Enzyme-free glucose photoelectrochemical sensor, and detection method of enzyme-free glucose concentration

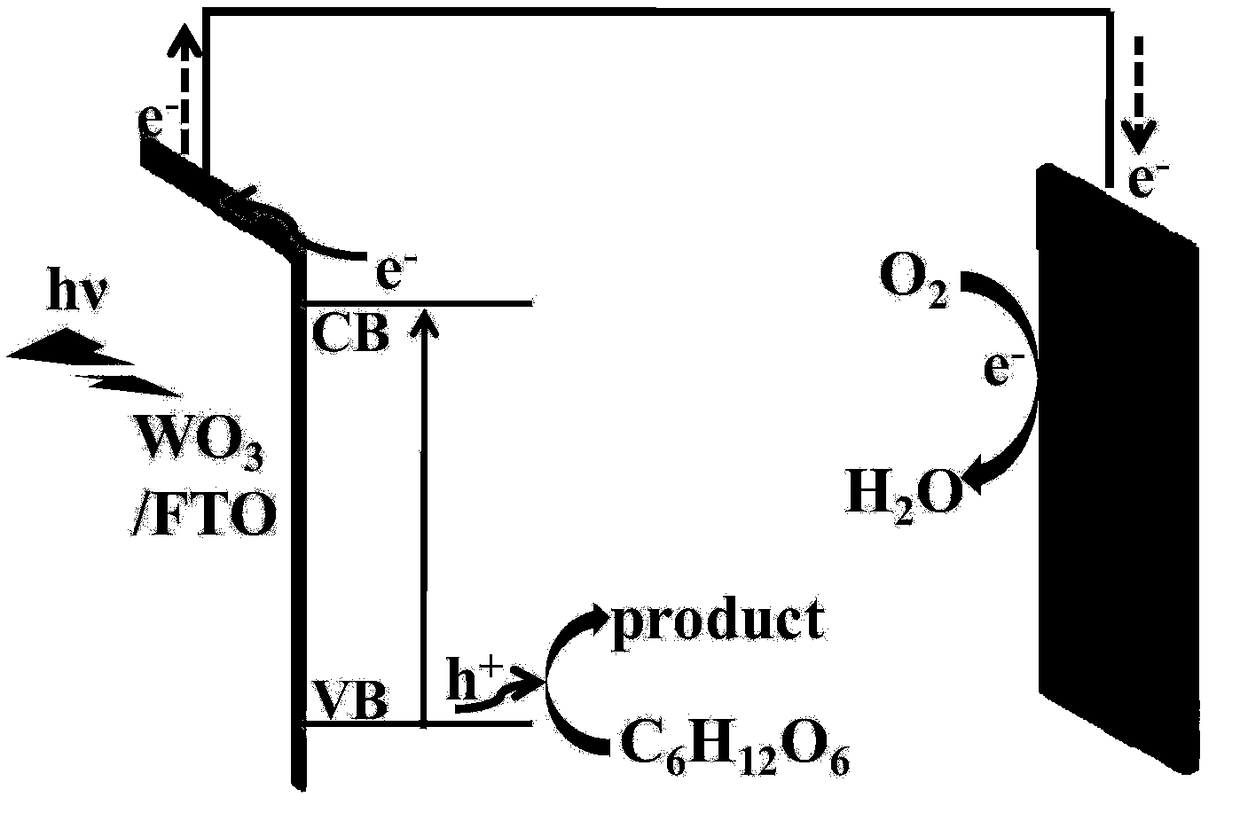

A glucose concentration and photoelectrochemical technology is applied in the field of glucose analysis and testing, which can solve the problems such as the difficulty of long-term fixation of glucose oxidase, the influence of glucose detection results, and the unsuitability for detection, and achieves low detection signal background, simplified sample processing, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

