Durable super-hydrophilic or super-hydrophobic plastic surface and preparation method thereof

A super-hydrophilic and super-hydrophobic technology, applied in the coating and other directions, can solve the problems of not reaching the super-lyophobic state, no test instructions for durability, etc., achieving good industrial application prospects, strong durability, and simple and convenient preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

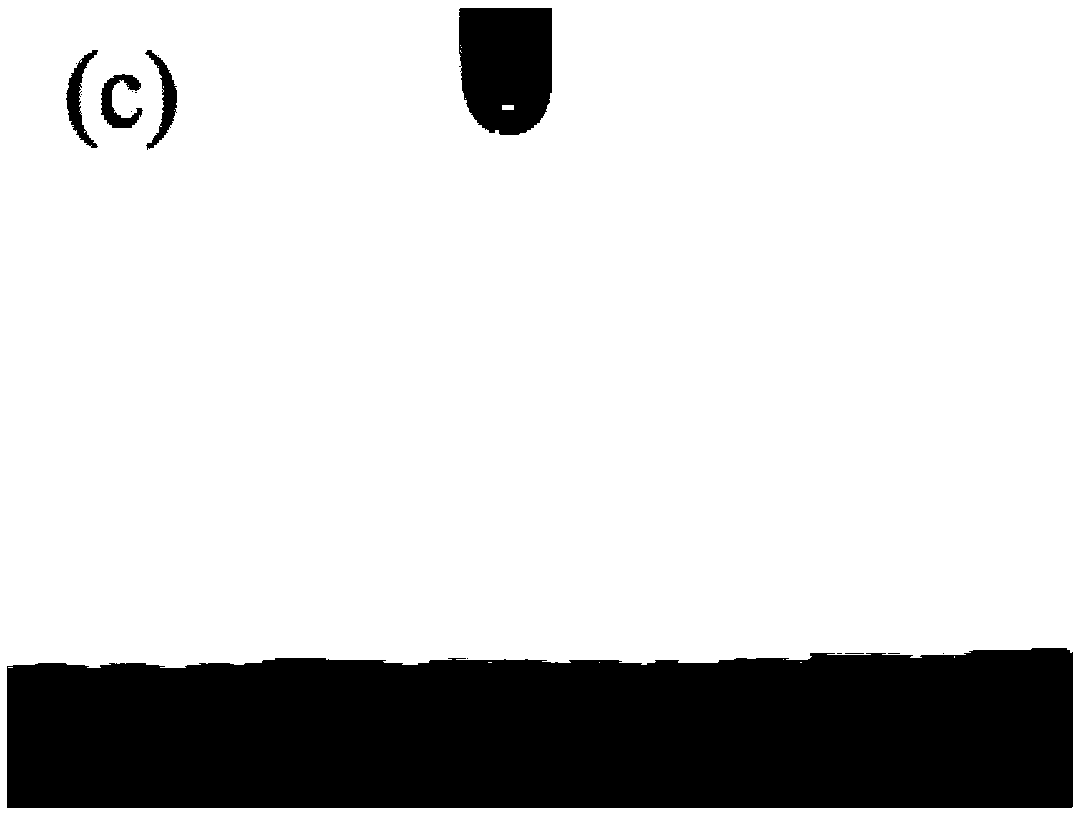

[0046] The preparation of durable super-hydrophilic plastic surface specifically comprises the following steps:

[0047] (1) Etch micron-scale structures on the surface of plexiglass with a laser etching machine. The etched structure is square in shape, with a side length of 350 µm and a spacing of 700 µm; the parameters of the laser etching machine are: speed 20%, energy 20%;

[0048] (2) Clean the etched sample with ethanol, dry at 50°C, and set aside;

[0049](3) The preparation method of superhydrophilic modified silica (by weight): Take 46 parts of ethyl orthosilicate in 33 parts of ethanol solution, stir at 50 °C for 30 minutes, add 2.6 parts of ammonia water and 7.2 parts of distilled water, continue to stir at constant temperature for 8 hours, add 1.26 parts of heptadecafluorodecyltrimethoxysilane to it, and continue to keep constant temperature for 12 hours; centrifuge the obtained suspension at a speed of 6000 rpm for 10 minutes, and take out the centrifuged product...

