Self-leveling waterproof mortar as well as preparation method and application thereof

A waterproof mortar and self-leveling technology, which is applied in the direction of buildings, bridges, bridge parts, etc., can solve the problems of increasing freeze-thaw damage, unstable piers and abutments, and affecting driving safety, so as to reduce evaporation loss, improve waterproof performance, and avoid surface damage. crack effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

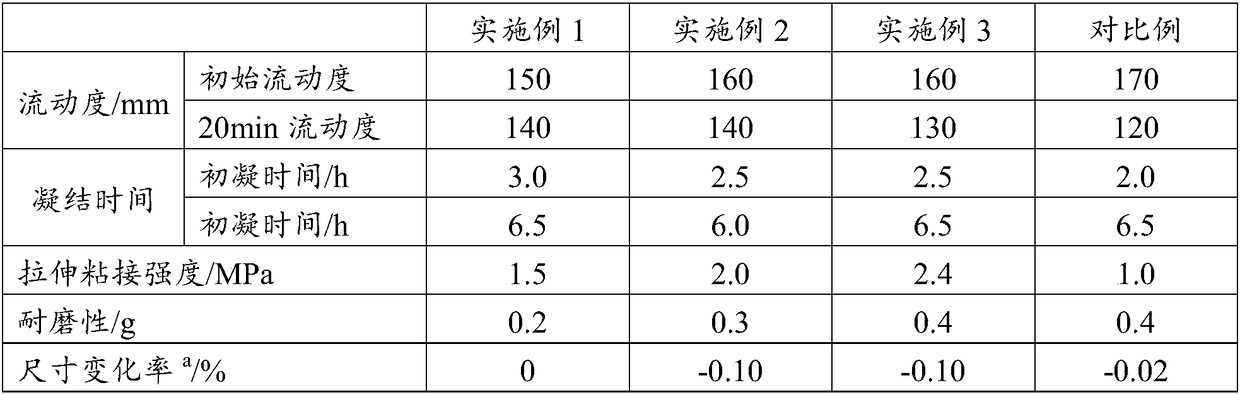

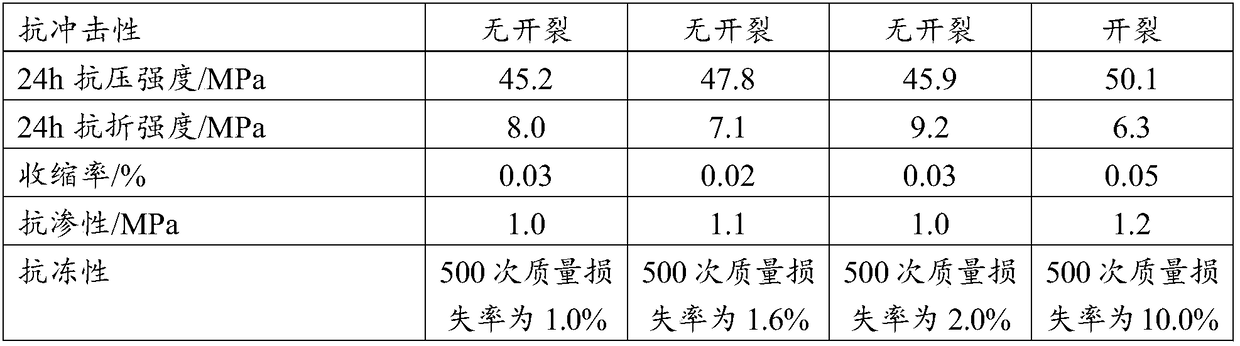

[0047] Example 1: A self-leveling waterproof mortar

[0048] The raw material composition of the self-leveling waterproof mortar described in this example is shown in Table 1; it was prepared by the following method:

[0049] A. Add the polymer emulsion, water, defoamer, water reducer, water-based epoxy resin emulsion, curing agent in the mixer in sequence and stir and mix evenly, the stirring speed is 20 ~ 40rpm;

[0050] B. Add the sand in the mass parts and stir and mix evenly, the stirring speed is 60~80rpm;

[0051] C. Then add the cement, mineral admixture, mineral filler, stabilizer in said mass parts in turn and stir and mix evenly, the stirring speed is 100~140rpm;

[0052] D. Stir again at a stirring speed of 100-140rpm for 3-5 minutes, then adjust the stirring speed to 20-40rpm and continue stirring for 1 minute.

Embodiment 2

[0053] Example 2: A self-leveling waterproof mortar

[0054] The raw material composition of the self-leveling waterproof mortar described in this example is shown in Table 1; it was prepared by the following method:

[0055] A. mix the cement, sand, mineral admixture, mineral filler and stabilizer of the mass parts to obtain dry powder;

[0056] B. Add the polymer emulsion, water, defoamer, water reducing agent, water-based epoxy resin emulsion, and curing agent in the mass parts into the mortar mixer in sequence, and stir at a slow speed, and the stirring speed is 20-40rpm;

[0057] C. Add the dry material prepared in step A', stir rapidly for 3-5 minutes at a stirring speed of 100-140 rpm, then adjust the stirring speed to 20-40 rpm and continue stirring for 1 minute to obtain the product.

Embodiment 3

[0058] Example 3: A self-leveling waterproof mortar

[0059] The raw material composition of the self-leveling waterproof mortar described in this example is shown in Table 1; the self-leveling waterproof mortar described in this example was prepared according to the same method and steps as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com