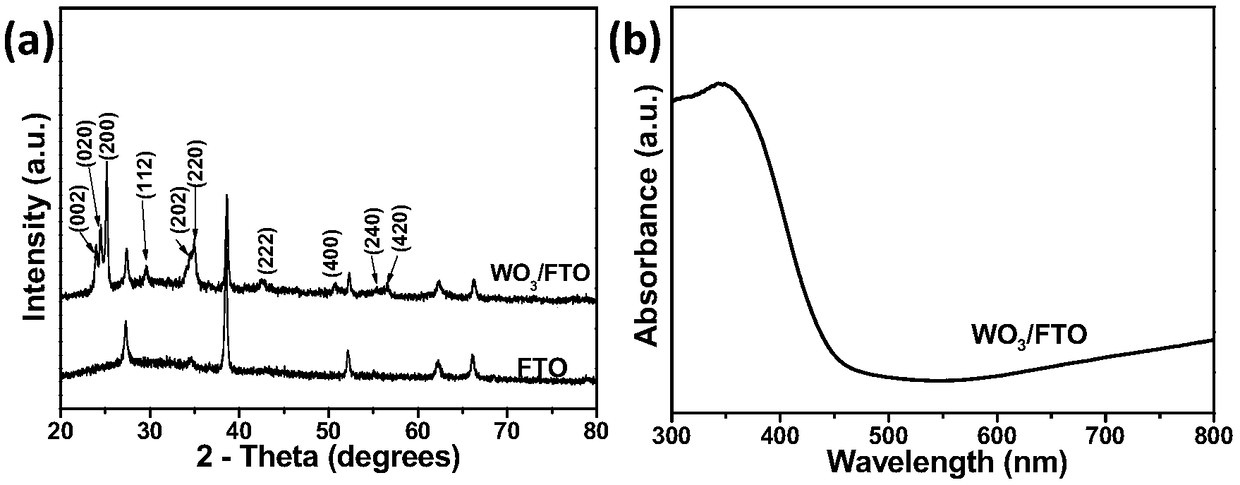

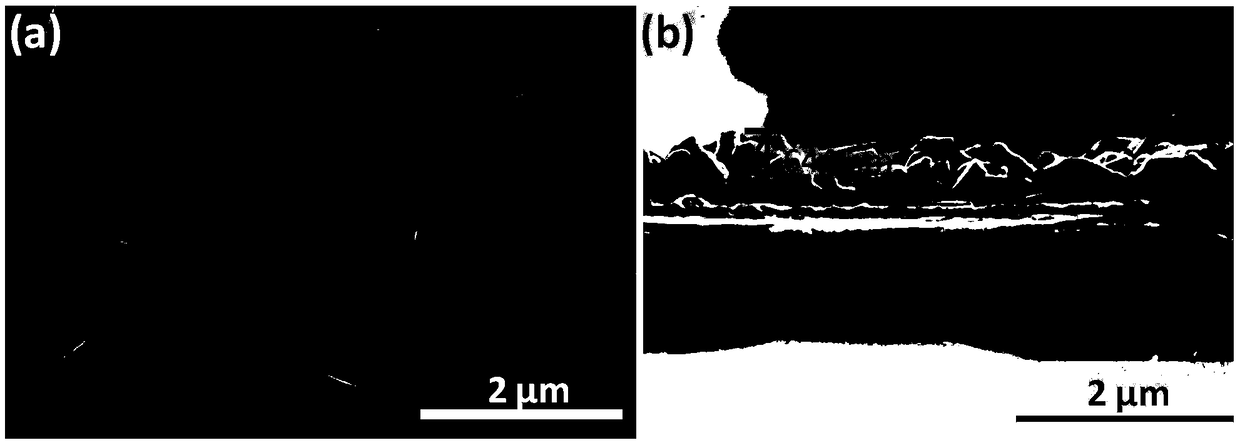

[0039] A kind of WO 3 A method for preparing a photoanode, comprising:

[0040] a. Cut the FTO conductive glass into a size of 2 cm × 2.5 cm, first boil it in 5% sodium hydroxide solution, and then use acetone, ethanol and ultrapure water to ultrasonically clean the FTO;

[0041] b. Take 1.2mmolNa 2 WO 4 2H 2 O solution and 1.2mmol ammonium oxalate were dissolved in 33mL of deionized water, and 9mL of 36.5% hydrochloric acid was added to obtain a yellow tungstic acid precipitate. After stirring for 10 minutes, 8mL of 30% H 2 o 2 , the precipitate was dissolved and a clear peroxytungstic acid solution was obtained, then 30mL of ethanol was added and the stirring was continued for 10 minutes, then the cleaned conductive substrate was leaned against the wall of the beaker and placed in a water bath at 85°C for 150 minutes. During this process, A uniform tungstic acid film is slowly grown on the FTO substrate, and the above tungstic acid film is rinsed with deionized water an...

Embodiment 2

[0044] A kind of WO 3 A method for preparing a photoanode, comprising:

[0045] a. Cut the FTO conductive glass into a size of 2 cm × 2.5 cm, first boil it in 5% sodium hydroxide solution, and then use acetone, ethanol and ultrapure water to ultrasonically clean the FTO;

[0046] b. Take 0.5mmolNa 2 WO 4 2H 2 O solution and 0.5mmol ammonium oxalate were dissolved in 33mL of deionized water, and 5mL of 36.5% hydrochloric acid was added to obtain a yellow tungstic acid precipitate. After stirring for 10 minutes, 6mL of 30% H 2 o 2 , the precipitate was dissolved and a clear peroxytungstic acid solution was obtained, then 30mL of ethanol was added and the stirring was continued for 10 minutes, then the cleaned conductive substrate was leaned against the wall of the beaker and placed in a water bath at 75°C for 120 minutes. During this process, A uniform tungstic acid film is slowly grown on the conductive substrate, and the above tungstic acid film is rinsed with deionized w...

Embodiment 3

[0049] A kind of WO 3 A method for preparing a photoanode, comprising:

[0050] a. Cut the FTO conductive glass into a size of 2 cm × 3.5 cm, first boil it in 5% sodium hydroxide solution, and then use acetone, ethanol and ultrapure water to ultrasonically clean the FTO;

[0051] b. Take 1.5mmolNa 2 WO 4 2H 2 O solution and 1.5mmol ammonium oxalate were dissolved in 33mL of deionized water, and 10mL of 36.5% hydrochloric acid was added to obtain a yellow tungstic acid precipitate. After stirring for 10 minutes, 10mL of 30% H 2 o 2 , the precipitate was dissolved and a clear peroxytungstic acid solution was obtained, then 30mL of ethanol was added and stirring continued for 10 minutes, then the cleaned conductive substrate was leaned against the wall of the beaker and placed in a water bath at 85°C for 170 minutes. During this process, A uniform tungstic acid film is slowly grown on the conductive substrate, and the above tungstic acid film is rinsed with deionized water a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com