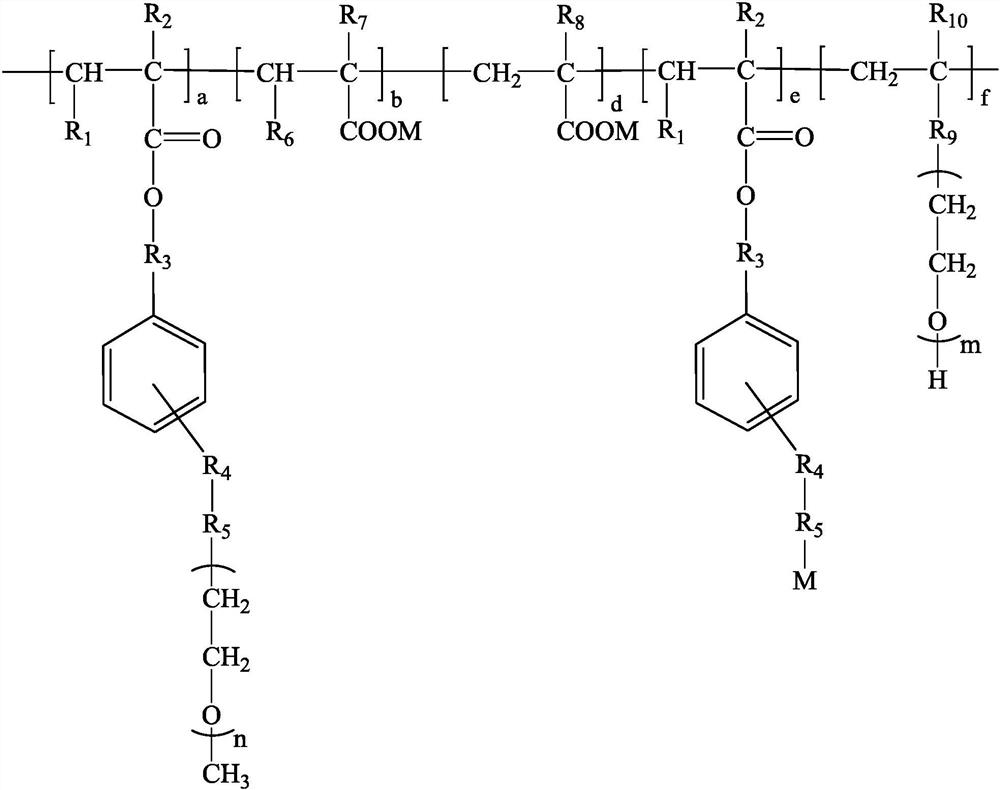

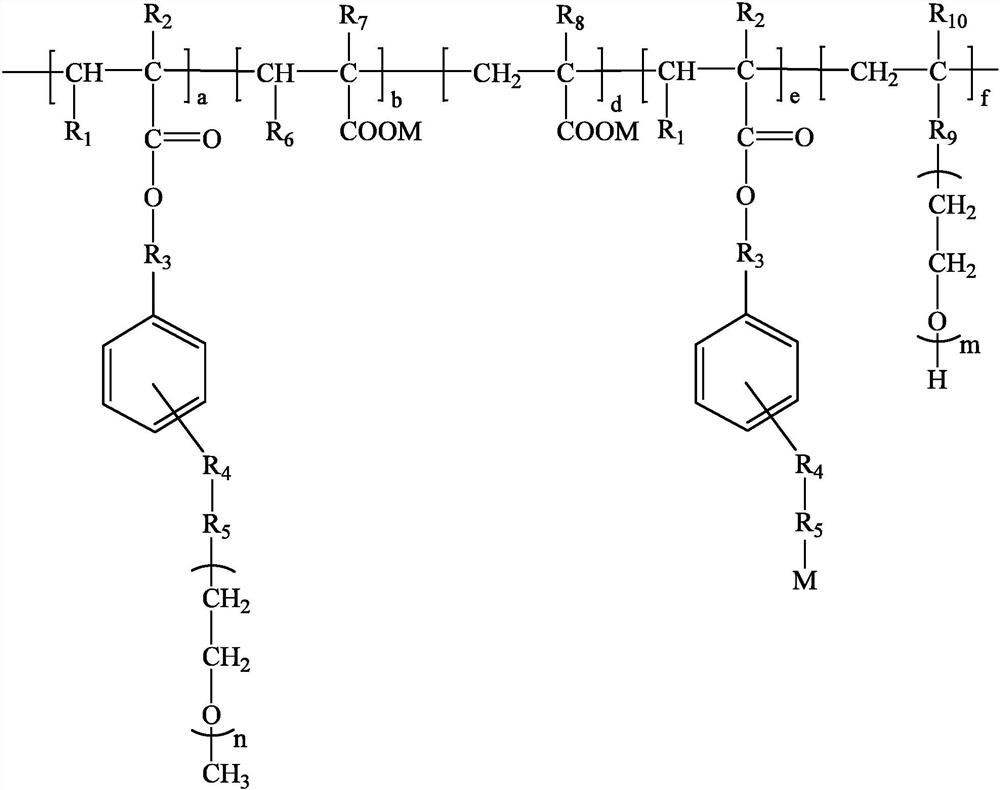

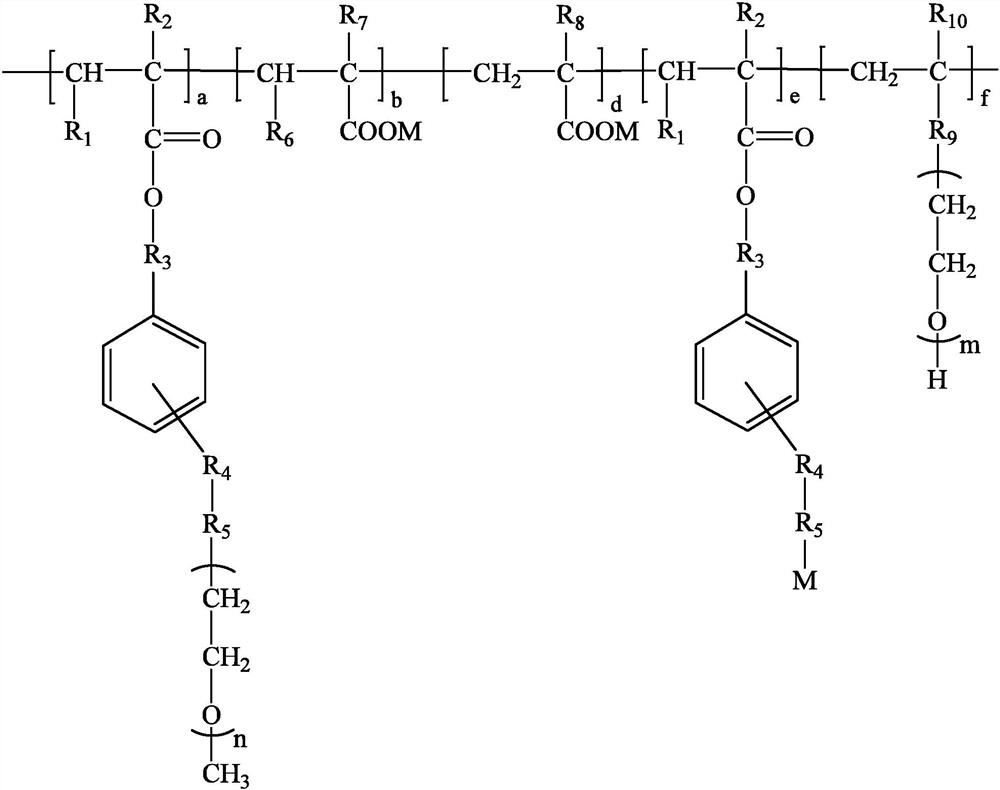

A shrinkage-reducing polycarboxylate water reducer and its preparation method

A technology of polycarboxylic acid and water reducing agent, which is applied in the field of construction admixtures, can solve problems such as poor workability, insufficient water reducing rate, and poor slump retention, and achieve conformational stretching, reducing concrete shrinkage, and large molecular size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Esterification reaction: Mix 120.00g of methoxypolyethylene glycol with a molecular weight of 1200 and 27.00g of p-hydroxybenzoic acid, under the protection of nitrogen, heat up to 110°C, add 1.60g of p-toluenesulfonic acid, and keep warm for 1.5 h, lower the temperature to 70°C, add 60.00g of acrylic acid, 1.25g of 4-hydroxy-2,2,6,6-tetramethylpiperidine-1-oxyl radical and 0.50g of the second catalyst, keep the reaction for 2.5h, during which The method of vacuumizing with water is used to remove water, and after the reaction is completed, it is lowered to room temperature to obtain the first mixture containing esterification product and unreacted acrylic acid;

[0032] (2) Monomer blending: 100.00g of the first mixture prepared in step (1), 2.00g of 2-(trifluoromethyl)acrylic acid and 100.00g of 2-methacryl polyethylene glycol ether with a molecular weight of 2400 Mix, and add 100.00g water to make it dissolve, obtain comonomer mixture solution;

[0033](3) Copol...

Embodiment 2

