mechanical properties , high water permeability and strong mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

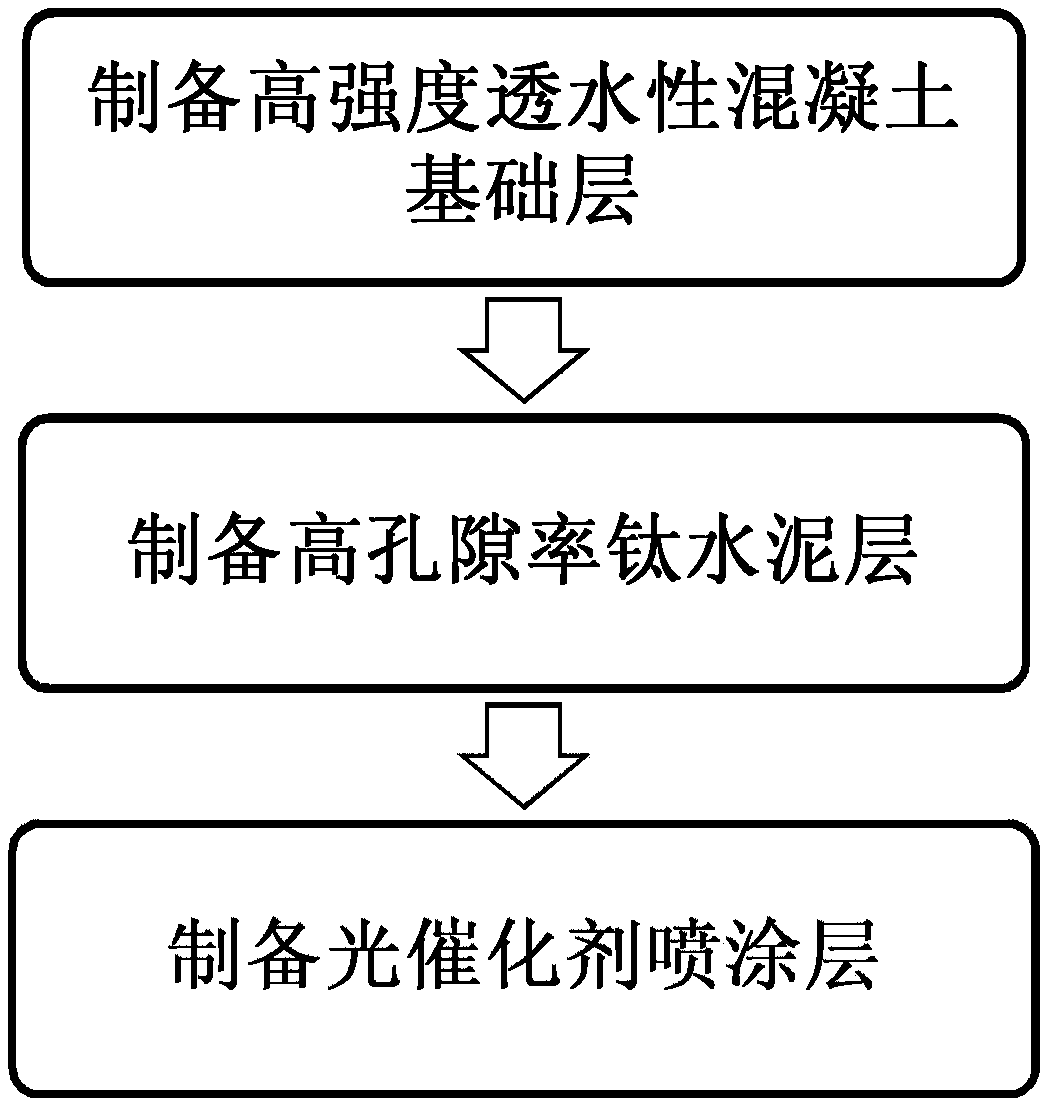

[0023] Specifically, the preparation method of sponge pavement of the present invention comprises the following steps:

[0024] Step S1, preparing a water-permeable concrete base layer; the water-permeable concrete base layer can be formed into a firm water-permeable base layer by using conventional techniques such as portland cement and sandstone aggregates, or can be further improved by the method of the present invention to increase Structural strength.