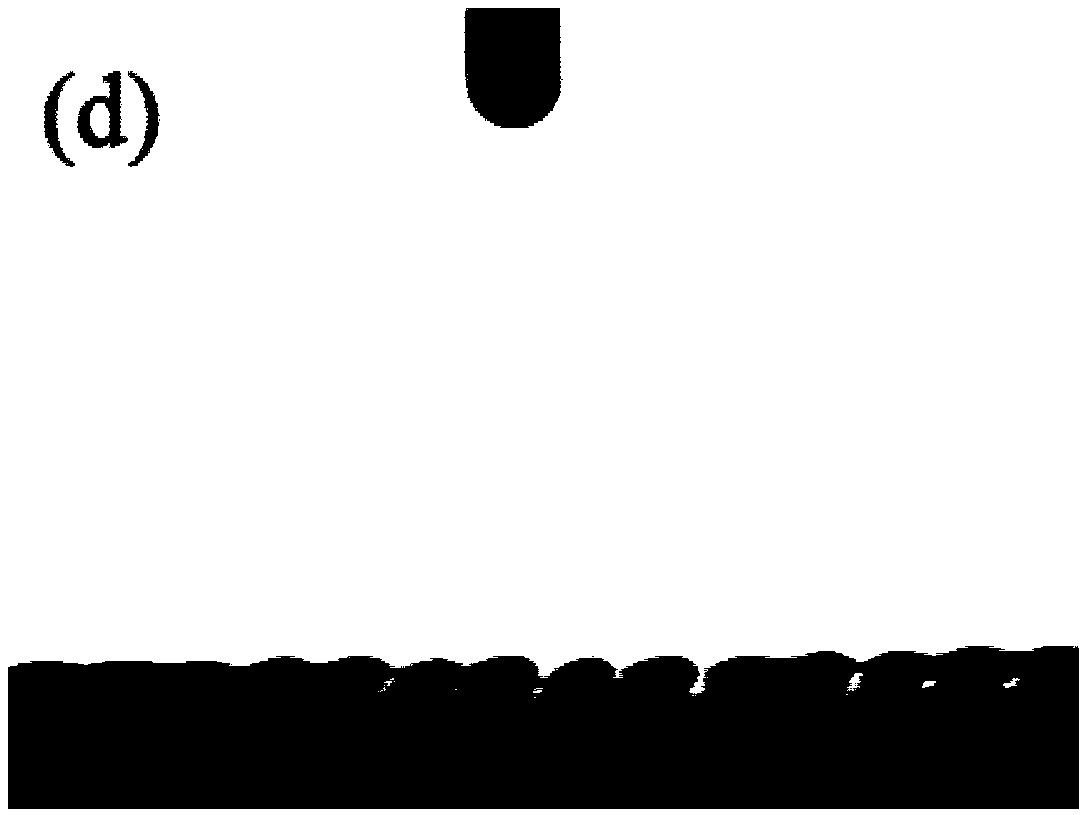

Embodiment 2

[0057] (1) Etch the micron structure on the surface of the plexiglass with a laser etching machine. The etched structure is cylindrical in shape, with a diameter of 70 µm and a pitch of 140 µm; the parameters of the laser etching machine are: speed 20%, energy 50 %;

[0058] (2) Clean the etched sample with acetone, dry at 50°C, and set aside;

[0059] (3) The preparation method of superhydrophobic modified nano-silica (by weight): Take 74 parts of tetraethyl orthosilicate in 60 parts of ethanol solution, stir at 30°C for 30 minutes, add 2.6 parts of ammonia water and 0 parts of distilled water, continue to stir at a constant temperature for 3 hours, add 1.1 parts of perfluorodecyltrichlorosilane to it, and continue to keep the temperature for 6 hours; centrifuge the obtained suspension at a speed of 6000 rpm for 10 minutes, and take out the centrifuged product nanometer Silica, cleaned with ethanol, under the same centrifugation conditions, continue to centrifuge and then wa...

Embodiment 3

[0065] (1) Use a laser etching machine to etch the micron structure on the surface of the plexiglass. The etched structure shape is a triangular truss, the side length is 140µm, and the spacing is 280µm; the parameters of the laser etching machine are: speed 20%, Energy 30%;

[0066] (2) Clean the etched sample with ethanol, dry at 50°C, and set aside;

[0067] (3) The preparation method of superhydrophilic modified nano-silica (by weight): Take 46 parts of ethyl orthosilicate in 46 parts of ethanol solution, stir at 25 °C for 30 minutes, add 5.9 parts of ammonia water and 4 parts of distilled water, continue to stir at constant temperature for 3 hours, take 1 part of heptadecafluorodecyltrimethoxysilane, add it, and continue to keep constant temperature for 12 hours; centrifuge the obtained suspension at a speed of 6000 rpm, centrifuge for 10 minutes, take out the centrifuge The product nano-silica is cleaned with ethanol, and under the same centrifugation conditions, the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com