Preparation of cationic taro starch flocculant with high-efficiency decolorization performance

A taro starch, cationic technology, applied in the field of preparation of new cationic taro starch flocculants, can solve the problems of large influence of environmental conditions, narrow application range, large sludge volume, etc. The effect of wide and strong adsorption and bridging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

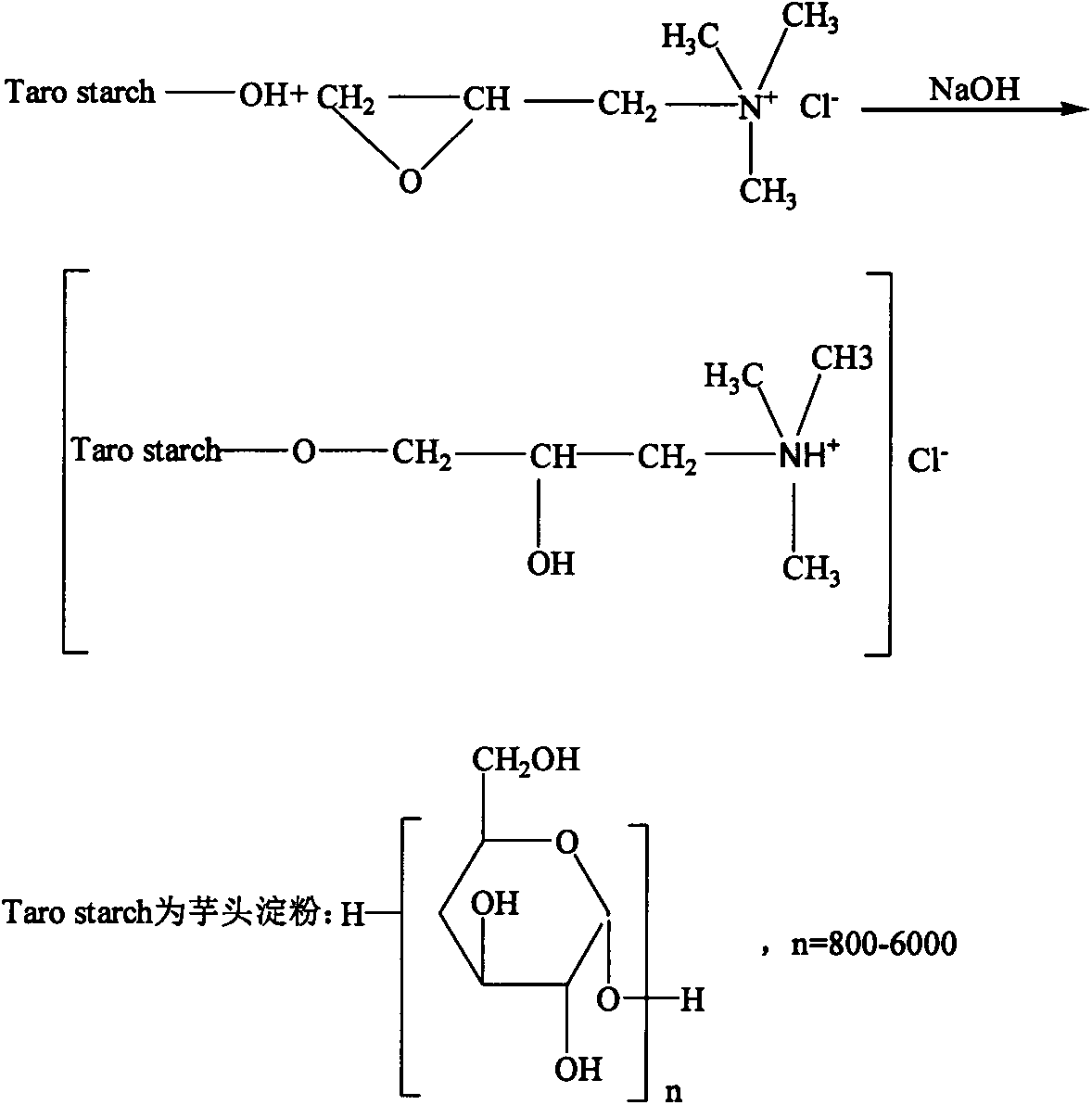

[0031] (1) Wash the taro bulbs with deionized water, peel them, cut them into thin slices, control the ratio of material to water to 1:3, adjust the pH to 10 with 0.1mol / L NaOH, and homogenize them in a plant tissue masher for 5 -10min, pass through 80-mesh and 260-mesh sieves respectively, after the filtrate settles for 48h, centrifuge at 4000r / min, take the precipitate, wash it several times with deionized water, and place it under 40°C for vacuum drying to obtain taro starch.

