A kind of cement mixture and its preparation process

A technology for mixing materials and cement clinker, applied in the field of cement production, can solve problems such as poor concrete strength, and achieve the effects of good stable structural strength, good bonding degree and good water absorption function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

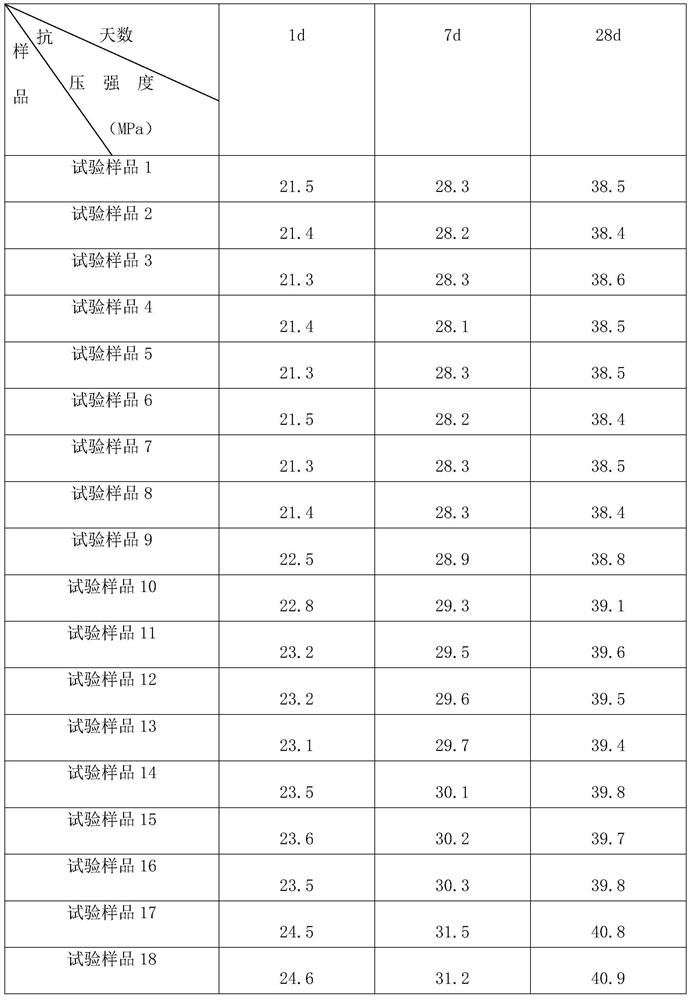

Examples

Embodiment 1

[0047] Embodiment 1: A kind of cement mixture, each component and its corresponding parts by weight are as shown in Table 1, and are prepared through the following steps:

[0048] Step 1, put cement clinker, fly ash, mineral powder, gypsum and silicon powder of corresponding parts by weight into the mixing tank for mixing, the stirring speed is 800rpm, and the stirring time is 30min to obtain the mixed material;

[0049] Step 2, mixing and stirring the bamboo fiber filaments and expanded perlite powder in corresponding parts by weight, the stirring speed is 600rpm, and the stirring time is 40min, to obtain the filling masterbatch;

[0050] Step 3, mixing and stirring the above-mentioned mixture and the filler masterbatch evenly at a stirring speed of 500 rpm and a stirring time of 60 minutes to obtain coarse cement material;

[0051] Step 4, the above-mentioned cement coarse material is transported into the roller press through the conveyor belt, and crushed under the action o...

Embodiment 2-8

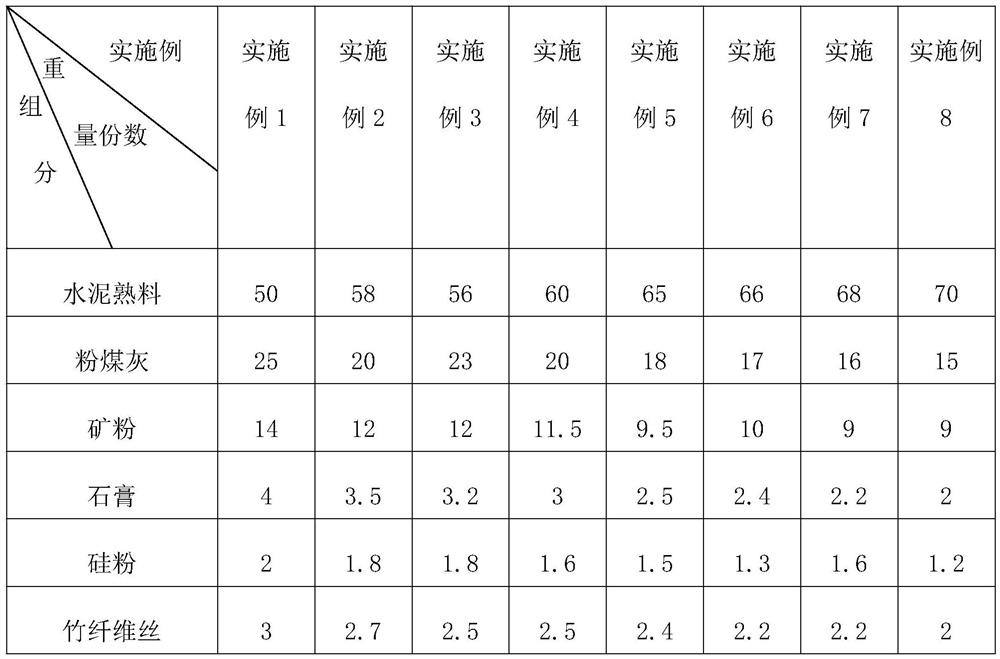

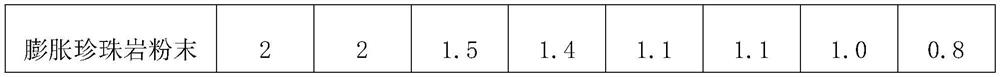

[0053] Example 2-8: A cement mixture, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0054] Each component and parts by weight thereof in table 1 embodiment 1-8

[0055]

[0056]

Embodiment 9

[0057] Embodiment 9: a kind of cement mixture, the difference with embodiment 1 is that described bamboo fiber silk carries out pretreatment, and the step of pretreatment is as follows:

[0058] Step a, place the bamboo fiber silk of the corresponding mass fraction in the alkaline solution, and add the polypropylene fiber of the corresponding mass fraction, stir and mix together, stir for 30min, the whole process temperature is controlled at 30°C, and the stirring speed is 500rpm;

[0059] Step b, adding polyvinyl alcohol in corresponding parts by mass to the alkaline solution in step a, and performing ultrasonic treatment;

[0060] In step c, the alkaline solution in step b is removed, and the bamboo fiber filaments are dried to obtain pretreated bamboo fiber filaments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com