Method for etching super-hydrophobic aluminum alloy surface by laser and alkali solution recombination

A technology of aluminum alloy surface and laser etching, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of uncontrollable surface quality and poor hydrophobicity of chemical etching, and achieve stable and long-term superhydrophobic performance, Strong self-cleaning performance, not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The method for combined etching of superhydrophobic self-cleaning aluminum alloy surface by infrared laser and alkali solution in this embodiment comprises the following steps:

[0038] (1) Pretreatment: The 1060 aluminum alloy sample of 20mm×20mm×2mm was ultrasonically cleaned with absolute ethanol and distilled water in sequence, the cleaning temperature was 60°C, and the single cleaning was 4min, and the drying condition was a constant temperature of 120°C Dry in an oven for 15 minutes to obtain a pretreated aluminum alloy;

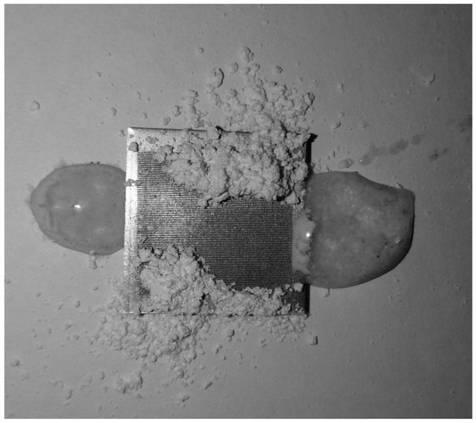

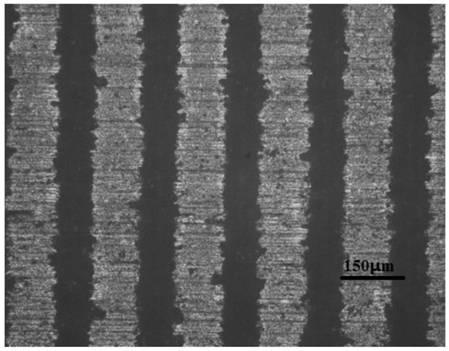

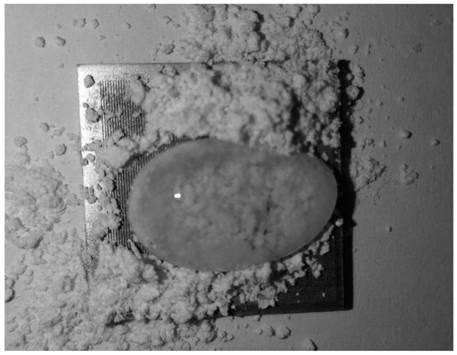

[0039] (2) Laser etching: use an infrared laser marking machine to etch the microstructure on the surface of the pretreated aluminum alloy obtained in step (1). The process parameters for laser etching are: laser power 30w, laser frequency 20kHz, laser wavelength 1064nm, scan speed 100mm s -1 , The scanning distance is 200 μm, and the grating-like microstructure is etched to obtain laser-etched aluminum alloy;

[0040] (3) Pre-treatment of alk...

Embodiment 2

[0046] The method for combined etching of superhydrophobic self-cleaning aluminum alloy surface by infrared laser and alkali solution in this embodiment comprises the following steps:

[0047] (1) Pretreatment: 1060 aluminum alloy samples of 20 mm × 20 mm × 2 mm were ultrasonically cleaned using absolute ethanol and distilled water in sequence, the cleaning temperature was 70 ° C, and the single cleaning time was 10 min. The drying condition was a constant temperature of 145 ° C Dry in an oven for 30 minutes to obtain a pretreated aluminum alloy;

[0048] (2) Laser etching: use an infrared laser marking machine to etch the microstructure on the surface of the pretreated aluminum alloy obtained in step (1). The process parameters for laser etching are: laser power 30w, laser frequency 20kHz, laser wavelength 1064nm, scan speed 100mm s -1 , The scanning distance is 200 μm, and the grating-like microstructure is etched to obtain laser-etched aluminum alloy;

[0049] (3) Pre-tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com