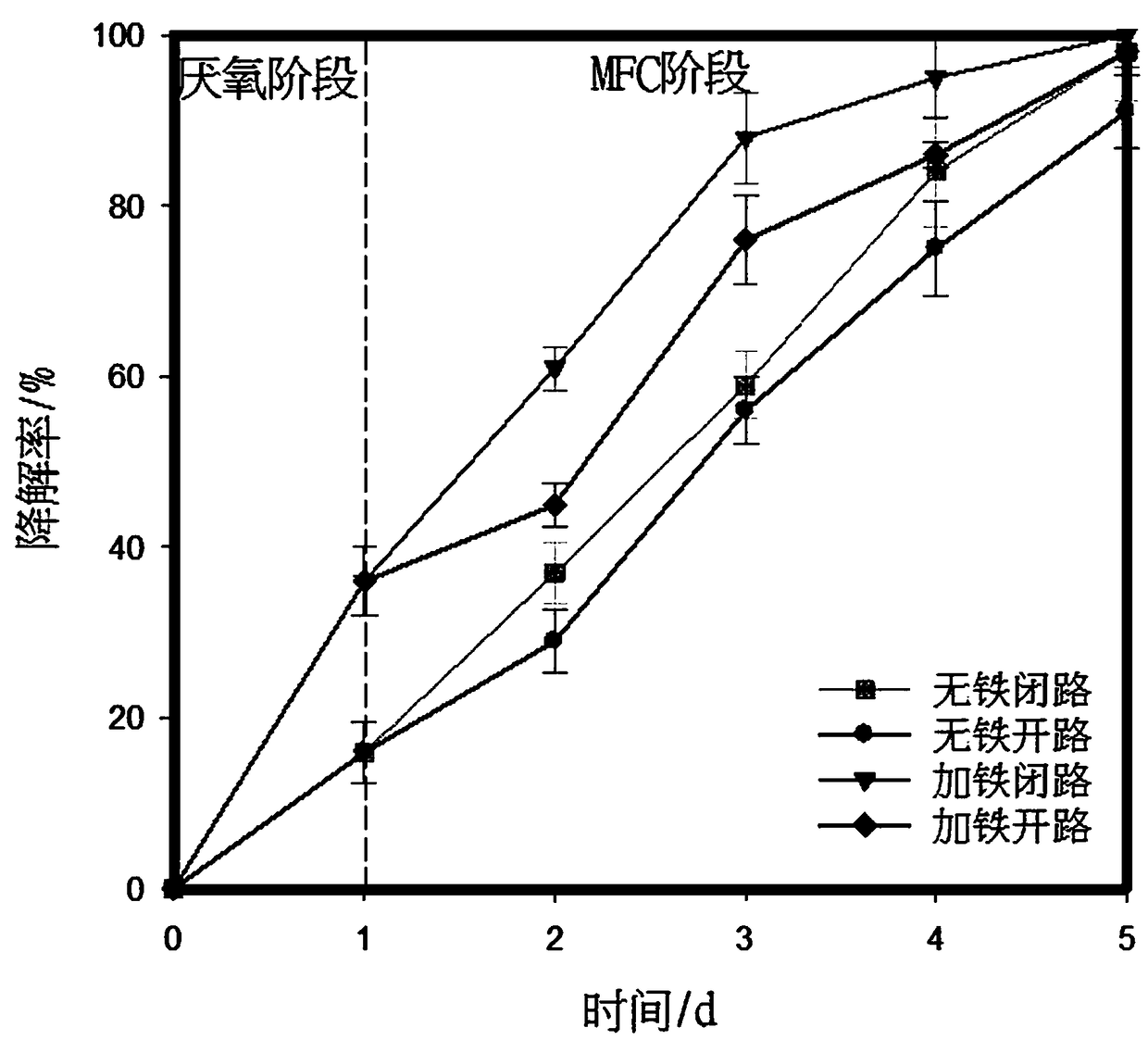

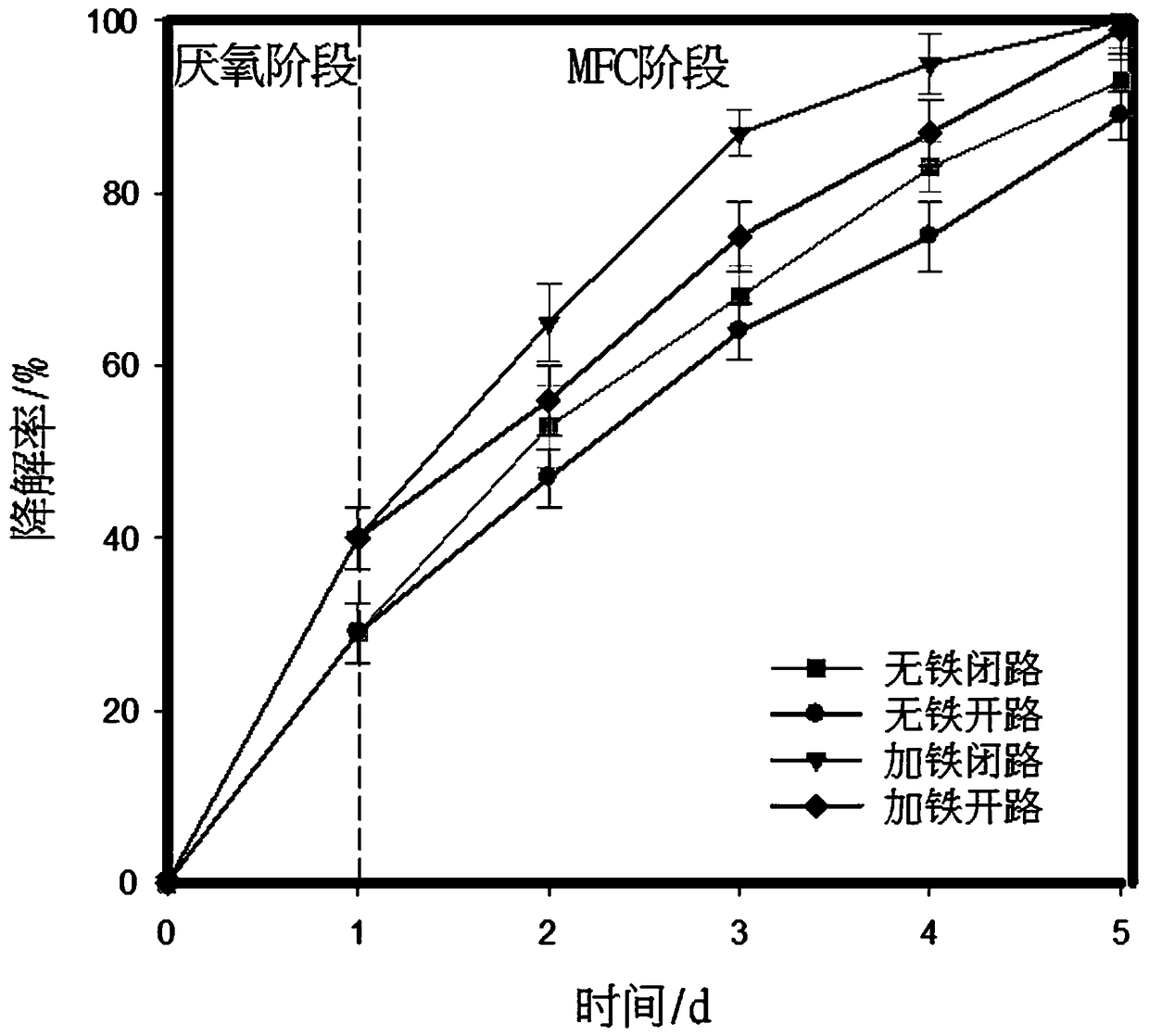

Method for utilizing zero-valent iron to reinforce microbial fuel cell for degrading typical nitrogen-contained heterocyclic compounds

A technology of nitrogen heterocyclic compounds and fuel cells, applied in chemical instruments and methods, electrochemical biological combination treatment, biological water/sewage treatment, etc., can solve the problems of increasing the difficulty and cost of treatment, difficult to remove, etc., and achieve faster Degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] 1. Treatment of microbial fuel cell materials: Take a 3cm carbon brush, wash it with deionized water first, then soak it in acetone for 24 hours, put it in a muffle furnace, burn it at 600°C for 30 minutes, and finally place it in deionized water spare. The proton exchange membrane was soaked in saturated NaCl solution for 24 hours, and then rinsed with deionized water before use.

[0025] 2. Assembly and connection of the microbial fuel cell device: the volume of the cathode and anode is 28mL, and they are made of plexiglass. The treated carbon brushes are inserted into the cathode and anode as electrodes respectively, and the anode and cathode chambers are separated by a proton exchange membrane. The external circuit is connected to the carbon brushes inserted into the anode and cathode via wires to form a circuit, and an external resistance of 1 000Ω is connected. The current data changes of the reactor are recorded in real time by a data recorder (keithley2700).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com