[0036] (1) Esterification reaction: Mix 200.00g of methoxypolyethylene glycol with a molecular weight of 2000 and 35.00g of p-hydroxymethylbenzoic acid, under the protection of nitrogen, heat up to 120°C, add 2.80g of benzenesulfonic acid, and keep warm for reaction 1.5h, cool down to 80°C, add 60.00g of methacrylic acid, 0.90g of 2,2-di(4-tert-octylphenyl)-1-picrylhydrazyl radical and 0.8g of the second catalyst, keep the reaction for 3.0h During the process, water is removed by the method of purging nitrogen with water, and the reaction is cooled to room temperature after completion of the reaction to obtain the first mixture containing esterified product and unreacted methacrylic acid;

[0037] (2) Monomer blending: 100.00 g of the first mixture prepared in step (1), 3.00 g of 2-fluoroacrylic acid and 100.00 g of 3-methyl-3-butenyl polyethylene glycol ether with a molecular weight of 3000 were mixed , and add 100.00g water to make it dissolve to obtain a comonomer mixture s...

Embodiment 3

[0041] (1) Esterification reaction: Mix 240.00g of methoxypolyethylene glycol with a molecular weight of 2400 and 40.00g of p-hydroxybenzenesulfonic acid, under the protection of nitrogen, heat up to 125°C, add 6.80g of p-toluenesulfonic acid, and keep warm for the reaction 2.0h, cool down to 75°C, add 35.00g of maleic acid, 25.00g of acrylic acid, 0.60g of 4-hydroxy-2,2,6,6-tetramethylpiperidine-1-oxyl radical and 1.00g of the second catalyst, Insulation reaction for 1.5h, during which the water was removed by vacuuming with water, and after the reaction was completed, it was lowered to room temperature to obtain the first mixture containing the esterification product and unreacted maleic acid and unreacted acrylic acid;

[0042] (2) Monomer blending: 100.00g of the first mixture prepared in step (1), 4.00g of 2-(trifluoromethyl)acrylic acid and 100.00g of 2-propenyl polyethylene glycol ether with a molecular weight of 1200 were mixed, And add 100.00g water to make it dissolv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com