Method for directly preparing 4N level strontium chloride

A strontium chloride, direct technology, applied in chemical instruments and methods, calcium/strontium/barium chloride, inorganic chemistry, etc., can solve the problems such as the preparation of 4N grade strontium chloride, etc., to achieve less reagent consumption, product The effect of high purity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

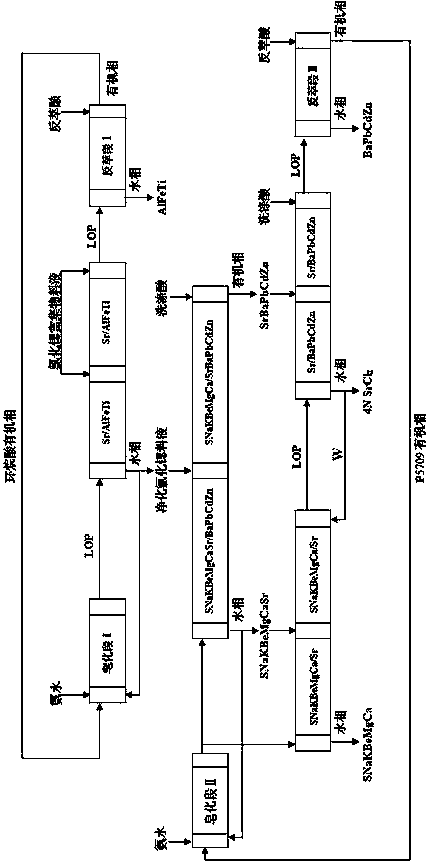

Image

Examples

Embodiment 1

[0034] The naphthenic acid organic phase is a kerosene solution of naphthenic acid and TBP, in which the concentration of naphthenic acid is 1.0 mol / L and the concentration of TBP is 0.1 mol / L.

[0035] The organic phase of P5709 is a kerosene solution of P5709, and the concentration of P5709 is 1.0 mol / L.

[0036] The concentration of related elements in the strontium chloride enrichment solution are: S 4.5g / L, Na 2.0g / L, K 0.030g / L, Be 0.50g / L, Mg 1.5g / L, Ca 3.0g / L , Sr 115.0g / L, Ba 2.0g / L, Pb 0.50g / L, Cd 0.030g / L, Zn 0.50g / L, Al 0.030g / L, Fe 0.50g / L, Ti 0.050g / L.

[0037] Step 1: Saponification section I

[0038] According to the molar ratio of naphthenic acid: ammonia: strontium = 1: 0.60: 0.30, the naphthenic acid organic phase, 6.0 mol / L ammonia and the Sr / AlFeTi fractionation extraction and separation system from step 2 of the first stage outlet water phase The raw strontium chloride feed solution is added to the first stage of the saponification tank. After 8 levels of co-fl...

Embodiment 2

[0055] The naphthenic acid organic phase is a kerosene solution of naphthenic acid and TBP, in which the concentration of naphthenic acid is 1.0 mol / L and the concentration of TBP is 0.1 mol / L.

[0056] The organic phase of P5709 is a kerosene solution of P5709, and the concentration of P5709 is 1.0 mol / L.

[0057] The concentration of related elements in the strontium chloride enrichment solution are: S 1.0g / L, Na 0.10g / L, K 0.010g / L, Be 0.10g / L, Mg 0.10g / L, Ca 1.0g / L , Sr 150.0g / L, Ba 1.0g / L, Pb 0.010g / L, Cd0.010g / L, Zn 0.10g / L, Al 0.10g / L, Fe 0.10g / L, Ti 0.010g / L.

[0058] Step 1: Saponification section I

[0059] According to the molar ratio of naphthenic acid: ammonia: strontium = 1: 0.60: 0.30, the naphthenic acid organic phase, 6.0 mol / L ammonia and the Sr / AlFeTi fractionation extraction and separation system from step 2 of the first stage outlet water phase The raw strontium chloride feed solution is added to the first stage of the saponification tank. After 8 levels of co-f...

Embodiment 3

[0076] The naphthenic acid organic phase is a kerosene solution of naphthenic acid and TBP, in which the concentration of naphthenic acid is 1.0 mol / L and the concentration of TBP is 0.1 mol / L.

[0077] The organic phase of P5709 is a kerosene solution of P5709, and the concentration of P5709 is 1.0 mol / L.

[0078] The concentration of relevant elements in the strontium chloride enrichment solution are: S 8.0g / L, Na 4.0g / L, K 0.050g / L, Be 1.0g / L, Mg 3.0g / L, Ca 5.0g / L , Sr 80.0g / L, Ba 3.0g / L, Pb 1.0g / L, Cd 0.050g / L, Zn1.0g / L, Al 1.0g / L, Fe 1.0g / L, Ti 0.10g / L.

[0079] Step 1: Saponification section I

[0080] According to the molar ratio of naphthenic acid: ammonia: strontium = 1: 0.60: 0.30, the naphthenic acid organic phase, 6.0 mol / L ammonia and the Sr / AlFeTi fractionation extraction and separation system from step 2 of the first stage outlet water phase The raw strontium chloride feed solution is added to the first stage of the saponification tank. After 8 levels of co-flow sapon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com