Preparation method of macromolecular crosslinking agent for guanidine gum fracturing fluid

A macromolecular cross-linking agent, guar gum fracturing fluid technology, applied in chemical instruments and methods, drilling composition and other directions, can solve the problem of low temperature resistance of fracturing fluid system, large amount of cross-linking agent, guar gum The problem of large dosage, etc., to achieve the effect of reducing dosage, improving utilization efficiency, and small dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

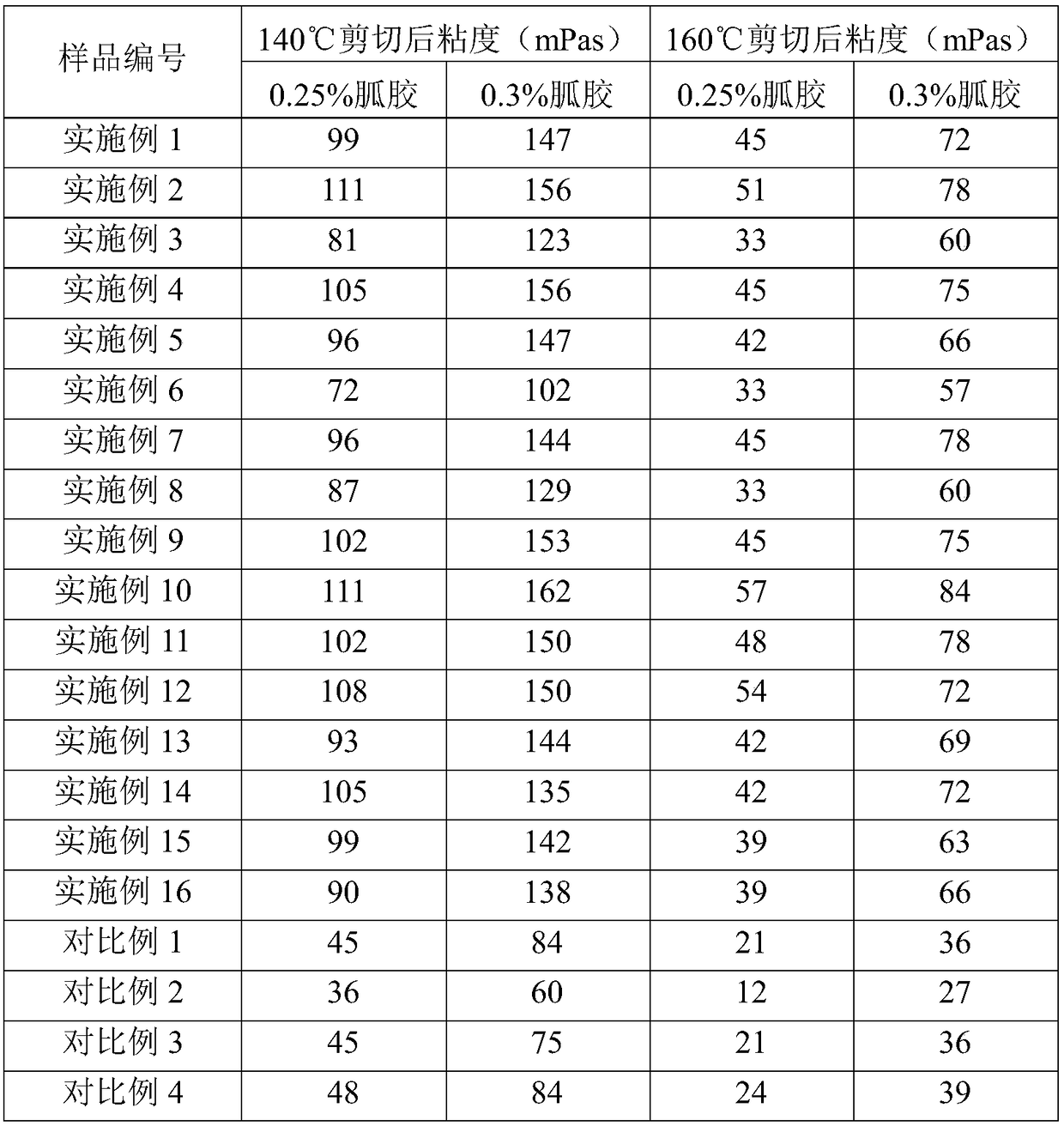

Examples

preparation example Construction

[0011] (1) Preparation of hydroxymethyl tannic acid

[0012] Add tannic acid, formaldehyde solution (40% concentration), sodium carbonate, water and methanol into a three-neck glass bottle equipped with a stirrer and a spherical condenser, pass N 2 Stir for 30min, control the temperature at 35~65℃, react for 1~20h, evaporate the solvent to dryness, and get it; the molecular weight of tannic acid is 800~2500; the mass of tannic acid, formaldehyde solution, sodium carbonate, water and methanol The ratio is 1:(0.1~5):(0.02~0.35):(0.1~10):(3~40).

[0013] (2) Preparation of Aminated Tannic Acid Matrix

[0014] Add hydroxymethyl tannic acid, polyethylene polyamine, methanol and n-butanol into a three-necked glass bottle equipped with a stirrer and a spherical condenser, pass N 2 Stir for 30min, control the temperature at 60~110°C, react for 1~15h, and evaporate the solvent to dryness to obtain; the mass ratio of hydroxymethyl tannic acid, polyvinylpolyamine, methanol and n-butano...

specific Embodiment approach

[0037] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0038] The materials, reagents, etc. used in the following examples can be obtained from commercial sources unless otherwise specified.

[0039] The present invention will be further described below with reference to specific embodiments, but the protection scope of the present invention is not limited thereto.

Embodiment 1

[0041] A preparation method of a macromolecular cross-linking agent for guar gum fracturing fluid, comprising the following steps:

[0042] (1) Preparation of hydroxymethyl tannic acid

[0043] Add 10g tannic acid (molecular weight is 1300), 12g formaldehyde solution (40% concentration), 1g sodium carbonate, 5g water, 150g methanol into the three-neck glass bottle equipped with agitator and spherical condenser, pass N 2 Stir for 30min, control the temperature at 45°C, react for 6h, and evaporate the solvent to dryness to obtain hydroxymethyl tannic acid.

[0044] (2) Preparation of Aminated Tannic Acid Matrix

[0045] Add 10g of hydroxymethyl tannic acid, 20g of tetraethylenepentamine, 40g of methanol, and 100g of n-butanol into a three-neck glass bottle equipped with a stirrer and a spherical condenser, pass N 2Stir for 30min, control the temperature at 80°C, react for 4h, and evaporate the solvent to dryness to obtain an aminoated tannic acid matrix.

[0046] (3) Preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com