A lithium sulfur battery, a separator thereof, and a preparation method of the separator

A lithium-sulfur battery and porous membrane technology are applied in the field of lithium-sulfur battery and its separator and the preparation of the separator, which can solve the problems of poor battery rate performance, need to be further improved, low mechanical strength, etc. Shuttle effect, the effect of improving battery safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

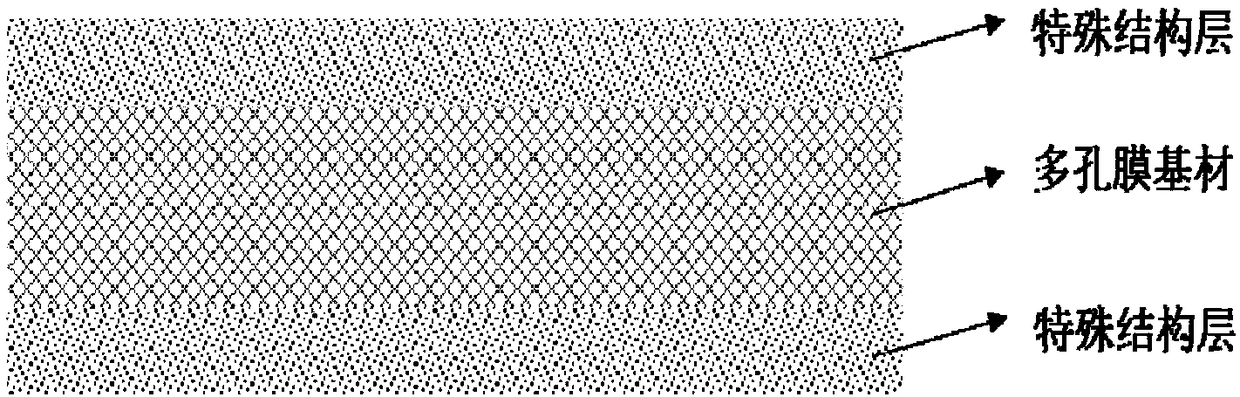

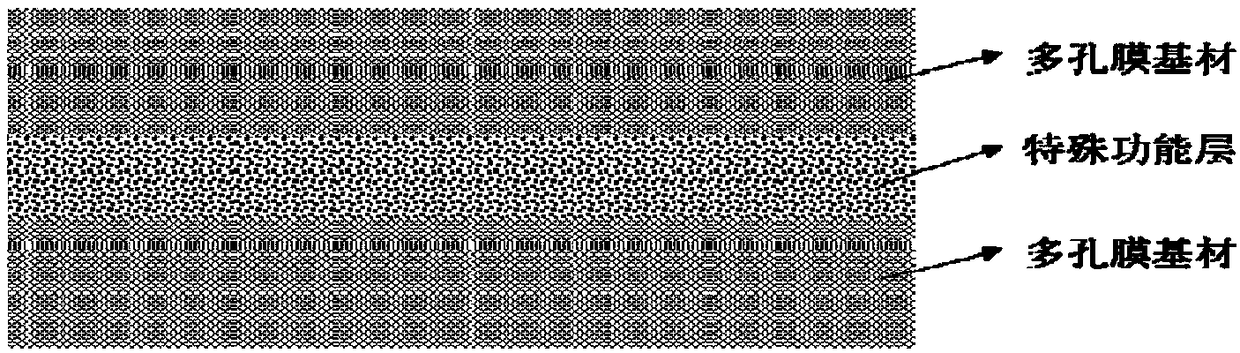

[0038] A functional membrane for lithium-sulfur batteries of the present invention comprises a porous membrane substrate, the surface of which is provided with a functional structure layer, and the components of the functional structure layer include a filler, an adhesive and a lithium-conducting Sub-functional additives, wherein the filler is MoS2, and its added amount is 40% of the total weight of the functional structure layer. The adhesive is phenylacrylic acid, and the amount of the adhesive is 30% of the total weight of the functional structure layer. The lithium ion-conducting functional additive is modified polyethylene oxide, and its addition amount is 30% of the total weight of the functional structural layer.

[0039] The preparation method of the functional film for lithium-sulfur batteries in this embodiment includes the following process: mixing the raw materials of each component of the functional structural layer with the solvent (ethanol) through high-speed di...

Embodiment 2

[0041] A functional membrane for lithium-sulfur batteries of the present invention comprises a porous membrane substrate, the surface of which is provided with a functional structure layer, and the components of the functional structure layer include a filler, an adhesive and a lithium-conducting Sub-functional auxiliary agent, wherein the filler is graphene, and its added amount is 48% of the total weight of the functional structure layer. The adhesive is polyurethane acrylate, and the amount of the adhesive is 27% of the total weight of the functional structure layer. The lithium-ion guiding functional assistant is poly(ethylene glycol) methyl ether acrylate and styrene sulfonate, and its addition amount is 25% of the total weight of the functional structural layer.

[0042] The preparation method of the functional film for the lithium-sulfur battery of this embodiment includes the following process: the raw materials of each component of the functional structural layer and ...

Embodiment 3

[0044] A functional membrane for lithium-sulfur batteries of the present invention comprises a porous membrane substrate, the surface of which is provided with a functional structure layer, and the components of the functional structure layer include a filler, an adhesive and a lithium-conducting Sub-functional auxiliary agent, wherein the filler is iron sulfide, and its added amount is 15% of the total weight of the functional structural layer. The adhesive is styrene-butadiene latex, and the amount of the adhesive is 40% of the total weight of the functional structural layer. The described lithium-ion guiding functional additive is (like) Nafion (DuPont, USA) medium, and its addition amount is 45% of the total weight of the functional structural layer.

[0045] The preparation method of the functional film for lithium-sulfur batteries in this embodiment includes the following process: mixing the raw materials of each component of the functional structural layer with the solv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com