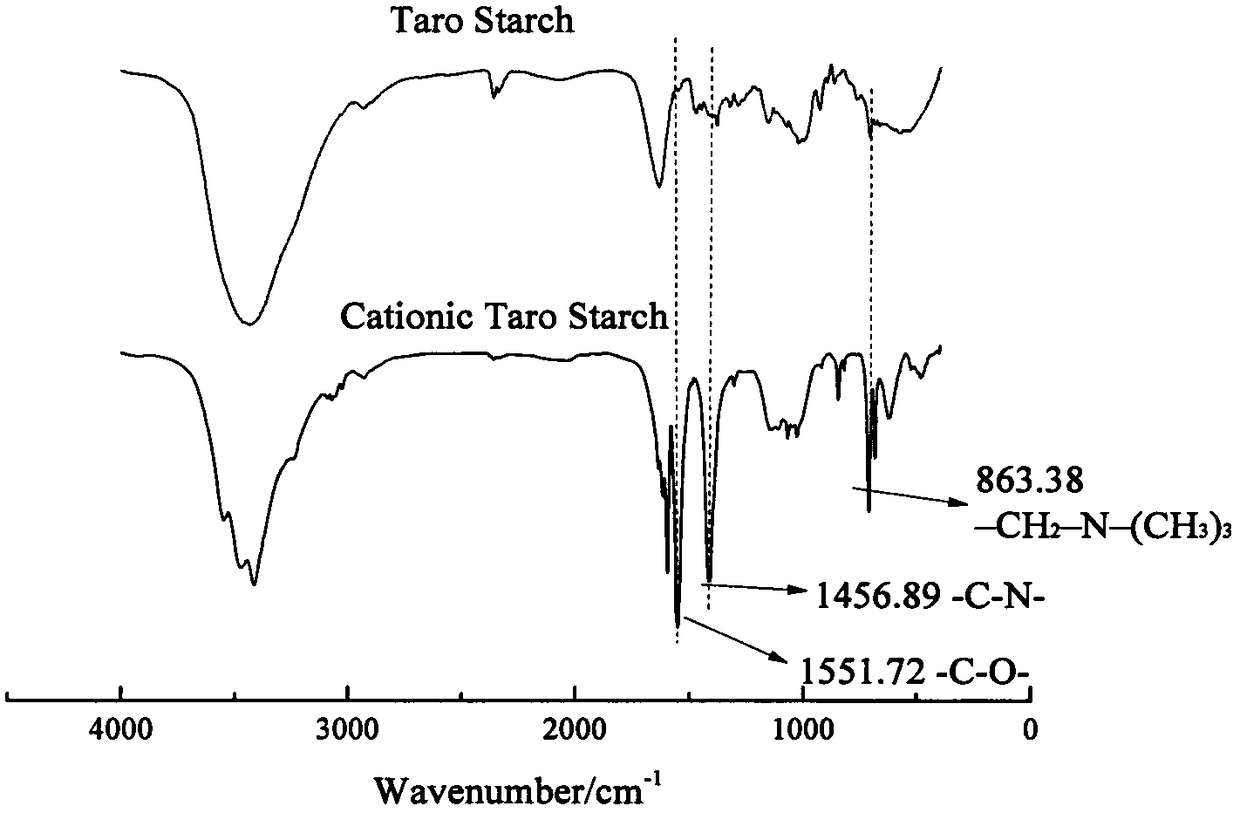

[0032] (2) Put the above-mentioned taro starch into the mixing tank, and the dissolving amount is taro starch consumption 1.8wt% basic catalyst NaOH and 18wt% cationic etherification agent 2,3-epoxypropyl trimethyl chloride Ammonium, after activation for 10 minutes, sprayed into taro starch, stirred for 30 minutes, sealed the mixture, reacted at 55°C for 2.6 hours, washed and dried with 80% ethanol or acetone to obtain cationic taro starch flocculant.

Embodiment 2

[0034] (1) Wash the taro bulbs with deionized water, peel them, cut them into thin slices, control the feed-water ratio to 1:2, adjust the pH to 9.5 with 0.1mol / L NaOH, and homogenize them in a plant tissue masher for 5 -10min, pass through 80-mesh and 260-mesh sieves respectively, after the filtrate settles for 48h, centrifuge at 4000r / min, take the precipitate, wash it several times with deionized water, and place it under 40°C for vacuum drying to obtain taro starch.

[0035] (2) Put the above-mentioned taro starch into the mixing tank, and the dissolving amount is taro starch consumption 1.8wt% basic catalyst NaOH and 18wt% cationic etherification agent 2,3-epoxypropyl trimethyl chloride Ammonium, after activation for 10 minutes, sprayed into taro starch, stirred for 30 minutes, sealed the mixture, reacted at 55°C for 2.6 hours, washed and dried with 80% ethanol or acetone to obtain cationic taro starch flocculant.

Embodiment 3

[0037] (1) Wash the taro bulbs with deionized water, peel them, cut them into thin slices, control the ratio of material to water to 1:3, adjust the pH to 10 with 0.1mol / L aOH, and homogenize them in a plant tissue masher for 5 -10min, pass through 80-mesh and 260-mesh sieves respectively, after the filtrate settles for 48h, centrifuge at 4000r / min, take the precipitate, wash it several times with deionized water, and place it under 40°C for vacuum drying to obtain taro starch.

[0038](2) Put the above-mentioned taro starch into the mixing tank, and the dissolving amount is taro starch consumption 2wt% alkaline catalyst NaOH and 16wt% cationic etherifying agent 2,3-epoxypropyltrimethylammonium chloride After activation for 10 minutes, spray into taro starch, stir for 30 minutes, seal the mixture, react at 60°C for 2 hours, wash and dry with 80% ethanol or acetone to obtain cationic taro starch flocculant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com