Method for promoting cis-trans isomerization of azobenzene derivative by utilizing black phosphorus nano-sheets

An azobenzene derivative, cis-trans isomerization technology, applied in organic chemistry methods, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of long operation cycle and complex methods, and achieve simple and easy operation. , the effect of accelerating the rate of cis-trans isomerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation steps of the present invention are as follows.

[0027] (1) Grind black phosphorus crystals into powder and mix uniformly in DMSO solvent. Argon was passed through the solution for 5 minutes, and then sealed with parafilm. Ultrasonic dispersion is carried out under water bath conditions, and the ultrasonic dispersion time is 4 to 8 hours. Finally, after centrifugation at 10,000 rpm, the supernatant was taken out for use.

[0028] (2) Mix the prepared above-mentioned black phosphorus supernatant with solutions of different azobenzene derivatives with a concentration of 0.0001~0.01mmol / L according to different volume ratios of 1~10, stir the mixed solution for 2 hours, and place under dark conditions Keep for 48 hours.

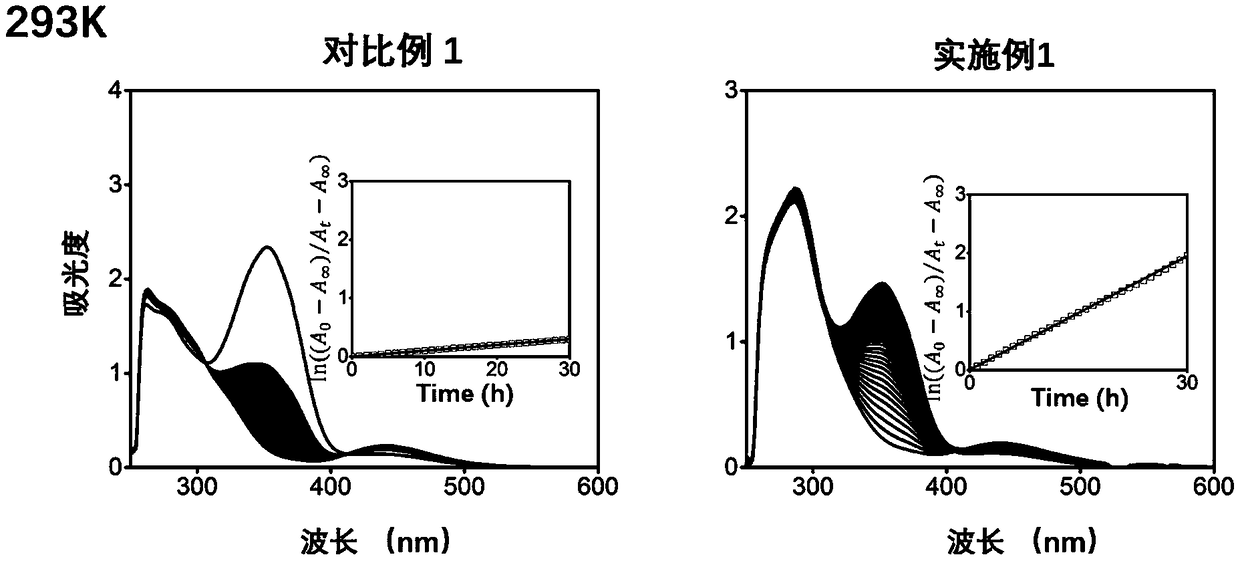

[0029] (3) The azobenzene mixed solution is irradiated with ultraviolet light with a wavelength of 365nm for 5 to 10 minutes to transform it into the Z configuration, and use the ultraviolet-visible spectrometer (Shimadzu UV-2600) and i...

