Preparation method of ceramic artware

A technology of ceramic handicrafts and toners, which is applied in clay products, applications, household appliances, etc., can solve the problems of affecting the appreciation value of porcelain, insufficient surface gloss, complicated preparation methods, etc., to achieve improved cold and heat resistance, smooth surface, uniform color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

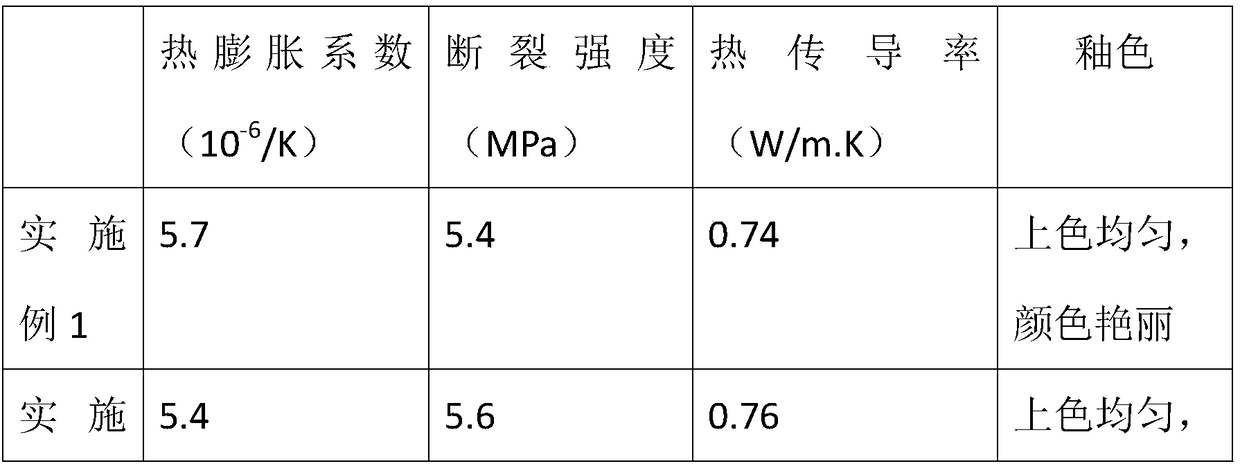

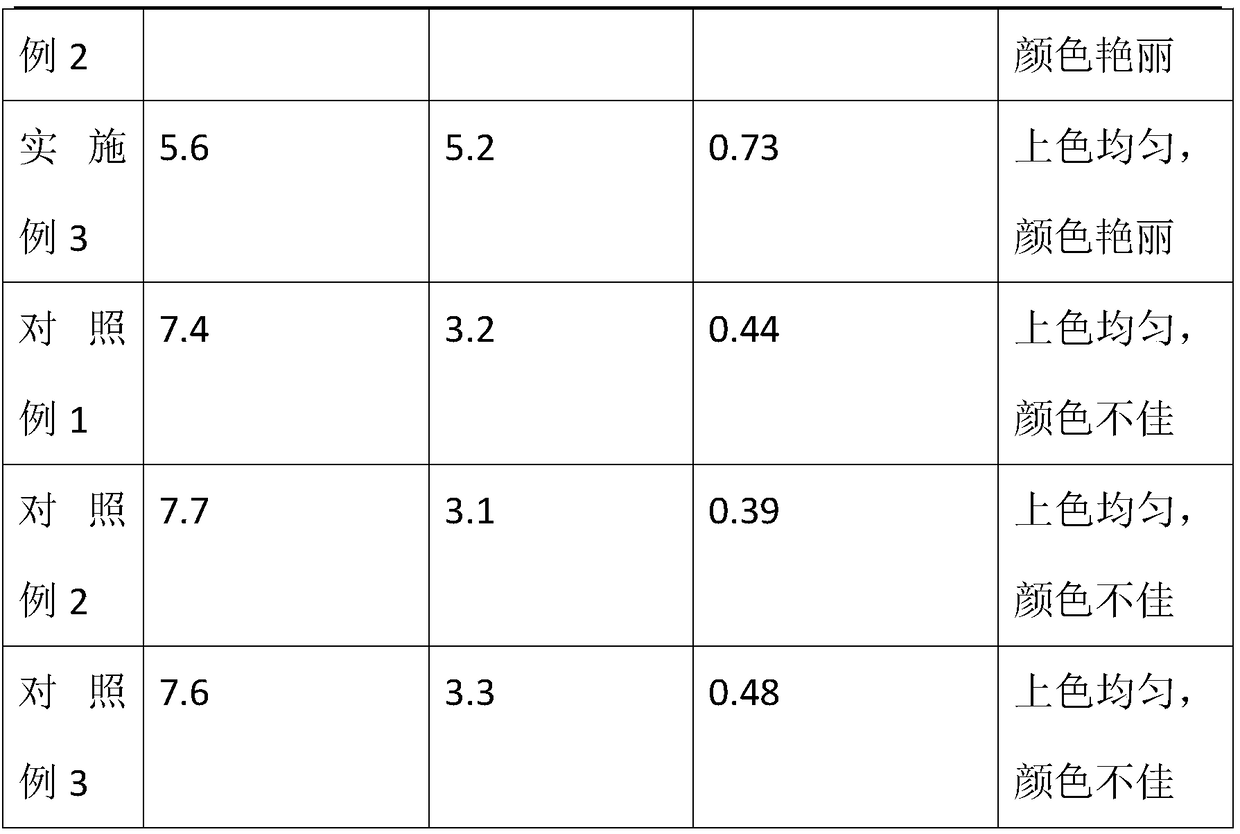

Examples

Embodiment 1

[0016] 1) Toner preparation: 20 parts of potassium dichromate, 5 parts of calcium oxide, 8 parts of calcium carbonate, nano silicon oxide (particle size 20nm, specific surface area 160m 2 / g) 20 parts, 4 parts of medical stone, mix well and then grind finely, add 2 parts of maleic anhydride grafted polypropylene, 1 part of calcium fluoride and mix evenly, put into the kiln for calcination in the temperature range of 1000 ℃, calcine After crushing, rinsing to yellow water, further processing and grinding, extruding and granulating with an extruder under vacuum, the temperature of the extruder is 180°C, after completing the granulation, crush and grind to obtain a color agent;

[0017] 2) Prepare the glaze: weigh 10% of the colorant and 90% of the lime glaze obtained in step 1), dilute the colorant and lime glaze, mix them evenly and pass through a 500-mesh sieve to obtain the glaze;

[0018] 3) Soak the bisque-fired ceramic handicraft in the soaking solution for 1 hour, air-dry...

Embodiment 2