[0025] Preferably, the permeable concrete base layer in step S1 is prepared by the following method:

[0026] First mix the aggregate with a particle size of 4-15mm, Portland cement with a strength grade of 42.5 and fibers with a length of 6-20mm, and add some water and water reducer during the mixing process;

[0027] Then add the silicate-titanium salt slurry and stir again to form the permeable concrete base layer;

[0028] Wherein, the preparation method of described silicate-titanium salt slurry is:

[0029] Using ...

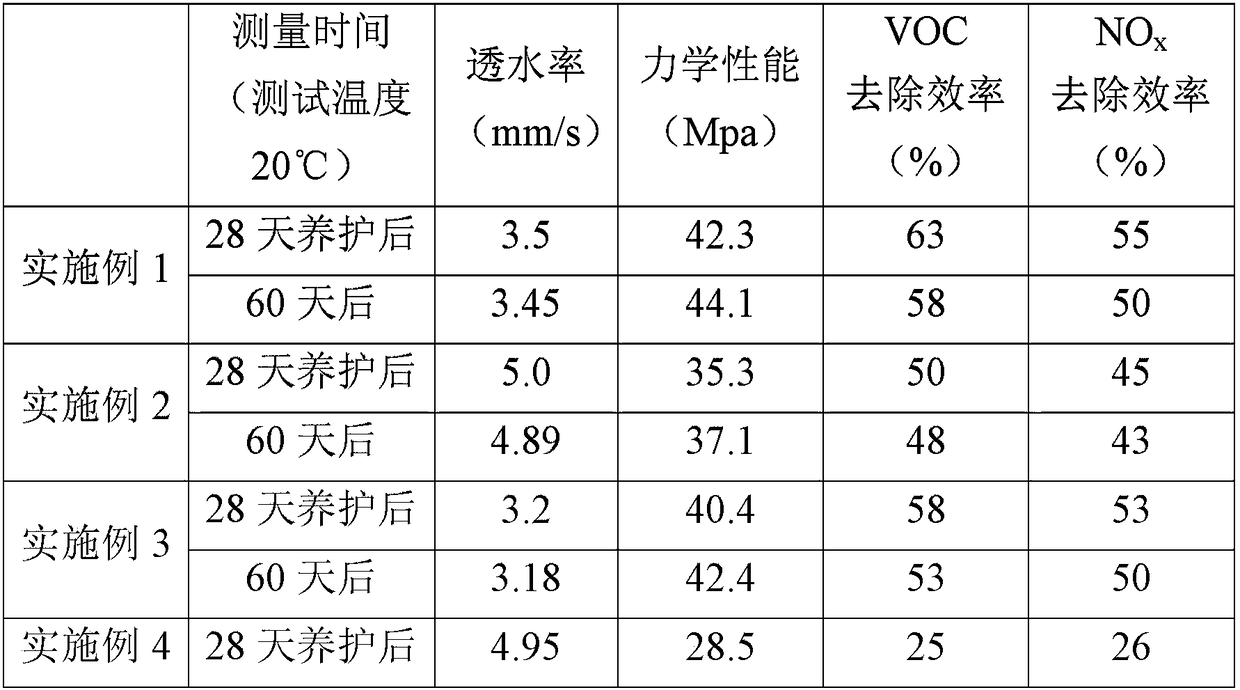

Embodiment 1

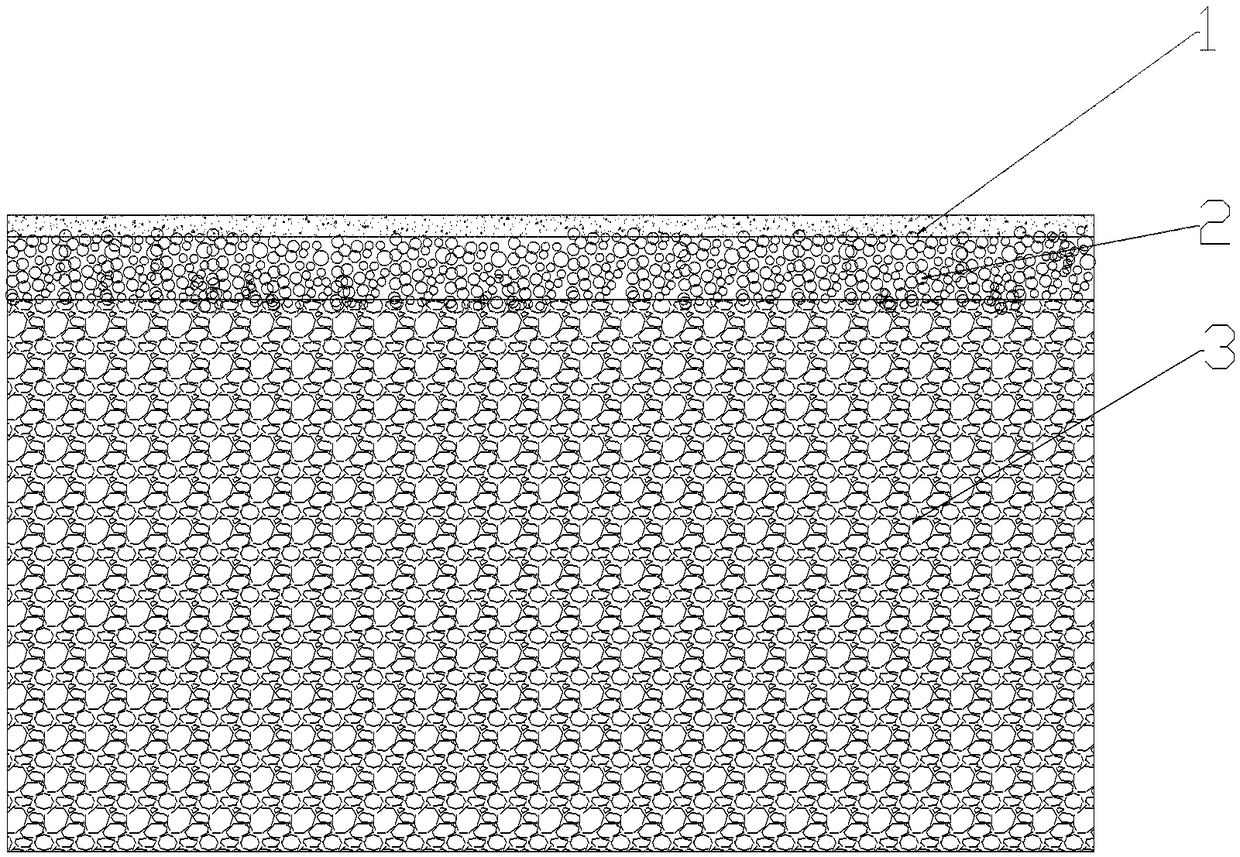

[0058] Such as figure 1 , 2 Shown, the preparation process and formula of the sponge pavement of the present embodiment are as follows:

[0059] The first step is to prepare the base layer of permeable concrete 3

[0060] At room temperature, first mix the basalt crushed stone aggregate with Portland cement with a strength grade of 42.5 and glass fiber, and gradually add water and HG-FDN water reducer during the stirring process. Then add silicate-titanium salt slurry composed of sodium silicate and titanium nitrate, and then fully stir to form a permeable concrete base layer 3 .

[0061] The silicate-titanium salt slurry is prepared by using titanium nitrate as a titanium dioxide precursor, sodium hexametaphosphate as a dispersant, and sodium silicate as a silicate, and is formed by adding water and stirring.

[0062] The mass fractions of various raw materials for preparing the permeable concrete base layer 3 are: Portland cement 16.54%, basalt gravel 73.32%, HG-FDN type ...

Embodiment 2

[0068] Such as figure 1 , 2 Shown, the preparation process and formula of the sponge pavement of the present embodiment are as follows:

[0069] The first step is to prepare the base layer of permeable concrete 3

[0070] At room temperature, first mix the granite crushed stone aggregate with Portland cement with a strength grade of 42.5 and glass fiber, and gradually add water and ordinary water reducer during the stirring process. Then add the silicate-titanium salt slurry composed of sodium metasilicate and titanium sulfate, and then fully stir to form the permeable concrete base layer 3 .

[0071] The silicate-titanium salt slurry is prepared by using titanium sulfate as a titanium dioxide precursor, sodium hexametaphosphate as a dispersant, and sodium metasilicate as a silicate, and is formed by adding water and stirring.

[0072] The mass fractions of various raw materials for preparing the permeable concrete base layer 3 are: 15.47% of Portland cement, 76.72% of gran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com