A kind of preparation method of vanadium selenide doped selenium material

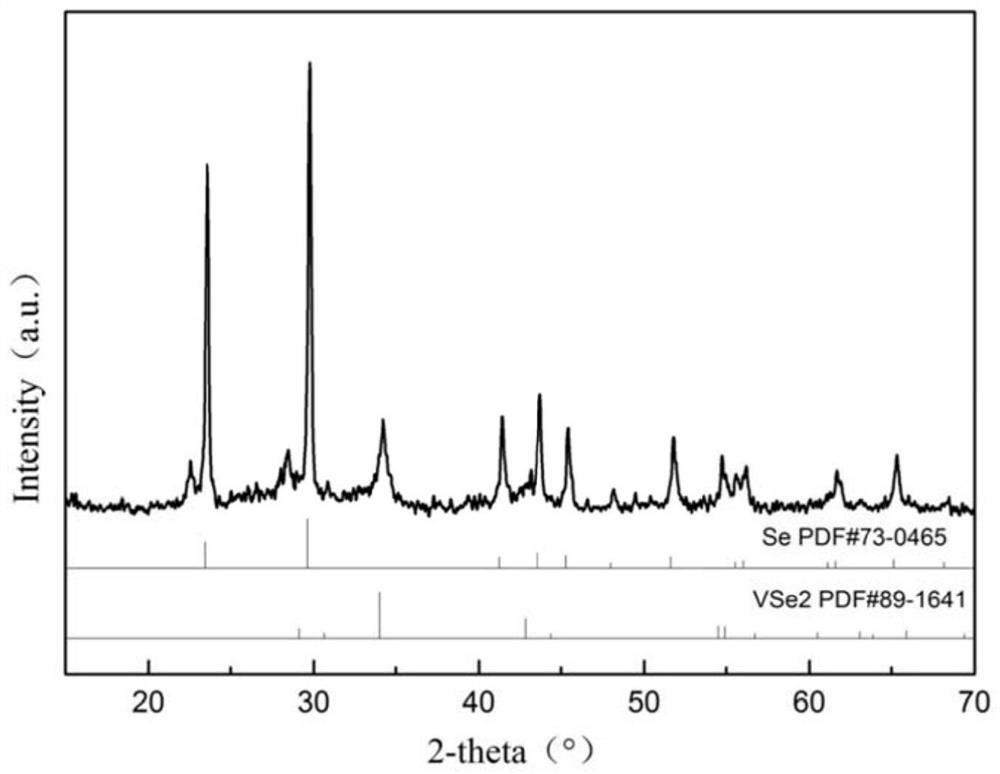

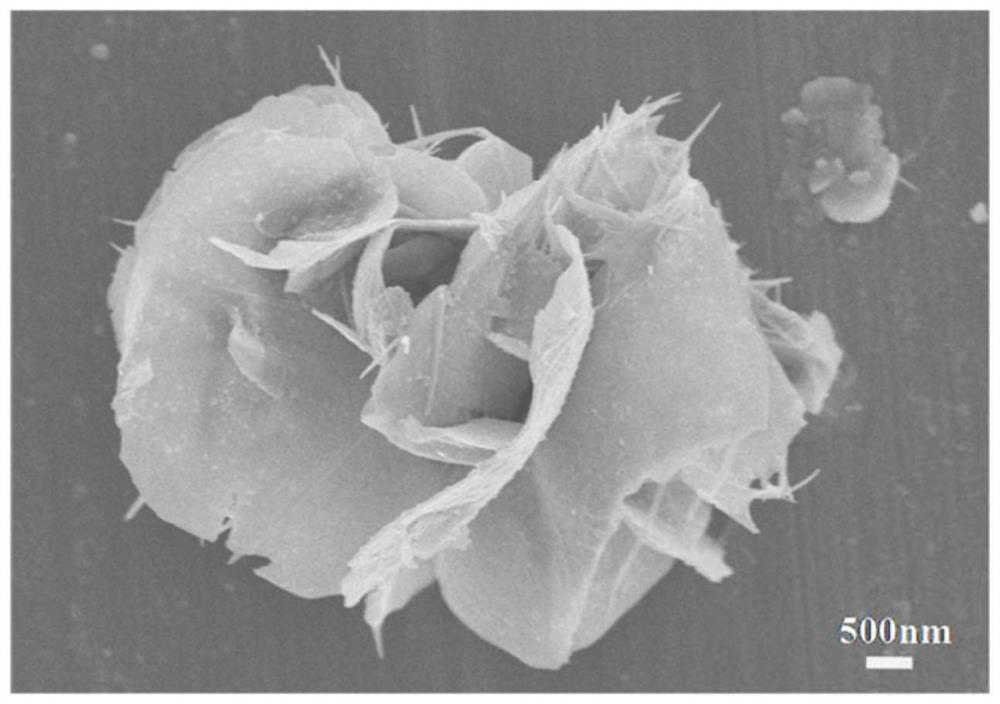

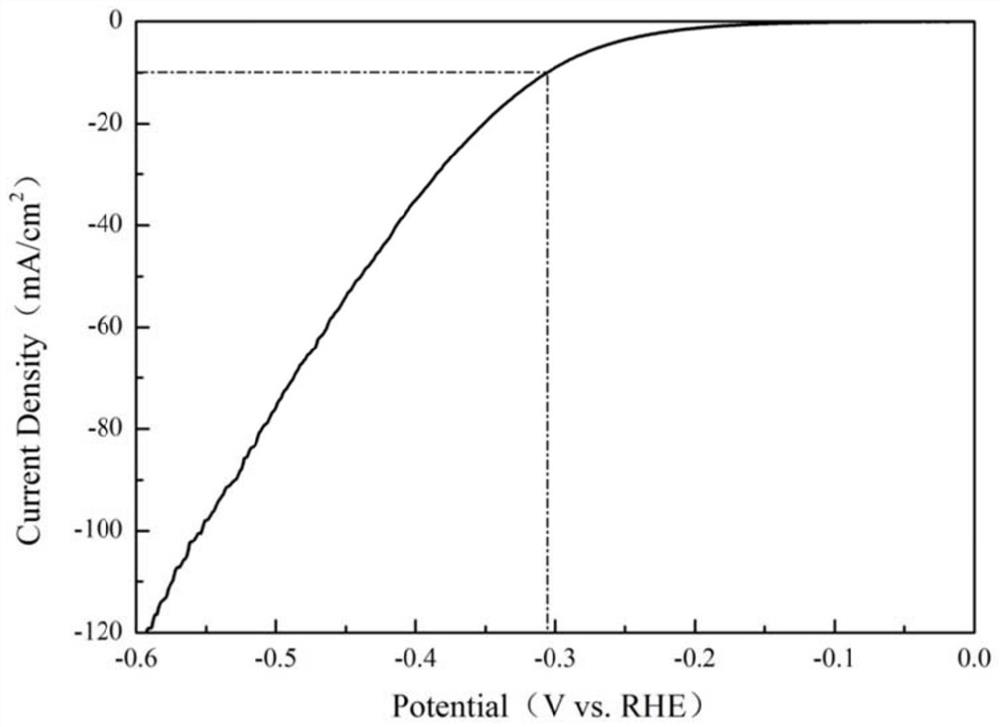

A technology of vanadium selenide and composite materials, which is applied in the field of preparation of vanadium selenide doped with selenium materials, can solve the problems of limited application and lack of band gap in graphene, and achieve fast electron transfer rate, good electrocatalytic performance and low production cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) First, weigh 0.976g of NaBH 4 , dissolve it in 20mL of deionized water, add 0.834g of selenium powder, and stir magnetically for 40min to obtain a clear NaHSe solution. The prepared solution is slowly poured into 10mL of absolute ethanol under nitrogen flow to obtain mixture;

[0032] 2) Transfer the mixed solution obtained in step 1) to a polytetrafluoroethylene-lined high-pressure reactor, and weigh ammonium metavanadate according to V(mol):Se(mol)=1:2 and add it to the reactor , control the filling ratio of the solution in the reactor at 40%, seal the reactor, place it in an oven and react at 120°C for 10h;

[0033] 3) After the reaction is finished, wash with deionized water and absolute ethanol for 5 times, then vacuum dry and grind to obtain the precursor;

[0034] 4) Put the precursor obtained in step 3) into a magnetic boat, and place it in a low-temperature tube furnace, and pump the inside of the low-temperature tube furnace tube into a vacuum environment...

Embodiment 2

[0041] 1) First, weigh 1.085g of NaBH 4 , dissolve it in 20mL of deionized water, add 0.957g of selenium powder, and stir magnetically for 40min to obtain a clear NaHSe solution. Slowly pour the prepared above solution into 10mL of absolute ethanol under nitrogen flow to obtain mixture;