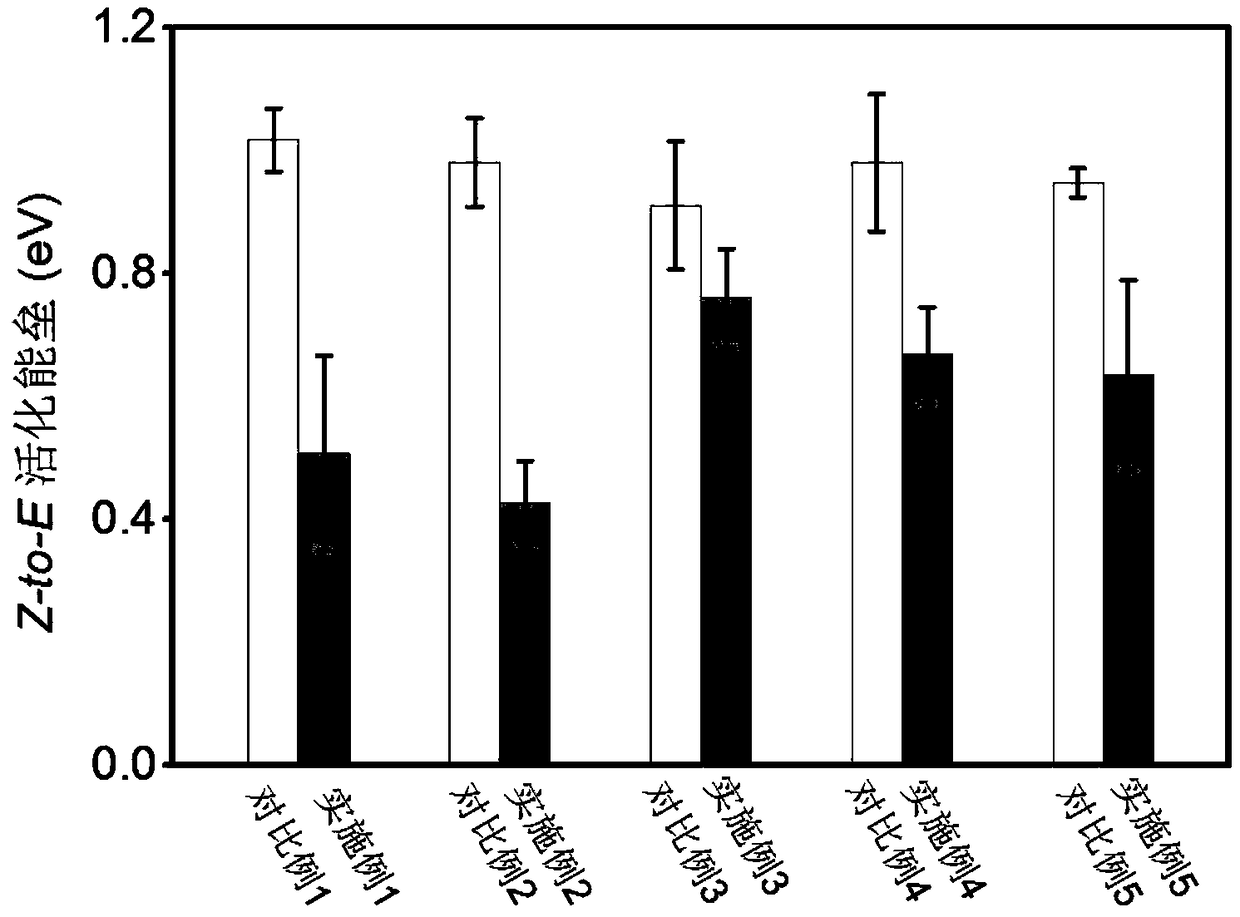

Embodiment 1

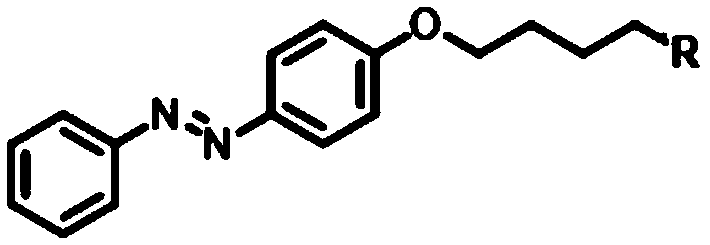

[0033] Put the black phosphorus powder into dimethyl sulfoxide (DMSO) solvent, put the DMSO solution of black phosphorus in the water bath under the condition of ultrasonic, ultrasonic for 8h, the temperature is controlled at 10-30°Centrifuge at the speed of 10000rpm after the ultrasonic , the centrifuged supernatant and the concentration of 0.0001mmol / L azobenzene derivative AB-OC 4 h 8 -NMe 3 + I - The DMSO solution was uniformly mixed with a volume ratio of 1:10, the mixed solution was stirred at room temperature for 2 hours, sealed and stored in dark conditions for 24 hours, and then irradiated with ultraviolet light with a wavelength of 365nm for 5 to 20 minutes to make the even The composite of azobenzene derivatives and black phosphorus nanosheets changed from E configuration to Z configuration, and the isomerization rate constant of Z-to-E of azobenzene derivatives was measured by UV-visible spectroscopy.

Embodiment 2

[0037] The basic steps are roughly the same as in Example 1. The difference is that the azobenzene derivative AB-OC with an amino terminal group is used 4 h 8 -NH 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com