Antifouling metal membrane module filter based on microelectric structure and water purification method thereof

A metal film, component technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

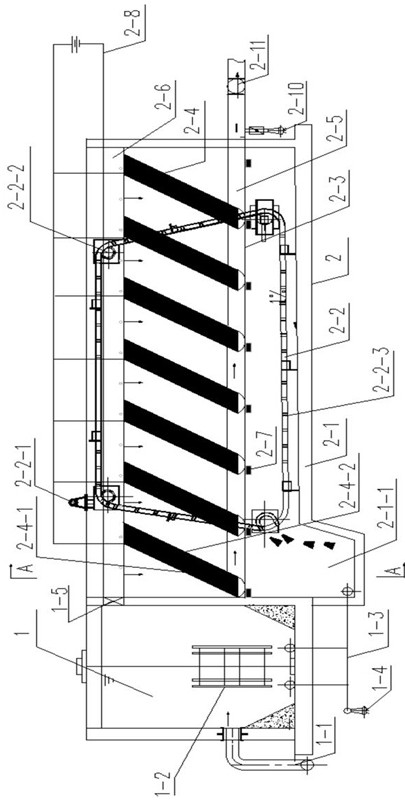

[0046] Specific implementation mode one: combine figure 1 The antifouling metal membrane module filter based on the microelectric structure of the present invention is described. In this embodiment, the anti-pollution metal membrane module filter based on the microelectric structure is composed of a flocculation adjustment tank 1, a metal membrane separation tank 2 and a backwashing system. Clean water and discharge sludge from the bottom; the backwashing process starts after the filtration process stops, and adopts the operation mode from the back to the front, the backwashing water pump enters water, and the front sludge pump drains water.

specific Embodiment approach 2

[0047] Specific implementation mode two: combination figure 1 To illustrate the flocculation homogeneity method of the present invention, the flocculation regulating tank 1 is located at the front end of the metal membrane separation tank 2 . The flocculation regulating tank 1 includes a sewage inlet pipe 1-1, a stirring paddle 1-2, a sludge discharge pipe 1-3, a sludge pump 1-4 and an overflow hole 1-5, wherein:

[0048] The sewage inlet pipe 1-1 is arranged on the front wall of the flocculation adjustment tank 1;

[0049] The overflow holes 1-5 are arranged on the top of the rear wall of the flocculation adjustment tank 1;

[0050] The stirring paddle 1-2 is arranged inside the flocculation regulating tank 1;

[0051] The mud discharge pipe 1-3 is arranged at the bottom of the flocculation regulating tank 1;

[0052] The sludge pump 1-4 is connected with the sludge discharge pipe 1-3.

[0053]The sewage enters the flocculation adjustment tank 1 from the sewage inlet pipe...

specific Embodiment approach 3

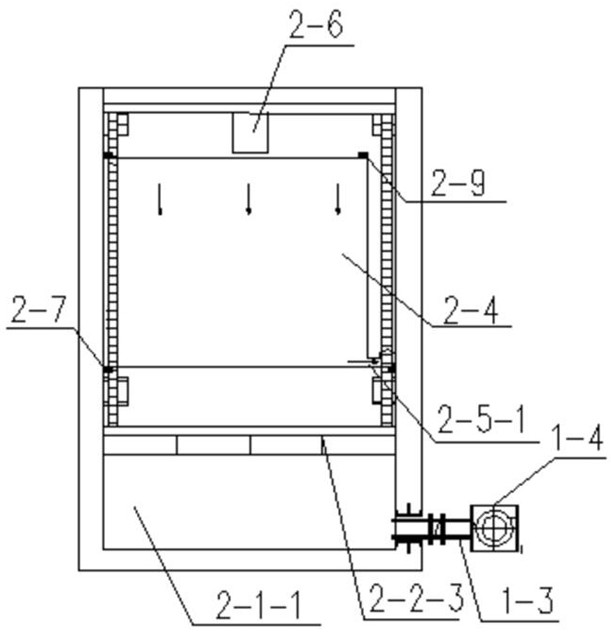

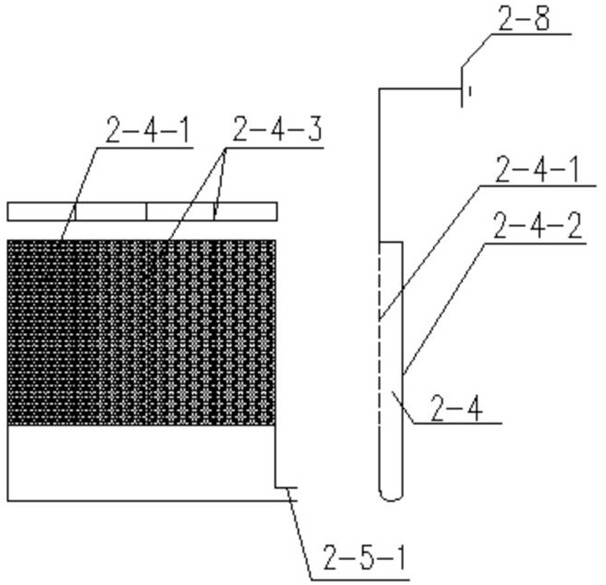

[0054] Specific implementation mode three: combination Figure 1-4 To illustrate the particle pollutant separation method of the present invention, the rear end of the flocculation adjustment tank 1 is a metal membrane separation tank 2, and the metal membrane separation tank 2 is connected to the flocculation adjustment tank 1 through overflow holes 1-5. The metal membrane separation tank 2 includes a tank body 2-1, a chain type mud scraper 2-2, a support beam 2-3, a metal membrane module 2-4, a clear water collection main pipe 2-5, and a water inlet perforated water tank 2 -6. Support horns 2-7, external power supply 2-8 and fixed I-beam 2-9, wherein:

[0055] The tank body 2-1 is rectangular, and the bottom of its front end is provided with a trapezoidal sludge pit 2-1-1 connected to the sludge discharge pipe 1-3, which is used to collect the sludge from the tank body 2-2 from the chain type mud scraper 2-2. 1 The sludge scraped from the bottom is discharged through the sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com