A non-plated terminal electrode silver paste for inductors

A terminal electrode and silver paste technology, applied in transformers/inductor coils/windings/connections, conductive materials dispersed in non-conductive inorganic materials, etc., can solve problems such as pollution, and achieve high electrode activity and electrode solderability Good, good solderability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

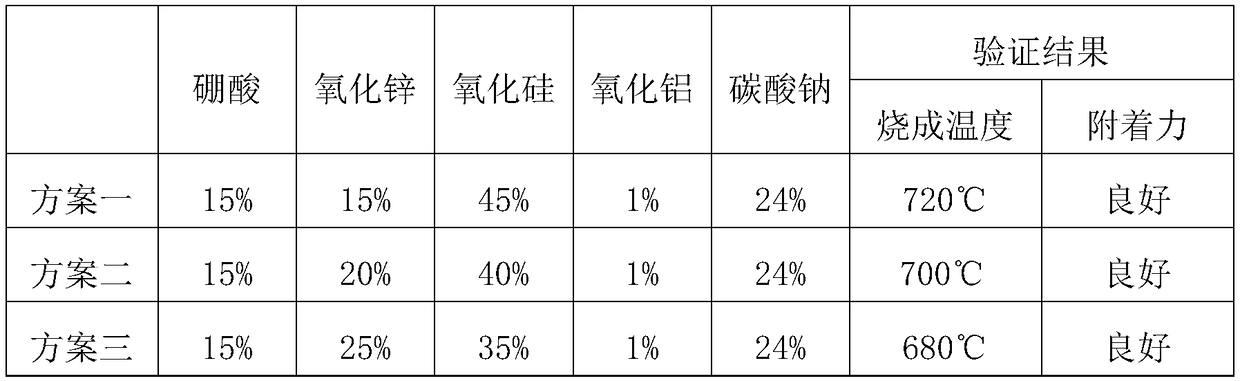

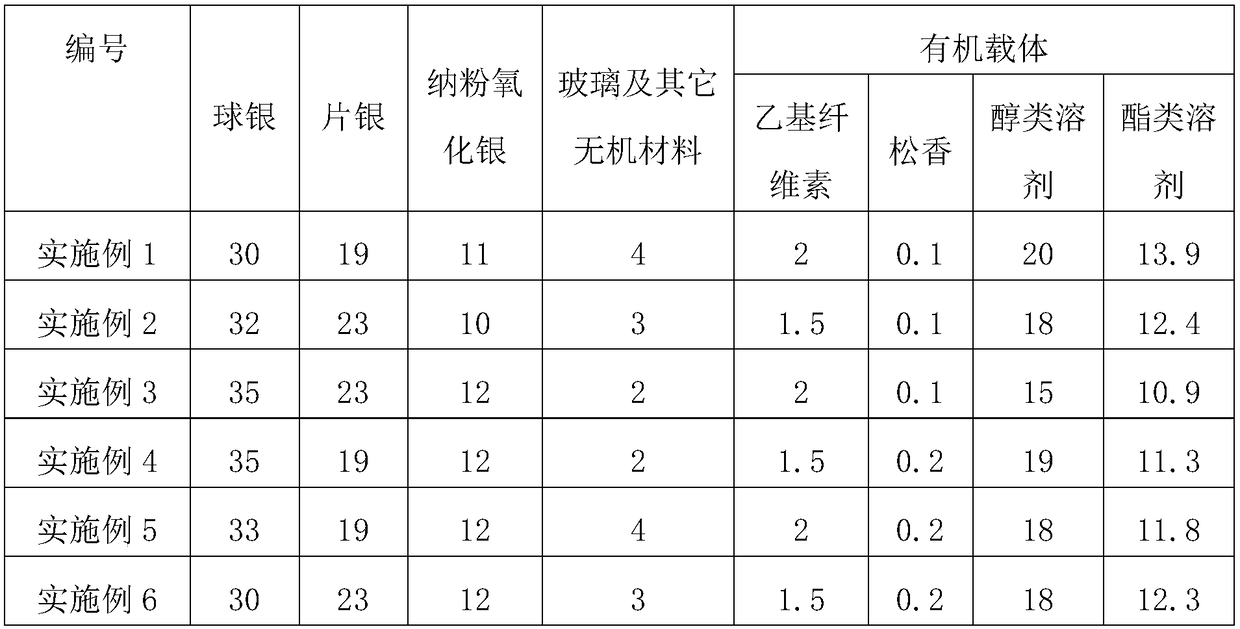

[0008] The gist of the present invention is to use spherical silver with extremely high sphericity to match flake silver powder, dope a certain proportion of nano-silver oxide powder, use borosilicate glass powder and other inorganic additive materials, and a reasonable ratio of organic carrier to select a suitable Particle size, to obtain terminal electrode silver paste with good appearance quality, excellent electrical performance, no plating and environmental protection. The inductance products produced by using the terminal electrode silver paste meet the jumper requirements in the SMT packaging process. The electroplating-free terminal electrode silver paste for inductors of the present invention: 1. The self-developed organic carrier is used to provide the paste with good rheological properties and a strong drying strength; 2. The electrode paste is made by our company The combination of spherical silver powder and flake silver powder is developed to provide a good thixo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com