[0021] 1) Toner preparation: 21 parts of potassium dichromate, 6 parts of calcium oxide, 9 parts of calcium carbonate, nano silicon oxide (particle size 23nm, specific surface area 165m 2 / g) 25 parts, 5 parts of medical stone, mixed evenly and ground, add 3 parts of maleic anhydride grafted polypropylene, 1.5 parts of calcium fluoride, mix evenly, put into the kiln for calcination in the temperature range of 1100 ℃, calcined After crushing, rinsing to yellow water, further processing and grinding, extruding and granulating with an extruder under vacuum, the temperature of the extruder is 190°C, after completing the granulation, crush and grind to obtain a color agent;

[0022] 2) Prepare the glaze: weigh 13% of the colorant and 87% of the lime glaze obtained in step 1), dilute the colorant and lime glaze, mix them evenly and pass through a 500-mesh sieve to obtain the glaze;

[0023] 3) Soak the bisque-fired ceramic handicraft in the soaking liquid for 1.5 hours, air-dry it n...

Embodiment 3

[0026] 1) Toner preparation: 22 parts of potassium dichromate, 7 parts of calcium oxide, 10 parts of calcium carbonate, nano silicon oxide (particle size 26nm, specific surface area 170m 2 / g) 30 parts, 6 parts of medical stone, mix well and grind finely, add 4 parts of maleic anhydride grafted polypropylene, 2 parts of calcium fluoride and mix evenly, put into the kiln for calcination in the temperature range of 1200 ℃, calcine After crushing, rinsing to yellow water, further processing and grinding, extruding and granulating with an extruder under vacuum, the temperature of the extruder is 200°C, after completing the granulation, crush and grind to obtain a color agent;

[0027] 2) Prepare the glaze: weigh 16% of the colorant and 84% of the lime glaze obtained in step 1), dilute the colorant and lime glaze, mix them evenly and pass through a 500-mesh sieve to obtain the glaze;

[0028] 3) Soak the bisque-fired ceramic handicraft in the soaking solution for 2 hours, air-dry i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com