[0042]2) Transfer the mixed solution obtained in step 1) to a polytetrafluoroethylene-lined high-pressure reactor, and weigh ammonium metavanadate according to V(mol):Se(mol)=1.5:2 and add it to the reactor , control the filling ratio of the solution in the reactor at 50%, seal the reactor, place it in an oven and react at 150°C for 8 hours;

[0043] 3) After the reaction is finished, wash with deionized water and absolute ethanol for 5 times, then vacuum dry and grind to obtain the precursor;

[0044] 4) Put the precursor obtained in step 3) into a magnetic boat, and place it in a low-temperature tube furnace, and pump the inside of the low-temperature tube furnace tube into a vacuum envir...

Embodiment 3

[0048] 1) First, weigh 1.031g of NaBH 4 , dissolve it in 20mL of deionized water, add 0.896g of selenium powder, and stir magnetically for 40min to obtain a clear NaHSe solution. The prepared solution is slowly poured into 10mL of absolute ethanol under nitrogen flow to obtain mixture;

[0049] 2) Transfer the mixed solution obtained in step 1) to a polytetrafluoroethylene-lined high-pressure reactor, and weigh ammonium metavanadate according to V(mol):Se(mol)=1.3:2 and add it to the reactor , control the filling ratio of the solution in the reactor at 60%, seal the reactor, place it in an oven and react at 140°C for 9 hours;

[0050] 3) After the reaction is finished, wash with deionized water and absolute ethanol for 5 times, then vacuum dry and grind to obtain the precursor;

[0051] 4) Put the precursor obtained in step 3) into a magnetic boat, and place it in a low-temperature tube furnace, and pump the inside of the low-temperature tube furnace tube into a vacuum envir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com