Preparation method of modified natural chitin bio-based high-performance polycarboxylate superplasticizer

A technology of chitin and polycarboxylate, which is applied in the field of preparation of modified natural chitin bio-based high-performance polycarboxylate water reducers, can solve the problems of limited sources of artificial chemicals, high prices, and health hazards, and achieve Excellent fluidity, maintaining performance, broadening the source of raw materials, and reducing the effect of negative impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

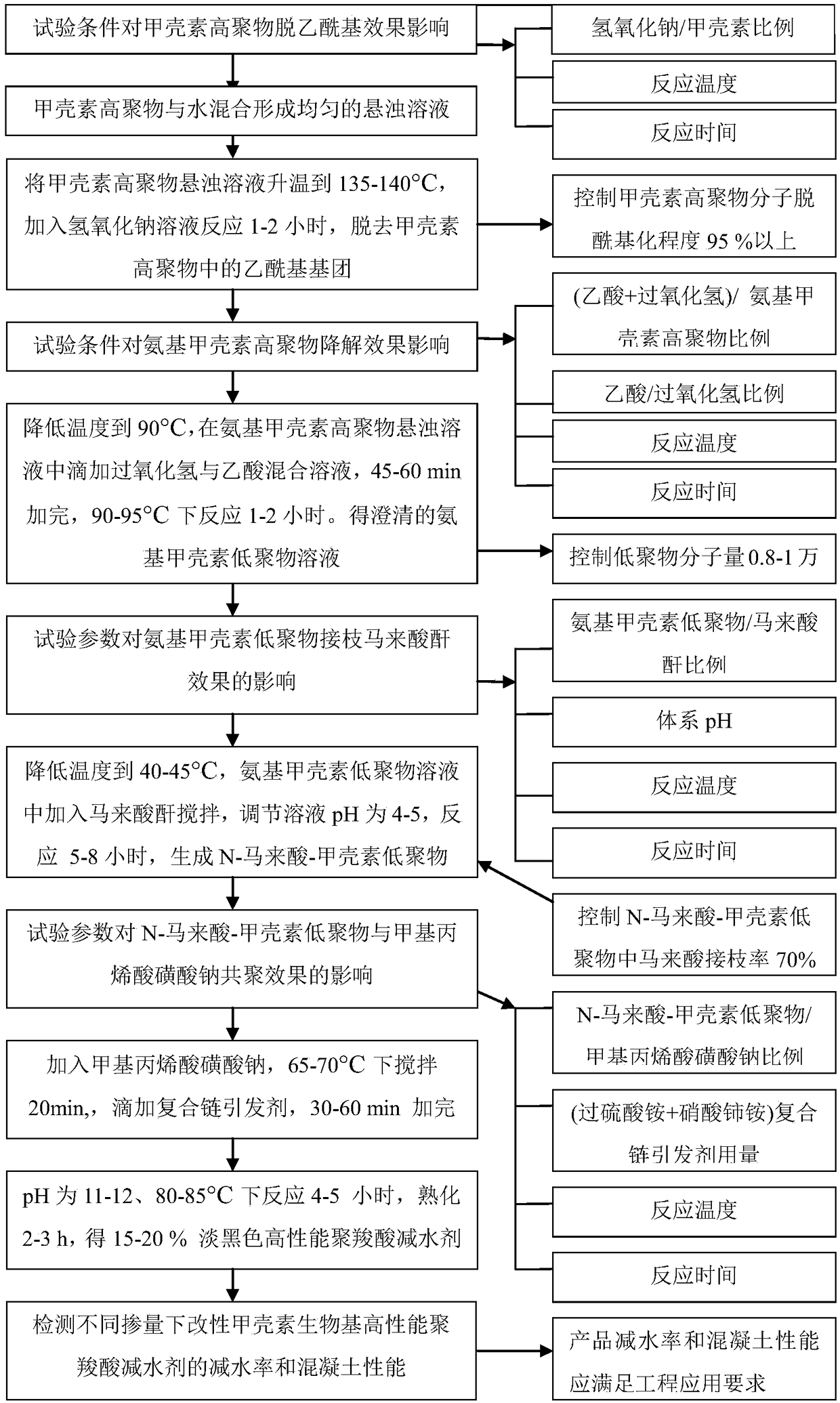

Method used

Image

Examples

Embodiment 1

[0041] 1. Preparation of modified natural chitin bio-based high-performance polycarboxylate superplasticizer

[0042] 1.1. Preparation of amino chitin polymer

[0043] The chitin high polymer (weight average molecular weight: 335,400) of Nantong Langshan Xingcheng Biochemical Products Factory was used as a raw material. Weigh 300kg of chitin polymer and 700kg of water into a reaction vessel equipped with a stirrer, a thermometer, a dropping funnel, and a reflux condenser. Raise the temperature to 80°C and stir to form a uniform suspension solution. Raise the temperature to 138°C, add 1170kg of sodium hydroxide solution (50% by weight) to the chitin high polymer suspension solution for deacetylation, stir at 138°C for 1.5 hours, and generate carapace containing amino groups Chitin high polymer (concentration is 20-25%), control the degree of deacylation in the chitin high polymer molecule to more than 95%.

[0044] 1.2. Degradation of chitin polymer

[0045] Lower the tempe...

Embodiment 2

[0051] 2. Preparation of modified natural chitin bio-based high-performance polycarboxylate superplasticizer

[0052] 2.1. Preparation of aminochitin polymer

[0053] The chitin high polymer (weight average molecular weight: 335,400) of Nantong Langshan Xingcheng Biochemical Products Factory was used as a raw material. Weigh 330kg of chitin polymer and 670kg of water into a reaction vessel equipped with a stirrer, a thermometer, a dropping funnel, and a reflux condenser. Raise the temperature to 80°C and stir to form a uniform suspension solution. Raise the temperature to 138°C, add 1185kg of sodium hydroxide solution (50% by weight) to the chitin high polymer suspension solution for deacetylation treatment, stir at 135°C for 2 hours, and generate carapace containing amino groups Chitin high polymer (concentration is 20-25%), control the degree of deacylation in the chitin high polymer molecule to more than 95%.

[0054] 2.2. Degradation of chitin polymer

[0055] Lower th...

Embodiment 3

[0061] 3. Preparation of modified natural chitin bio-based high-performance polycarboxylate superplasticizer

[0062] 3.1. Preparation of aminochitin polymer

[0063] The chitin high polymer (weight average molecular weight: 335,400) of Nantong Langshan Xingcheng Biochemical Products Factory was used as a raw material. Weigh 350kg of chitin polymer and 660kg of water into a reaction vessel equipped with a stirrer, a thermometer, a dropping funnel, and a reflux condenser. Raise the temperature to 80°C and stir to form a uniform suspension solution. Raise the temperature to 1140°C, add 1200kg of sodium hydroxide solution (50% by weight) to the chitin high polymer suspension solution for deacetylation treatment, stir at 140°C for 1 hour, and generate carapace containing amino groups Chitin high polymer (concentration is 20-25%), control the degree of deacylation in the chitin high polymer molecule to more than 95%.

[0064] 3.2. Degradation of chitin polymer

[0065]Lower the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| sand rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com